3D Print Ghosting & Ringing: All 5 Issues Fixed

At 3DSourced we’ve covered everything 3D printing and 3D since 2017. Our team has interviewed the most innovative 3D printing experts, tested and reviewed more than 20 of the most popular 3D printers and 3D scanners to give our honest recommendations, and written more than 500 3D printing guides over the last 5 years.

Few things are as frustrating as ringing and ghosting – which ruin your print with unsightly lines and circles that affect your print’s finish and make models look cheap and poorly designed.

Much like how you want to avoid layers and lines when painting a wall, you’ll want to avoid ghosting in 3D printing. If you find unwanted lines and rings in your models, then you’ll know just how much of a pain they can be, and how hard they are to look at.

In this article we’ll look at exactly this ‘ghosting’ is, its causes, and how to fix them. So don’t worry, just follow our advice here and you’ll have perfectly smooth prints in no time.

- Ringing and Ghosting in 3D Printing: Causes, Fixes & Prevention Tips

- What Does Ghosting Mean in 3D Printing?

- What Causes Ghosting in 3D Printing?

- How do You Fix Ghosting on a 3D Printer?

- Tighten Your Printer’s Frame

- Be Careful Where You Put Your Printer

- Make Sure Your Build Plate is Secure

- Lower Your Print Speed

- Reduce Jerking

- How to Prevent Ghosting in 3D Printing

Ringing and Ghosting in 3D Printing: Causes, Fixes & Prevention Tips

The main causes of ghosting in 3D prints are:

Here how you can fix ghosting in 3D printing:

- Tighten Your Printer’s Frame

- Be Careful Where You Put Your Printer

- Make Sure Your Build Plate is Secure

- Lower Your Print Speed

- Reduce Jerking

Prevent ghosting in your 3D prints with these techniques:

What Does Ghosting Mean in 3D Printing?

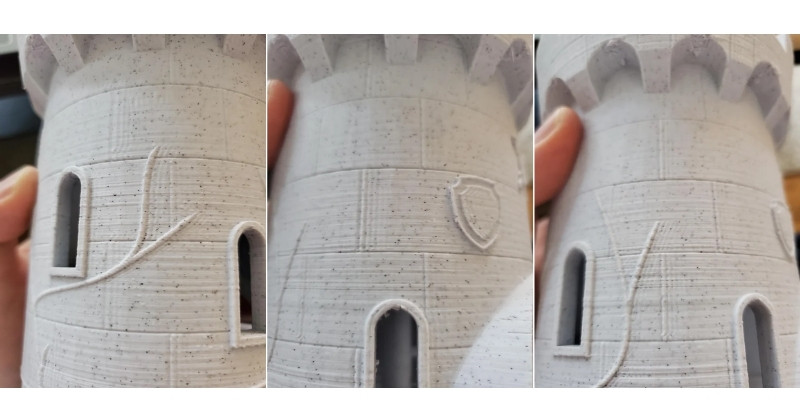

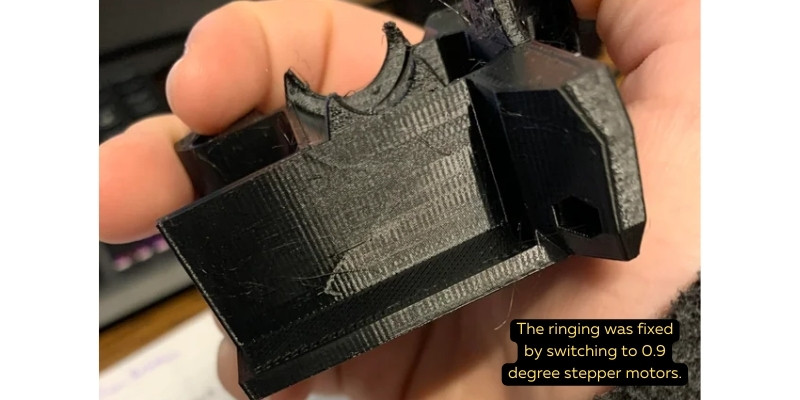

Ghosting, also known as ringing, is a 3D printing issue that creates an unwanted rippling effect on the surface of your print. These ripples and rings affect the quality of the model’s look, often ruining the print’s overall aesthetic.

There are a few reasons for ghosting in 3D printing, and we’re going to look at them here. If you’ve found these ripples on your print, then be sure to look at each issue we’ll discuss to find what could be causing it for you and how to fix them.

What Causes Ghosting in 3D Printing?

The most common cause of ghosting in 3D printing is vibration. If your printer’s frame or build plate is loose or unstable, then the printer will vibrate and shake too much while printing – and filament won’t be evenly dispersed enough to create a smooth surface.

We’ll also cover settings issues that could be causing these unwanted ripples below.

Loose Frame

3D printers are designed to be sturdy and rigid and stay that way while printing. If any part of your printer’s frame is loose, then the printer will vibrate while operational, leading to a ghosting effect.

These vibrations may be difficult to spot with the naked eye, so the problem could be a loose frame even if you don’t seem to notice any movement.

Bad Printer Support

Vibrations are a common problem for 3D printers set on less-than-ideal surfaces. If your 3D printer vibrates at all and is also set on a wobbly surface, then the problem will be exacerbated to the point of ghosting.

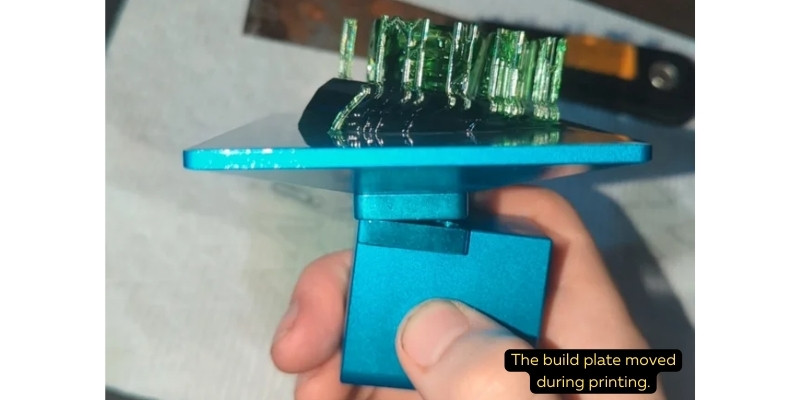

Unstable Build Plate

Build plates are also supposed to stay put while printing. If the plate moves around even slightly while printing, then the filament will be unevenly dispersed, leading to ghosting.

Much like your printer frame, this movement may be indiscernible at a glance. So this could still be your issue even if you don’t seem to notice while your printer is working.

Printing Too Fast

Printing too fast is a common cause of many 3D printer issues. Overly fast printing can make you printer’s nozzle vibrate too much while extruding, shaking filament and distributing it unevenly.

Inefficient Design

A rarer but still notable cause for unwanted vibrations is an inefficient design. If your model requires too many sudden direction changes while printing, the jerkiness of these changes can cause vibrations and lead to unwanted rippling.

This could also be due to acceleration settings. If set too fast, these settings will also cause unnecessary jerking that will print ripples onto your model’s surface.

How do You Fix Ghosting on a 3D Printer?

The key to fixing ghosting issues in 3D printing is to minimize vibrations. You can do this be shoring up your printer’s frame, better securing your build plate, ensuring your printer is on a stable surface, or fixing your acceleration and print speed settings to print more smoothly.

Here are a few ways you can fix ghosting issues in 3D printing:

Tighten Your Printer’s Frame

The main cause for vibrations, and thus ghosting, is loose parts in your 3D printer frame. Simply tightening the screws and rods that connect your printer together will ensure the frame is sturdy and stop it from vibrating too much while printing.

It’s also worth checking to make sure your extruder is fastened tightly, too, as the vibrating problems could also be coming from a loose nozzle.

Be Careful Where You Put Your Printer

If your printer is on an unstable surface then it will worsen your printer’s vibrations. Keeping your 3D printer on an even, stable surface will help reduce these vibrations and lessen the chance of ghosting.

For the best results, keep your printer on a thin layer of soft, shock-absorbing material like a rubber mat, which will help keep your printer steady at its base.

Make Sure Your Build Plate is Secure

Like shoring up your printer’s frame, it’s a good idea to make sure your build surface is attached as well as possible. You may need to replace the springs or supports if they’ve become worn, so be sure to check this regularly.

Lower Your Print Speed

A good rule of thumb is to print slower for higher quality results. Lowering your print speed will help reduce vibrations and will let your extruder layer the filament more evenly.

Printing slower may not also alleviate ghosting issues, but could also leave you with better prints overall. When in doubt, always check the settings recommended by your filament manufacturer and stick to the lower end of the speed scale if you’re running into issues.

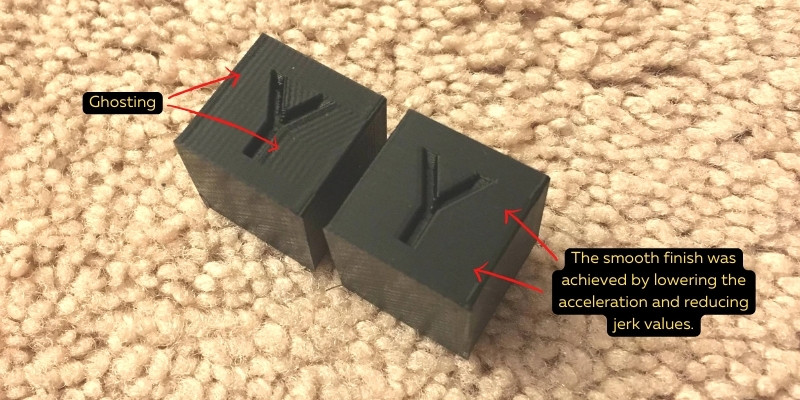

Reduce Jerking

Jerking happens when the extruder needs to change direction quickly to accurately print a model. This can be reduced by altering the starting point of the extruder, or by tweaking your design to have fewer turning points overall.

You may also find that your acceleration settings are too high. Overly fast acceleration will increase jerky movements that lead to a rippling effect if overused. Simply lowering these settings could work wonders in preventing ghosting in your models.

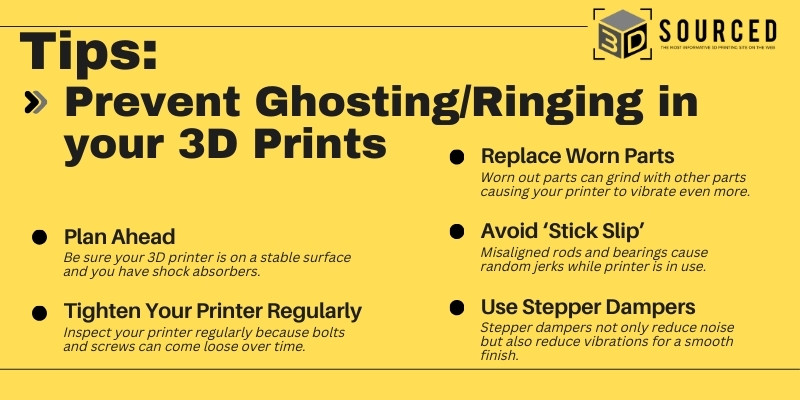

How to Prevent Ghosting in 3D Printing

The best way to solve the issue of 3D printer ghosting and ringing is to prevent the issues entirely. Sitting your 3D printer on a rubber surface, regularly shoring up your frame’s joints, and replacing worn parts where necessary are all great prevention methods.

Strong vibrations will not only cause ghosting and ringing in your prints, but will also damage your printer over time. Parts and pieces that rub together unnecessarily and wear down faster, which can be expensive to replace or even become dangerously unstable in the long run.

With that in mind, here are some ways you can prevent ghosting in 3D printing and even protect your 3D printer by reducing vibrations.

Plan Ahead

We’ve already discussed keeping your printer on a shock-absorbing surface, but it’s better to do that before you notice a problem or at least before it gets too bad.

Making sure your 3D printer is on a stable surface like a sturdy desk is a good start, and using a rubber mat for shock absorption will help greatly in keeping your printer still while it works.

Tighten Your Printer Regularly

Another great way to reduce vibrations is to get into the habit of giving your machine a regular once-over. Tightening any bolts and screws that have become loose over time will make sure your printer stays as still as possible while it prints and helps prevent ghosting entirely.

The frequency with which you should perform these checks depends on how often you use your 3D printer. In general, it’s good to tighten everything up every 5-10 prints to keep things running smoothly.

Replace Worn Parts

Rods and beams that have become worn, rusted, or otherwise damaged over time will grind together and vibrate your printer too much, leading to ghosting.

Checking these parts for wear and tear will help you catch these problems early, and it’s a good idea to replace them whenever necessary. Sometimes, you may just need to wipe down these parts or free them from debris that may have been caught, causing them to move against each other with too much friction and vibrate too much.

If you find these parts are becoming damaged far too quickly or often, then you may need to check with your manufacturer to make sure there are no underlying faults in the hardware.

Avoid ‘Stick Slip’

If your printer is halting or stuttering, or even just making an unpleasant grinding noise, then there’s a chance that your rods and bearings are misaligned. This causes random jerkiness that stutters and shifts while printing instead of being a smooth motion.

If you assembled your printer yourself and notice these faults almost immediately, then you may need to dis- and re-assemble your printer, taking care that everything is aligned correctly.

If it’s a relatively new problem, then some of your 3D printer parts may have become misshapen or bent, and will need to be replaced.

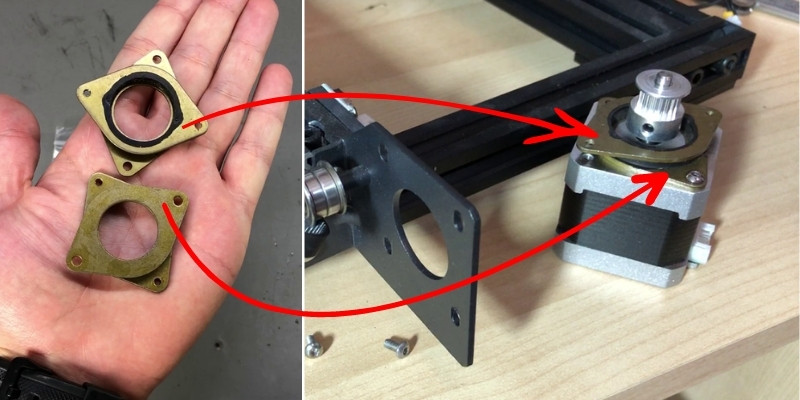

Use Stepper Dampers

Stepper dampers are multi-purpose shock absorbers used to reduce resonance in moving machinery. They’re commonly seen in speaker systems to make sure the vibrations don’t affect the sound quality or damage the inner workings of the machine.

These dampers effectively offer a rubber buffer between moving parts that doesn’t actively affect their function by reducing movement.

If you’ve ever had a problem with your 3D printer being too loud, then you’ve likely come across stepper dampers before, as they reduce the noise made from the uncovered motor. But they serve a secondary purpose in reducing vibrations and will keep your printer running steadily as it works to help create smoother, ripple-free models.

Related posts: