How to Use 3D Printer Cleaning Filament (Full Guide)

At 3DSourced we’ve covered everything 3D printing and 3D since 2017. Our team has interviewed the most innovative 3D printing experts, tested and reviewed more than 20 of the most popular 3D printers and 3D scanners to give our honest recommendations, and written more than 500 3D printing guides over the last 5 years.

You don’t have to have used a 3D printer for long to realize that regular maintenance is a necessary evil.

The better you look after your printer, the less time you’ll spend scratching your head over it.

One of my most common frustrations is coming back to my machine printing in ‘thin air’ because it stopped extruding part way through the print.

In some instances, it’s not even a blockage, but an otherwise perfect print finishing with little specks of the previous color filament embedded in it.

The extruder and nozzle components of your are arguably the most sensitive parts to your printer, and the hardest to keep in top condition – but it’s crucial maintenance if you’re aiming for perfect 3D prints.

How not to clean your nozzle

And that’s where cleaning filament comes in. Use it proactively and it’s the best preventative measure, yet it’ll also help to unblock all but a fully clogged nozzle.

In this article, we’re going to cover everything you need to know to use cleaning filament effectively and discuss how it stacks up against other cleaning methods like the ‘cold pull’ technique.

P.S If you’ve currently got a fully blocked nozzle, you can read our full guide to unclogging your nozzle here.

How Does Cleaning Filament Work?

You’re likely skeptical that cleaning filament is a bit of a gimmick. Or just as likely, you’re not convinced you even need it.

Never had a blockage before? I don’t believe you It can happen to anyone at any time.

Some think cleaning filament as just made from Nylon or HDPE filament – which is the material of choice for the cold pull method. It isn’t by the way (and you don’t use the cold pull method with cleaning filament).

Or perhaps it’s just a cheap, highly abrasive material that strips everything out? And presumably erodes the inside of your nozzle over time…

Again, no. It’s actually (we can only speak for ours, of course) a non-abrasive industrial-grade compound for purging hard-stuck chemical residues out of injection molding machines.

We’ve sourced the best we could find, modified it for a larger range of operating temperatures, and extruded it into 3D printer-friendly filament form.

Why Is Cleaning Filament Better Than Other Methods?

First on the left, towards a cleaner nozzle on the right. You can see how this can easily take 5-6 ‘pulls’

The well-known ‘atomic method’ or ‘cold pull’ has long been the method of choice to clean out your nozzle.

Often done after you’ve experienced a full or partial blockage, the general method goes like this:

- Heat up your nozzle to around 250°C and insert Nylon filament as far as it will go, then cool the nozzle back down to about 30°C while maintaining the pressure.

- Once cool, quickly pull the Nylon out. Usually takes a good hard yank (you may need one hand on your printer to prevent it from being pulled off the desk).

- Do this procedure 3-5 times or until the end of the filament you’re pulling out is clear and has a well-defined tip (indicating a clear and residue-free nozzle).

In our opinion, this process is a little bit brutal. The whole process puts a lot of strain on some relatively delicate parts in your machine.

It also takes time to heat and cool your nozzle each time. You don’t want to leave the material hot in the nozzle for too long either; it definitely won’t help your situation).

The other option is if the cold pull method won’t work, you’ll likely need to insert a very thin drill bit or hypodermic needle up there. You’ll want to use the same size as the nozzle.

For 0.4mm nozzles, this is just about possible, but if you’re printing with 0.2mm nozzles or small – you’ll probably be best off just replacing it.

The risk here, apart from the obvious dangers of using very small, thin needles (we don’t recommend it, for the record) is that they can snap off inside the nozzle.

You’ll notice neither of these methods is really foolproof, or that user-friendly. Luckily, there’s a better way that’s fairly new on the scene.

3D Nozzle cleaning filament takes far less time to clean out your nozzle. Often in as little as 30 seconds, and you don’t need to do anything out of the ordinary, except changing filament. Which you should be pretty comfortable with by now…

Disadvantages of Using Cleaning Filament

This wouldn’t be a fair review without telling you what you can’t use it for, and why it’s not for everyone.

- You can’t unblock a fully clogged nozzle with it. You need to have at least some flow rate to work. That’s why it’s always best to have and use nozzle cleaner filament before you need it.

As long as some filament comes through with a small amount of force, you should be able to unclog your nozzle. And we promise we won’t stand back, arms folded saying “told you so” the whole time…

- It’s expensive. Well, it isn’t. But at first glance. You see, you really don’t need much. About 0.5 to 1 gram per use, maximum. Luckily you don’t need to buy a whole KG spool of it then (if you did, ours would be £360/KG).

For around £18 you’ll get 50 grams, which will get you a solid 70-100 nozzle purges. That’s just 20p per clean, in 30 seconds. Compared to 20 minutes yanking your 3D printer around for each clean, well – it’s a no-brainer.

What to Consider When Buying Cleaning Filament

Make sure you know what you’re getting. Some cleaner filaments could just be re-branded cheaper materials that don’t perform as advertised. Make sure you read the reviews, and factor in the price.

There may be cheaper ones on the market, but it’s worth weighing up – you may need more grams per clean if they’re not as effective, so it could end up being more expensive overall.

Other known brands we’re aware of are Lulzbot and eSun cleaning filament, so it may be worth doing your own testing.

Reviews are usually a pretty good indicator that it does as advertised. As for where to get it, you can find a few popular brands on Amazon.

How To Use Cleaning Filament

If you’ve bought some already and you’re left wondering what to do with this un-printable filament – or you’re just wanting to read up on cleaning filament instructions before you begin, here we explain what you should and shouldn’t be doing with your new one-stop 3D printer cleaning kit.

For most machines, there’s no need to cut the cleaning material, just load and unload like a regular filament.

For other machines or if you have an under extruding partial blockage, you may wish to unplug the Bowden tube to manually push the Floss filament through the nozzle.

When printing with the same material:

- Printing with one material like PLA, all the time? How often you need to use your cleaner filament will depend on how often you print, and the quality of filament that you use. Poor quality or cooked/burned filament can leave residue in your nozzle. Even PLA can solidify in the nozzle over time, so we advise flushing it through at least every 200 – 400 printing hours.

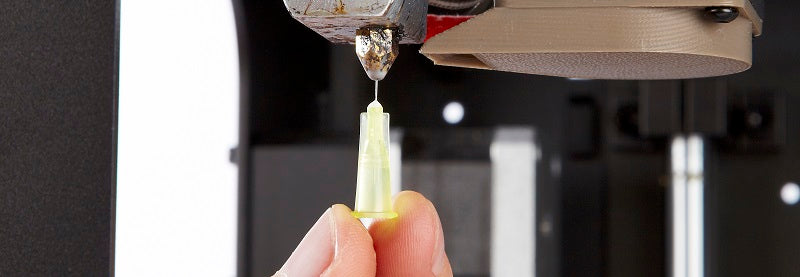

- Depending on your printer design, there are a few ways to use cleaning filament. In most instances, simply unload the previous filament and load your cleaner filament as you would any other filament.

- Keep the printing temperature the same as your printing filament and begin to extrude the new cleaner material into thin air (don’t try to print with it!). Many printers will extrude a set amount as part of the loading process anyway. Keep extruding until you cannot see residue of the previous material, or contamination specks. Once it runs clear, simply unload and reload with your printing filament. No need to try a cold pull (although you can if you’re still not convinced it worked).

When printing with different materials:

- Always run the cleaner filament through at the last printing temperature. So if you were using PLA, and you’re changing materials to ABS, run the cleaner through at around 200C, not 230C. Likewise, if your last material was Nylon and you’re changing down to PETG, you’d run the cleaner through at around 260C. Our Floss cleaning filament has a temperature range of 200-280C+

- As before, run enough filament through until you’re sure you cannot see any specks or residue. Then just unload and proceed as normal with your new material, ensuring the nozzle is at the correct temperature for the new material before you load it.

And that’s it, that simple. You may need to manually feed it if your nozzle is partially blocked to get some to feed through, just to apply a little extra pressure.

Although don’t force it, if your nozzle is completely blocked unfortunately you’ll just have to use one of the previously mentioned unblocking methods.