Doing Good With 3D Printing: Humanitarian Aid, Prosthetics & More Projects

At 3DSourced we’ve covered everything 3D printing and 3D since 2017. Our team has interviewed the most innovative 3D printing experts, tested and reviewed more than 20 of the most popular 3D printers and 3D scanners to give our honest recommendations, and written more than 500 3D printing guides over the last 5 years.

How is 3D printing being used to better people’s lives? How are NGOs, charities, and humanitarian aid organizations using 3D printing?

Or perhaps in short, what good is 3D printing doing for people in difficult situations now?

This article showcases how 3D printing is helping with humanitarian aid and disaster relief, emergency shelter and housing, prosthetics, and more.

3D Printing in Humanitarian Aid and Disaster Relief

The business of disaster relief is far more complex than it’s given credit for.

Moving massive amounts of supplies, equipment, and people both quickly and safely is an enormous logistical challenge that humanitarian professionals can literally spend their entire careers streamlining.

When any nation faces a humanitarian disaster, naturally, the immediate response will come from their own welfare and emergency services.

For wealthy nations, this level of support is usually sufficient, with floods, heatwaves, and terrorist actions usually being resolved domestically.

However, where additional aid could save lives, then international assistance is rarely turned down. For instance, the US received a massive international aid response during the wake of Hurricane Katrina, especially in New Orleans, where flaws in the city’s flood defenses caused 80% of the city to flood.

Despite the industry’s wealth of expertise, conventional deployments continue to face significant logistical challenges, leading to experiments with how 3D printing can help with humanitarian aid and other relief.

Logistical Challenges

Ideally, the level of humanitarian aid given would be determined by need. However, this is too often not the case. Instead, disaster zones that are cheaper and easier to get to are likely to receive more aid than remote ones.

Mike VanRooyen, a Director of the Harvard Humanitarian Initiative, explains the issue:

“So take for example, around the same time as the [2010] Haiti earthquake there was a massive flood in Pakistan. But it was very remote and very difficult to get to… The only people that could respond in this distant area of Pakistan for this massive flood were the major organizations that had lifting capacity.”

By comparison, Haiti, which is located close to the US mainland, never experienced issues with the amount of aid it received.

However, Haiti faced its own challenges receiving aid — with how it was managed and implemented.

Aid arriving into Haiti faced an enormous backlog. The quake damaged roads, ports, and underground petrol storage, forcing all urgent and heavy cargo through a single airport. This airport itself was also damaged, with its control tower inactive until days into the relief operation.

So, How Can 3D Printing Help?

Looking to get around these logistical challenges, a new way of delivering aid using 3D printing emerged. Rather than moving supplies to the location, and having to contend with remote deployments or issues with infrastructure damage, why not just 3D print supplies on-site?

Field Ready

Field Ready is a group of NGOs and charities with a vision to use 3D printing to innovate how humanitarian aid is delivered.

In an interview with Singularity University, Field Ready co-founder Dara Dotz explained that:

“If we were to order a shipping container full of umbilical cord clamps, pay the money to get the clamps, buy a million of them so we get them at a cheaper cost, put them in the shipping container… I mean, it can take anywhere from 18 months to three years, and it costs an exponential amount of money. And so, in this case, a small clinic could never afford that.”

Their approach is to instead deploy into these disaster zones and 3D print what is needed on-site, bypassing most of the logistical issues that come with the conventional method. And their approach has seen much success.

Field Ready’s Deployments

Field Ready are active across the world and make use of a variety of desktop 3D printers and manufacturing techniques. A notable and recent example of their impact is their continued work within Syria.

Over ten years of conflict has severely degraded the nation’s healthcare systems. A 2017 World Bank Damage Assessment stated that:

“More than half of all hospitals in the assessed cities have experienced some form of damage (completely destroyed or partially damaged) as of February 2017… Total damages to transportation across the cities of Aleppo, Hama and Idlib are estimated to range between US$608 million and US$668 million.”

With the conflict dragging on, Syria has struggled to rebuild this infrastructure. With locals reporting to Field Ready that “more Syrians die because of a lack of healthcare facilities and equipment than all those killed during the years of violence.”

With this in mind, Field Ready set up a workshop in the region with the intention of using 3D printing to support these damaged facilities.

Since 2020, Field Ready have been working towards adding 200 components and 35 new devices to their catalog. The catalog contains open-source designs ready to be downloaded and 3D printed.

In addition to their own manufacturing, they reached out to local partners to increase production and ultimately ensure that these devices can still be produced should Field Ready have to depart.

The merits of 3D printing’s ability to produce these parts on-demand and on-location have been proven here, especially with the additional logistical delays caused by Covid-19.

Eric James, Field Ready’s executive director noted that:

“by making these items locally, we bypass traditional supply chains and people won’t have to wait for 10 months before they can get a lifesaving device… By helping to establish a local market, we increase resilience against the shocks of future disasters. It’s practical, it’s efficient, and it saves lives.”

Since 2020 Field Ready have reported that over 13,000 people have benefitted from their deployment, with 3D printing helping them to repair over 110 medical devices, including infant incubators, microscopes, and defibrillators.

Why Is 3D Printing Not Used More for Disaster Relief?

While these projects are promising, 3D printing still has its limitations. Most 3D printing tools are slow and cannot be used on a large scale. They also have limited function in the days immediately after a disaster.

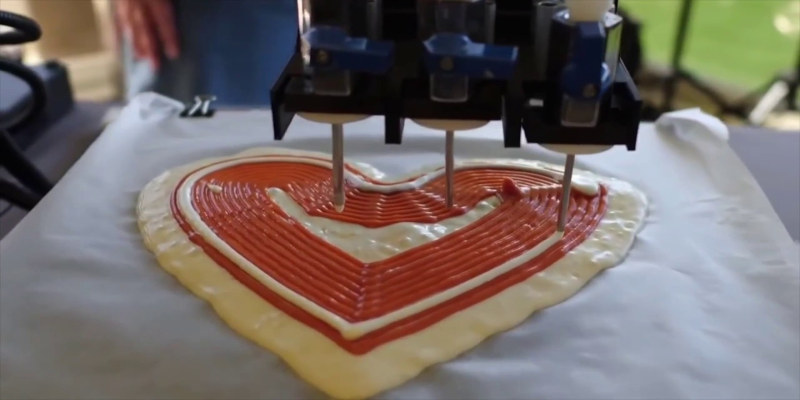

Food, water, shelter, and medicines will be immediately needed by those affected. Most 3D printers cannot immediately print these products, and where they can, they can’t do so at scale.

For example, as an official evacuation point, around 10,000 people took shelter in New Orleans’s Louisiana Superdome the day before Katrina’s arrival. The national guard arrived with 40,000 military MREs (Meal, Ready-to-Eat). Even if a 3D printer could produce one meal every two minutes, it would still take over 1000 hours to print this quantity, by which time the hurricane would have long passed.

Read more: our feature story on 3D printing food.

Ultimately, 3D printing is all but guaranteed to have an expanding role within disaster relief operations, with current projects already proving its effectiveness as a logistical tool. However, with the comparatively low speed and volume of 3D printing, it’s unlikely to ever replace the need for conventional logistics.

3D Printed Emergency Shelter & Housing

3D printing has a proven ability to produce low-cost houses and building infrastructure with a fraction of the cost and speed of conventional construction, prompting continued research into the field. For example, Millebot Inc have developed a large format printer that can operate and be transported within a shipping container.

Despite this, 3D printed is rarely used to house people displaced immediately after a disaster. Instead, they are more often instead used for social programs.

This is because the 3D printers used for construction are often large, heavy, and expensive, forcing them into the same logistical challenges as conventional aid deployments. Additionally, they require constant connection to power lines to operate, something which is frequently damaged in disaster zones.

Additionally, even though 3D printed houses can now be constructed within 24 hours, this is still too slow.

105,000 homes were destroyed within 30 seconds of Haiti’s earthquake, making the most practical way of sheltering the estimated 1.5 million displaced people being the shipping of conventional emergency tents.

As if to compound this, having just seen their homes crumble around them, many Haitians refused to enter buildings being used as temporary hospitals. During an interview, Stephanie Kayden, another Director at the Harvard Humanitarian Initiative, explained that:

“Even though the place where we were working had buildings that were very strong… the people that we were helping were too afraid to go inside them.”

This forced the Initiative to use tents and converted trucks as operating theaters.

Despite limited use in immediate disaster responses, 3D printed housing is still used by NGOs and charities for social programs. for example, the organizations 14Trees and Thinking Huts uses 3D printing to accelerate the building of schools and homes in places where infrastructure or affordable housing is lacking.

On that note, there have been various projects aimed at 3D printing affordable housing for the homeless and vulnerable, however, few have committed to 3D printing quite as much as Austin Texas’s “Community First! Village.”

Community First! Village

Amber Fogarty, President and Chief Goodness Officer of Mobile Loaves & Fishes, the organization behind the village, explains:

“Every single neighbor that calls Community First! Village home pays rent in order to live here. We create micro-enterprise opportunities for our neighbors to earn a dignified income doing things that they love to do.”

And these enterprises are significant too. They have a car servicing business, art house, pottery operation, blacksmithing and woodworking shop, and an organic farm.

In 2018, Mobile Loaves and Fishes announced that they would be significantly expanding the village’s capacity by using 3D printing. Amber Fogerty again explains:

“We have about 230 people living in micro-homes and RVs. On Phase Two, [the 2018 announcement] we will add 300 more homes and introduce something that has never been done before: 3D printing three houses at a time.”

Working with 3D printing company ICON, the first production of houses is already complete, with six houses and a welcome center already printed.

Each home is 400 square feet, and features single bedrooms, bathrooms, living rooms, and porches with sweeping views of the Texas sunset.

Icon deployed its large-format Vulcan II 3D printers for the task and fed them a proprietary mix of concrete to build most of the structures.

Considering that Community First Village eventually aims to house 40% of Austin’s homeless population, the reduced cost and construction speed that ICON’s 3D printed homes offer could make that a reality.

3D Printed Prosthetics

3D printing is already used in the development of some modern prosthetics. However, what is perhaps being missed in these new developments, is 3D printing’s potential to make these limbs more accessible.

For example, New York’s Hospital for Special Surgery say a new prosthetic leg can cost anywhere from $5,000 to $50,000.

Within, Glenn Garrison, the hospital’s director of prosthetics and orthotics also explained that “they’re probably in line with a cost of a car. It can be a pricey thing to work with.”

Read more: our full feature story on 3D printed prosthetics.

The effect is that most of the world’s population simply cannot afford all but the most rudimentary of prosthetics. This is especially true for children, who must regularly have their prosthetics replaced as they grow.

Even nations with free or subsidized health services suffer from long prosthetics waiting lists, and restrictive options when it comes to available models.

What 3D printing offers then, is the opportunity for these individuals to affordably build their own prosthetic limbs.

E-Nable

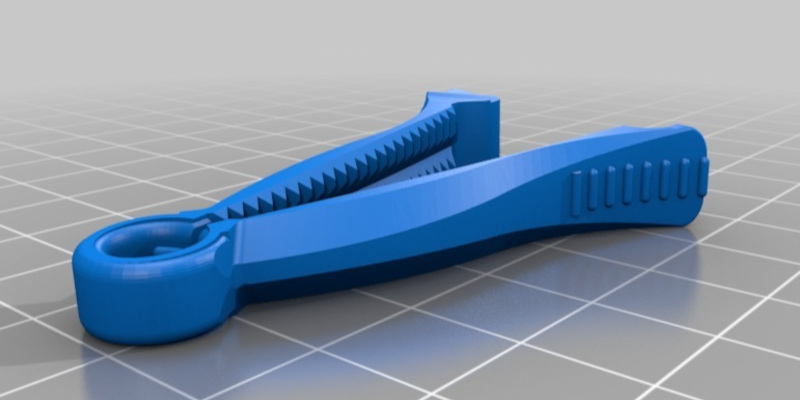

E-Nable is perhaps the most well-known of these 3D printing prosthetic communities. The concept is that volunteers will design prosthetics that can be printed on desktop 3D printers, and then make their designs open-source and available for others to use. The result is that patients looking to print their own prosthetics can simply visit E-Nable and find detailed designs and instructions on how to 3D print their own devices, as well as access to a community of people willing to support them.

In one case, E-Nable’s Yemen-based group, the “Aden Chapter,” began treating victims of the country’s civil war. Abdulla, the Chapter’s founder, explained that:

“The team spent August 2017 printing, redesigning, assembling, and reprinting for the first case… Mossa, our first recipient, 18 years old, lost his left hand by an explosive war remnant. Doctors had to amputate the injured area of the hand rather than proceeding any further medication since the health facilities were crowded and occupied by more sophisticated and serious injuries… He loved the design and gave us valuable feedback.”

E-Nable later reported that “Mossa has been using his new arm to carry objects that are up to 5kg, holding objects and cups and opening bottles. He has also been using this device to write his name!”

Mossa is an interesting case of accessibility. His issue wasn’t the price or availability of prosthetics, but simply the overwhelming pressure of Yemen’s health services. Ultimately, without 3D printing communities like E-Nable, people like him would still likely be on waiting lists.

How key is 3D printing for bettering people’s lives overall?

While that is a difficult question to answer, 3D printing’s continuing increasing adoption in building temporary homes for the disaster-hit — the father of construction 3D printing, Dr Behrokh Khoshnevis, originally came up with the idea when thinking how to help disaster-hit populations — as well as in prosthetics, building low-cost homes, and in humanitarian aid, make it a hopeful piece of the larger puzzle in raising living standards worldwide.

Right now, 3D printing’s impact is comparatively minimal, but with great advances being made, particularly in house-building, there is a lot to be hopeful about with 3D printing’s ability to do good.