The 10 Coolest DIY 3D Printable Robotic Arm Projects

At 3DSourced we’ve covered everything 3D printing and 3D since 2017. Our team has interviewed the most innovative 3D printing experts, tested and reviewed more than 20 of the most popular 3D printers and 3D scanners to give our honest recommendations, and written more than 500 3D printing guides over the last 5 years.

Exploring 3D printing robotics is easier and cheaper than ever before, so there is no excuse not to give it a go. Having said that, it takes a lot of time and practice to become an expert. While you might not be ready to build a Terminator in your bedroom, 3D printing robotic arms is an excellent starting point for enthusiasts.

Easily programmable, with fewer moving parts and simple functions, robotic arms are an accessible entry-level sector in 3D printing robotics.

That being said, the current state of print-at-home robotics is nothing close to I-Robot. Robotic arms are little more than controllable or programmable pick-and-place tools right now.

But, there is plenty of cutting-edge technology here to whet anyone’s appetite. And many are open source, so anyone can download the files and have a go at printing themselves. They are a fantastic tool for anyone interested in robotics to teach themselves about robotics, and impress your friends.

1. LittleArm- The Entry Level

As the name suggests, LittleArm is the smallest, most simplistic, and easiest to print of all the robotic arms on this list. But that does not make it totally useless. Crucially, it is that simplicity that makes it so useful.

Everybody has to start somewhere, especially in 3D printing, and LittleArm is the ideal entry level project to get you hooked on 3D printed robotics. With only 3 degrees of freedom, meaning 3 points of movement on the arm, it is very easy to understand, both when 3D printing and programming.

With little more than a 2C motor and a roll of PLA filament, you can construct the 31 parts needed to build this rugged and flexible arm that can be assembled in less than an hour. Just like David against Goliath, don’t write off the little guy just yet.

2. EEZYbotARM MK3: The Second Base

The EEZYbotARM is an ever-evolving 3D printing project that is currently on its third form. Developed by Carlo Franciscone, an engineer from the Novara, Italy, the EEZYbotARM is a slight step up in complexity from LittleArm.

The main enhancement is its 4 directions of freedom, with a rotating base, 2-finger gripper, and a pivot in the arm that allows it to bend. While it doesn’t have the strength to handle a significant payload, it’s definitely a project worth using as an experiment.

The MK3’s design is very similar to its original. The MK2 was created to be a little larger and stronger than its predecessor, but the MK3 returns to the smaller design, with a focus on cheaper motors and construction costs. It was made using ABS, but PLA is also very possible.

If you are looking to try something a little more physically impressive, the MK2 is the clear choice. But when focusing on the accessibility of 3D printable robotic arms, the EEZYbotARM MK3 is your best bet.

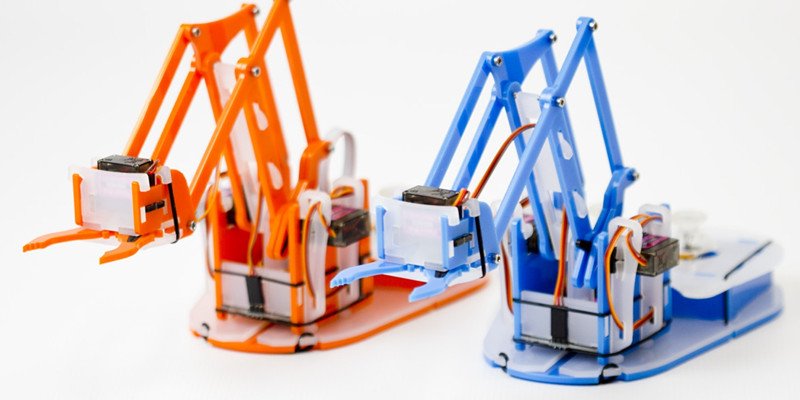

3. MeArm: The Everyman 3D Printed Robotic Arm

Hailing from United Kingdom, MeArm is the 3D printed robotic arm project that can cater to anyone. The kits are available to buy on Amazon if you didn’t feel like printing it yourself, but you can also access all the open-source files you need. You can even use a laser cutter if you don’t have a 3D printer to hand.

The MeArm is intended to be easy and fun, with an array of different color schemes. The parts are deliberately simple and easy to fit together. And on top of all that, it comes with a healthy choice of control options for whatever tools you have available.

Want to control the arm using joysticks? MeArm has kits for Arduino and Raspberry Pi, as well as many more. Want to pre-program the arm? There’s a BBC micro:bit kit compatible with Microsoft Make Code. Do you have your own controller you prefer using? You can just get a MeArm without any add-ons. Whatever you need, they have you covered.

4. Instructables 3D Printed Robot Arm

This is where the scale and intricacy start to rise. The Instructables Workshop has featured lots of amazing 3D printing projects over the years, with a library big enough to have something for everyone. And their 3D printed robot arm is as grand as it is cool.

With circuitry that can be purchased from any good electronics store or wholesaler, the 3D printed arm is a great example of progression for hobbyists or professionals looking to hone their skills. A full list of materials and components, as well as a useful step-by-step guide, can be found on their website.

Its compact control base makes operation incredibly easy, and all the parts snap together for handy assembly that is surprising fast for an arm of this size. Once you get the basics right, this is the best next step.

5. Kauda Robotic Arm

While a lot of the more advanced 3D printing robotics projects are designed for educational purposes, the Kauda robotic arm is the most widely accessible. Its smaller size means that it is a handy teaching tool for computing students of all ages and abilities.

While Giovanni Lerda’s bulky and more classic design isn’t to everyone’s aesthetic taste, it makes visually understanding the mechanism much easier, vital for younger students. And its small, desktop scale make it an ideal and affordable tool for classrooms across the world.

Computing is fast becoming one of the most important subjects at schools as technology evolves at breakneck pace. Children will increasingly become reliant on education into programming. Few robotics projects on the market today can rival Kauda for ease of access, and it is all made possible by 3D printing.

6. How To Mechatronics’ Robotic Arm

A big way to enhance these 3D printed robotic arm projects is to integrate technology that everyone has access to. With that in mind, online engineering site How To Mechatronics have created a controllable 3D printed robotic arm that is operated by a self-designed smartphone app.

The custom android app can be connected via Bluetooth to a node built into the arm, and the user can control the robot using a series of sliders. While the app is not available to download from any store, they do break down how it works and encourage others to recreate its functions and features.

With 3 pivot points, the arm itself is extremely flexible and responsive, making the arm more dexterous and precise. This gives the arm a wider range of industrial applications when the technology becomes more ubiquitous.

And the guide on how to make it is very detailed, walking you through every step carefully. Combining the advanced technology of 3D printed robots with the everyday technology we all have at our disposal is a significant step forward for the industry.

7. Zortrax 3D Printed Robotic Arm

Polish manufacturer Zortrax has developed a 3D printed robotic design with perhaps one of the sleekest and most attractive designs around. It is one to drop anyone’s jaw. The concept art produced looks beautiful, and the files to recreate the design are available to all.

But the Zoftrax 3D printed robotic arm isn’t just a pretty face. It also has a range of useful applications. The design’s 5 degrees of freedom make it as flexible as the best on the market, and the hand at the end is designed to be replaceable with tools like screwdrivers, drills, wrenches, or electromagnets. This makes it a valuable tool for mechanics and construction companies.

The boundless possibilities of this arm through its range of attachable tools make it a very exciting project, and one to keep an eye on as the developers no doubt work on its evolution.

8. Roboteurs RBX1

Technology companies are always looking to go that one step further with their projects. One more turbocharger, one more processor, one more centimeter. It’s no surprise then to see the Roboteurs RBX1, the first 3D printed 6-axis robotic arm.

At this point, there are few practical applications of an arm this complex, other than impressing yourself and anyone else who is interested. But while it may be on the sillier end of the spectrum in that regard, there is a lot here to be excited about.

Roboteurs sell their construction kits online for a modest price considering the level of technology involved. It is one of the only 3D printable robotic arms that require no external machined components, with everything needed provided in the kit.

It is also extremely easy to operate. It is compatible with the most common operating software, and photos provided on their website even feature an Xbox controller! If a 12-year-old Fortnite player could handle this machine, so can you.

9. Haddington Dynamics Robotic Arm

Based in Las Vegas, Nevada, Haddington Dynamics have developed the Mark Henry of 3D printable robot arms. Previous attempts to create a robot arm, affectionately named ‘Dexter,’ using PLA were too weak for HD’s liking. However, after one customer’s advice, and in collaboration with NASA, they began using a Markforged printer.

This allowed them to redesign the robot and begin using carbon fiber, reducing the number of parts from 800 to just 70. The result was a much larger and more robust design with fewer joining points between components that drastically increased its payload weight. The current iteration has a reach of 770mm, and can lift objects as heavy as 3 kilograms.

That might not sound like a lot in the grand scheme of things, but in the world of 3D printed robotic arms, that much weight would put Atlas to shame.

10. BCN3D MOVEO- The King

The BCN3D MOVEO is one of the best and most well-rounded 3D printed robotic arms projects around. The biggest reason is that it incorporates all of the features we’ve mentioned here into one machine.

Developed at the Departament d’Ensenyament from the Generalitat de Catalunya in Spain, it was originally designed with education in mind, currently used in 15 different institutes around Catalonia as an educational tool. It has a flexible 5-axis construction with an attractive design, and while it is not capable of extreme weightlifting, it is comparable in function with any of its similar peers.

This pick-and-place device is among the most advanced all-round machines in the industry, with the express purpose of being accessible to anyone. It’ll take a lot of expertise to make your own, but there are few more promising devices around for robotics enthusiasts.

Other fun 3D printing project articles: