Recycling 3D Printer Filaments: How & Which Filaments Can Be Recycled

At 3DSourced we’ve covered everything 3D printing and 3D since 2017. Our team has interviewed the most innovative 3D printing experts, tested and reviewed more than 20 of the most popular 3D printers and 3D scanners to give our honest recommendations, and written more than 500 3D printing guides over the last 5 years.

There are a lot of us out there who try every day to make our lives greener.

With growing concerns about plastics, energy use, and wasted materials, reducing our carbon footprint has never been more important.

Because of how much 3D printing relies on energy use and plastics, it’s important to know how to make the process greener. A great way of doing this is to learn which 3D printing filaments are and aren’t recyclable and to what degree.

Unfortunately, most filaments can’t be recycled in the same way as you’d recycle a soda bottle.

However, there are some methods for recycling filaments to keep in mind depending on which kind you use, all of which we’ll explain here.

Knowing which filaments you can recycle and how is imperative to reducing your carbon footprint without having to sacrifice 3D printing, and we’re going to look at all of them today.

Here we’re going to look at which 3D filaments you can recycle, and which you should avoid if you’re eco-conscious.

We’ll also look at the best ways to recycle various filaments for maximum eco-efficiency, like filament recyclers and even home composting.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Which Filaments Can Be Recycled and How?

There are quite a few recyclable 3D printer filaments out there that will help you keep your printing as green as possible.

Keep in mind that there’s no one filament that’s easily recyclable by standard means, so even though they are the greener options, you won’t be able to simply throw these in with your plastic bottles and containers and just call it a day.

Going green with 3D printing isn’t easy, but it is worth the time and effort to reduce your carbon footprint and keep your passion eco-friendly.

PLA

PLA recycling is a very easy process. It’s a highly recyclable filament, and chances are you’ve even used already recycled PLA filament if you’ve been 3D printing for a while.

While PLA and PLA-based materials like wood filament can be recycled, they can’t be mixed with other recyclable plastics.

This is because it has a different melting point than what most recycling plants handle. As a result, leftover PLA needs to be processed separately, and so many industrial plants will refuse to take it.

That’s not to say there isn’t something you can do, though.

PLA is primarily made from plant starch, meaning it is 100% biodegradable and can be composted at home. For more information on how to go about this, you can check out some good advice and guidelines here.

Failing that, you can use a filament extruder to reuse any extra PLA yourself, effectively breathing new life into what would otherwise be wasted materials.

If you 3D print often, you’ll find this is a great money-saver too, as all the little bits of material that would otherwise be wasted all add up.

PETG

PETG is not biodegradable like PLA, but it is more widely accepted by recycling centers.

It will depend on the collection rules and laws of your local service, so it’s worth checking to see if they accept PETG filaments for recycling.

If not, you may still be able to find recycling centers and plants that will accept it.

This is particularly important because PETG shares a lot of chemical similarities with more commonly recycled plastics, but will render those plastics unrecyclable by standard means if they are somehow mixed together.

In essence, if you aren’t careful with recycling your PETG, you may end up doing more harm than good.

Non-Recyclable Filaments

Unfortunately, not all 3D printer filaments are recyclable, at least not easily.

Generally speaking, thermoplastics that aren’t PLA-based are the hardest to recycle as they don’t degrade naturally and aren’t fit for general recycling.

Here are the 3D printer filaments that you should avoid if you’re eco-conscious and why, as well as some methods to make them more environmentally friendly if you’d prefer to use them while still being conscious of your carbon footprint.

Thermoplastics (ABS, Polycarbonate, and Nylon)

While PLA is a thermoplastic, its biodegradable nature means its easily reused or recycled at home. The same is not true for other thermoplastics.

ABS is a commonly used 3D printer filament.

As a thermoplastic, it is not accepted by curbside recycling, and unlike PLA, it is not biodegradable, which also makes it unsuitable for composting. The same goes for polycarbonate and Nylon, making them some of the least green filaments around.

This makes these thermoplastic filaments a bad option if you want to go eco-friendly. However, wastage can be reduced with the use of a home filament recycler.

If you have the funds or 3D print as part of your business, you can also hire private recycling contractors who do accept thermoplastics if there are any in your area. These thermoplastics are marked as Type 7 plastics, so be sure your chosen company accepts these.

If you’re taking a more eco-friendly direction in life, it will prove useful to you to become familiar with the different plastic types and their environmental impact. You can find more information here.

Do not fret, though. New research is conducted every day in making PLA-based Type 7 plastics, which will allow you to use these materials that will effectively have the same recyclable properties as PLA.

If you do have a penchant for these materials, then try to follow the steps above to reduce plastic waste and get as much as possible from these filaments.

Ceramic

While most ceramic filaments are PLA-based, they’re not as widely or easily recycled as wood or coffee filaments. While ceramic is easily recyclable on its own, PLA is not, and so it can’t be recycled once the two are combined.

Ceramic filament can, however, be recycled using a filament recycler, so don’t be discouraged if you happen to prefer using ceramic filaments but are concerned about its eco-friendliness.

Resins

While the recyclability of your resin will depend on its type, they are not widely or easily recycled in general.

Even if you are trying to dispose of your failed resin prints properly, you will need to cure them first to remove the toxicity that will further damage the environment.

If you use a resin 3D printer, we recommend using professional recycling centers and, even better, using plant-based resins instead of your standard type or brand.

Special Mention: Reusing ABS at Home

While ABS is a thermoplastic, which we’ve mentioned above, it needs its own section because it has some uses that go beyond standard or professional recycling, many of which you can do at home.

Reusing and repurposing ABS yourself will take some work but is rewarding and practical as well as eco-friendly by turning wasted material into usable tools!

By treating ABS scraps with acetone and leaving it overnight, you can make adhesive for helping with bed adhesion (though it only works on glass), glue for 3D printing projects and general use, or slurry to help fill in any gaps in your prints.

The only difference between making these three is how much leftover ABS you use. For every 50ml of acetone, you simply need to mix small snips of ABS, stir, and leave it overnight.

For this, you’ll use around 4g of ABS for the adhesive, 8g for the glue, and 20g for the slurry.

Reusing ABS like this is a great way to use an otherwise non-recyclable material while also making some useful things to help with your 3D printing!

Eco-Friendly 3D Printing Solutions

If your filament is recyclable, you’ll need to work out how.

Not all of these methods are universal, so they’re all worth keeping in mind if you regularly change your filament type.

Filament Extruders/Recyclers

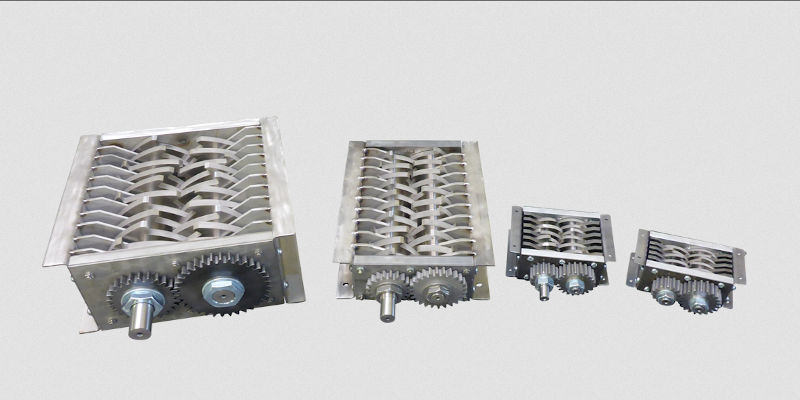

Filament extruders are excellent ways to reuse filaments and even create your own. They’re simple to use and are fantastic for taking any wasted materials and making them usable again.

As well as recycling filaments, you can use filament extruders to make some new filaments or buff yours out by using extra materials.

Personally, I recommend blending PLA with coffee grounds for filament with some very cool color diversity that’s also completely biodegradable.

You can also buy a filament shredder, which further streamlines the reusing process as well as making it easier to reuse otherwise non-recyclable materials like ABS and other non-PLA thermoplastics.

The Felfil Filament Recyclers and shredders are products we highly recommend, and can be found here.

In general, desktop extruders like the Mabelstar are great additions to any eco-friendly 3D printing enthusiast’s workstation.

Home Composting

Most PLA and PLA-based filaments are largely, if not completely, biodegradable. These include coffee, beer, and wood-based filaments.

Because they will naturally decompose, they are suitable for home composting and are ideal for use in the garden the same way you’d use hedge trimmings.

As a side, if you have a garden and haven’t started home composting yet, I highly recommend doing so.

It’s a great way to turn garden waste and food scraps into working compost and is a fantastic way to go greener with almost no effort.

It’s a far greener alternative to wastage that will also help you out with your gardening. It’s simple to start and very much worth the time.

It’s worth noting, however, that most filaments need temperatures of over 140°F to properly degrade, and so aren’t suitable for home composting.

Reducing Plastic Waste

There are a few ways to cut down on plastic waste entirely. This is especially important if you use filaments that are not easily recyclable.

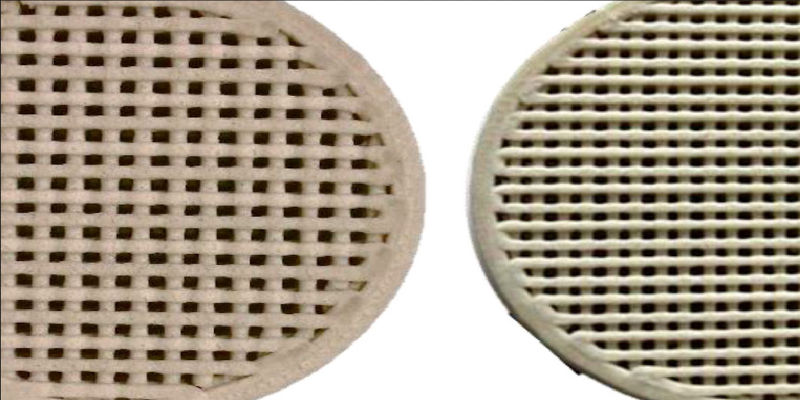

A good way to do this is with proper 3D printer maintenance. If your printer is running at maximum efficiency, then it vastly reduces the risk of warped and unusable prints, as well as cutting down on general filament waste.

Don’t forget to keep your extruder in good condition, too!

This risk is further reduced by using good quality filament and storing it properly to make sure it stays in top condition so everything runs smoothly.

You can also simply opt for projects that don’t use any more filament than necessary. By opting for well-designed STL files that require few or no supports, you’ll use less material in general for the same results.

It’s also worth noting that, as well as 3D printer maintenance, you should keep a close eye on your printer settings to ensure efficient bed adhesion.

Broken-off pieces and overheated filaments will also contribute to plastic wastage, and these seemingly insignificant fragments will add up over time if you happen to use your 3D printer regularly.

Use Eco-Friendly Materials

There’s no real point in recycling things if you don’t use recycled products yourself.

Recycling is only half the battle, after all, and we can still do our bit by simply opting for more eco-friendly and recycled materials.

There are a lot of companies out there that offer or even specialize in recycled filaments, and buying from these sources helps to support the recycling industry as well as reduce your environmental impact.

If you don’t use an FDM printer, you can also buy eco-friendly, plant-based resins like this one from Anycubic.

Just like buying recycled products, using recycled or partially recycled filaments is a good way to be more eco-friendly without expending any more effort or sacrificing quality or reliability.

Other articles you may be interested in:

- What To Do With Empty Filament Spools?

- Biodegradable filaments

- Metal Filaments: The Complete 3D Printing Guide

- PLA 3D Printing Filament – Everything You Need to Know

- HIPS Filament: The Complete HIPS 3D Printing Guide

- Paper 3D Printing: The Complete Guide

- PLA vs ABS: Which is Best for your 3D Printing Needs?

- How to Untangle a Tangled or Knotted Filament Spool