RepRap Founder Dr Adrian Bowyer on Creating the First RepRap, Open Source & Future of 3D Printing

At 3DSourced we’ve covered everything 3D printing and 3D since 2017. Our team has interviewed the most innovative 3D printing experts, tested and reviewed more than 20 of the most popular 3D printers and 3D scanners to give our honest recommendations, and written more than 500 3D printing guides over the last 5 years.

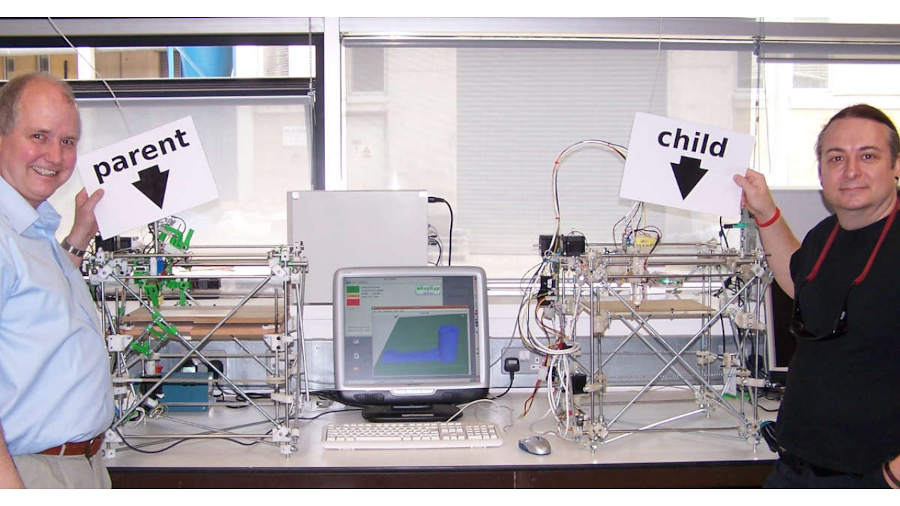

Dr Adrian Bowyer is known as the originator of the RepRap movement that spearheaded the low cost 3D printer advances that we enjoy today. Along with university help, as well as collaborators across the globe — that never met, or even spoke over the phone! — this motley crew of genius creatives developed the first partially self-replicating machines, the embryo for potential future fully self-replicating machines of the future.

We were fortunate to spend over an hour speaking with Dr Bowyer and hear his thoughts on how the RepRap movement came to be, the struggles and obstacles the group overcame along the way, his thoughts on the future of open source 3D printers, how they invented a lot of the technology we take for granted in our 3D printer kits today, and much more.

Our questions are in bold, Dr Bowyer’s answers in quotes.

Before your first declaration of the RepRap movement in February 2004, how long had you had the idea for RepRap?

“I’d been interested in self-reproducing machines since I was a child, I don’t really know where that originated — nearly 70 years ago. That was a constant background interest. Though it wasn’t a research activity, I had not done any research into self-replicating machines.

“But, the real genesis of RepRap was when the British government gave my university a very large equipment grant, and rather foolishly perhaps the university gave it to me to spend! And I decided to buy a couple of 3D printers.

“I had known about the tech for decades but had never worked in it or done anything with it. The machines arrived, and suddenly I realised that for the first time really, we had a machine that was sufficiently versatile, in the geometry that it could manufacture, that it stood a significant chance of making a good fraction of its own parts, if not all of them.”

And in 2004, in your eyes what was the state of 3D printing?

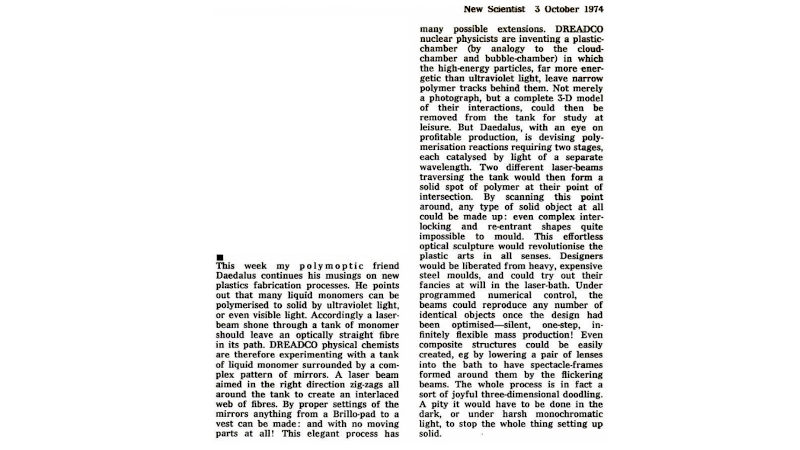

“It was a mature technology that had been going for 20, 25 years. The idea first appeared as a joke in 1974 by the New Scientist column by David Jones who used to write a column under the name Daedalus.

“He basically invented stereolithography with a laser, and invented it as a joke. A joke invention, but this one turned out to work!

“They [3D printers] were fabulously expensive: the cheapest one when I started the RepRap project cost around £40,000, and in fact that was one of the ones we bought at the university. When I looked at how it worked, it seemed it would be possible to make such a machine at a considerably reduced price, but my primary aim was to produce a machine that could produce most of its parts. And so, that was the way the project went.

“Some of the machines we used cost a quarter of a million pounds, and I felt that some of them didn’t need to cost that much. And more importantly — they didn’t copy themselves; so I decided to make one that did.”

Everything points back to a Bath University £20,000 grant to kickstart the project. What did it require to get that, and did the people you pitched it to understand the RepRap idea at first?

“I was in a very happy position through no effort of my own, that the EPSRC had given Bath University a block grant that they could then divide up between [the university’s] researchers.

“So I didn’t have to pitch it to anyone outside of the university. I basically had to put together a proposal for a group of academic colleagues in the uni itself. It was the smallest grant I’d ever asked for.

“I’d spent decades doing fairly large projects, costing a quarter of a million or half a million pounds. Those projects had almost all been successful, and so the fact I was asking for 20 grand didn’t raise too many eyebrows because I had had done things in the past for much more money, and I hadn’t lost the money!

“But, I wanted to pitch it at a price that was half the cost of the single cheapest machine you could buy at the time, because I wanted to show you could do the whole project for less than the cost of the machine.

“And I worked out that would be roughly what it would take to buy equipment and materials and so on. A slight cheat is that I also had a research assistant working on the project [Ed Sells, a key part of early-stage RepRap progress], and his living expenses were paid for.”

Did the people you pitched RepRap to understand it instantly, or did they not see the vision immediately?

“They got the hang of it. I had been working for some years on the overlap between engineering and biology, the idea of biomimetics — which is taking things out of natural systems and putting them into engineering — and had done quite a bit of work in that area anyway, and the obvious parallels to RepRap is that it’s a self-producing machine, and biology is the study of thing that copy themselves.

“So, it was an area in which I was working, so I didn’t have very much work to do to persuade my colleagues that it might be a good idea. And when I explained it, everybody pretty much thought it would work — in principle. They couldn’t see any major impediments. But, in fact that’s not quite how it happened! It was they who persuaded me to do it!

“I mentioned that I wrote this paper on the idea, and I also mentioned that I was busy doing other projects, some of them for significantly more funds than I asked for for RepRap, so when I wrote [the paper] I didn’t actually think I would do it myself — I thought well, I’ll put this out there and if someone takes it up it might be interesting if they get it to work.

“And as soon as I’d done that, several of my colleagues came and knocked on my door and said well why don’t you do it. So, it was actually at their prompting that I applied for the money, not my desire to do what turned out to be my own project.”

And without the money, was the project dead in the water?

“It would have been slower without the money. If I hadn’t got the money, and hadn’t got the research student, then I would have probably run it as a project for undergraduate students, which basically as an academic one has almost complete freedom, so it would have been developed in dribs and drabs.

“It would have slowed it down, it wouldn’t have stopped it completely. The money let us devote one person full time and me part time to doing the thing.”

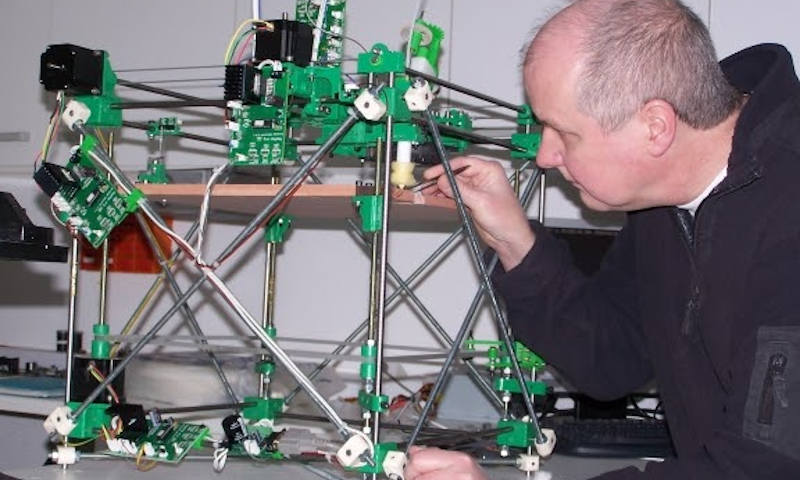

“He [Ed Sells] basically designed the first machine. He would design a bit, and we would have a meeting once a week and go through the current stage of the design, and change bits, try bits out, try things out, build parts of it, build parts of it experimentally, and that sort of thing.

“By this point, around 2005/6, not only had the project been funded but I also put out a press release saying what the project intended to do, because it seemed potentially at least, it seemed a pretty game-changing project, for all sorts of industries and people, and I had a certain moral duty to tell people what I intended to do. It got picked up by the NY Times, BBC, CBC, and that publicity brought new people on board, and they saw an open source project they thought was interesting. So people in New Zealand [Vik Olliver], and the United States, were trying bits out for the machine, of those only Ed and I were being paid.”

[Ed Sells later became achieved a PhD for his work on the project.]

“[Vik Olliver, from New Zealand] was involved long before I met him, in that for years we only communicated electronically, had never seen or held a voice conversation — no Zoom at the time — so it was a bunch of people from all over the world talking by email. I subsequently met Vik, he has family over here.”

In early posts in the RepRap diary, Vik posts about a circular turnstile that would rotate when printing — a Polar 3D printer. What happened to this?

“In principle it worked, but the difficulty is when you get to the outside of the circle, the angular resolution you need in order to get an accurate print is very fine indeed, and we didn’t at the time have the ability to turn the turntable sufficiently precisely that we could make the exterior rim of it rotate by less than a millimetre. In principle it was a good idea and we could probably have printed well in the middle of the turntable, but couldn’t use the whole area given the electronics and the stepper motors we had at the time — and were developing the Cartesian machine in parallel anyway.

“It was completely disorganised [their organization style], I didn’t particularly want to direct it in any orientation at all, we just said if someone has an idea, go away and try it out and see if it works. Ed and I were a little more directedfew because beyond the project my concern was that he had a good research project for his PhD. So when we discussed things it wasn’t only with the aim with RepRap in mind, but also making sure he had a decent bit of research. Someone would come up with an idea and we’d say yeah! Why not! And see if it worked.”

As patent holders at the time, what did Stratasys think about what you were doing?

“As far as the state of the machines is concerned, I’ve subsequently seen what goes on inside one and it’s pretty much the same as the way most RepRaps work, unsurprisingly.

“We deliberately never took it [the Stratasys 3D printer they bought at the university] apart for two reasons: one, so we couldn’t be accused of copying it — and nobody ever did from Stratasys or anyone else — and two, because we didn’t want to constrain ourselves with what they had established.

“For example, the Stratasys machine printed on a bed made of rigid foam, because then it could actually inject the first layer of plastic into the foam and form a very solid base. We decided not to do that, we decided just to try and print on a flat plate instead. You could see that as soon as you used it, without taking it apart.

“We never had any problem with Stratasys complaining about what we were doing, there was only one thing that happened: we got a letter, very nice and very polite, very conciliatory, from one of their legal people saying they had a trademark on the term FDM and could we please not use it, so immediately I invented an equivalent term, which was FFF and we just edited everything on the site to that instead. That’s the only time they tried to interfere or anything else with the project. They never complained we were infringing upon their patent, which we weren’t of course [research projects in Europe can research a patented technology for the purpose of improving it without any kind of patent infringement], and we weren’t selling any machines.

“Once the patent expired in 2009, of course the project was free to do whatever it liked. Coincidentally, that was just a few months after we got the first printer working. It all came together fairly nicely in that regard.”

So you purposefully didn’t look inside or take the machine apart because you didn’t want to influence your own research, to see whether you could come up with an independently better answer?

“Yes. We wanted to make something people could make in their garage, where neither [injection molding or machining] were available. We wanted to make sure it gained its accuracy by virtue of clever design, rather than precision in the making of the components.”

Before you saw any results, did you feel like the work you were doing at the time was important, groundbreaking, or culturally important?

“I was rather more detached than that. It has always been the case that the primary reason I ran the project was to see whether it would be made to work, not trying to drive or force it forward or to work — I’m more driven by curiosity than ambition [Dr Bowyer laughs]. Well, completely.

“I honestly didn’t know if it was going to succeed. I was fairly sure we could make it work and that it would succeed technically. But I had no idea if it would make a big influence on the world or not. And so given that I had no idea, i just awarded the two possibilities 50%, either it would sink without trace, or it would take over the world, it was simply a coin toss.

“Until people started making machines, that was my position. When others making companies based on it, I realised perhaps it was going to do something.”

What did it feel like when the first RepRap (in September 2006) printed a part of itself? Did you think before it worked it was likely to work, and how reliable was it then?

“It wasn’t very reliable then! And I didn’t know beforehand because that was actually done by Vik Olliver on the other side of the world! In fact, I didn’t know he was going to try and do that before he did, he did and then put up a blog post and that’s how I learned about it.

“I thought waheyy, it worked!” [We joke Vik jumped the gun on him.] “No, because there’s no reason why we should have done it any more quickly than anyone else involved!”

What did you feel when that happened?

“It was the first indication physically that what had then had just been in my mind — it turned a hypothesis into a theory if you like. It was something with some substance behind it, and that substance was a literal physical object.”

And do you think now it’s the most important project of your career?

“To me, possibly. Though much earlier in my career I completed an algorithm for computing Voronoi diagrams that’s probably more widely used than even RepRap machines.

“But of all the research I did — and I enjoyed all the projects I ever did — RepRap was certainly the most fun to me. It was interesting because it was so social, it involved so many people interacting — and arguing! — though largely in amicable terms with each other in how to proceed.

“But that aspect of it was something that made it really quite enjoyable. And once we could see it was going to work and that it was going out into the world, of course there’s some satisfaction in that, and now pretty much every FFF 3D printer in the world, with one or two exceptions, is to a certain extent based on what we did.”

And when you were in the design stage, did you envision something that would be in everyone’s house? What was your idea or dream realization at the time?

“I thought that ultimately the number of machines in private hands would probably be the same as the number of paper printers people have now, whatever percentage that is. That’s the sort of order I’d expect. There had been a number of research projects that showed it makes economic sense to have one of these machines, even if the number of machines you have is quite small.

“The analogy I draw is with a washing machine; everyone in the developed world has one, and 95% of the time it sits there doing absolutely nothing, the other 5% it washes your clothes doing very useful things, and I suspect 3D printers will be like that: you have it in the corner, and only use it when something breaks or you need something new.”

Studies have shown that 3D printers already represent a good return on investment, yet over 90% of these households don’t own a 3D printer. I think it’s an intimidation, information problem. How, as the inventor of these, would you get past this?

“Non-technical people criticise paper printers because they jam and break, and these barriers are not a problem for engineers because they know how to fix things and so on.

“The real barrier I think is that, fortunately perhaps, because it would be unfortunate perhaps if the reverse were true, is that not everyone is an engineer, and you do need some technical ability and grasp for it. They’re getting simpler with the user interfaces all the time and better in that regard, but nonetheless you can’t use them without some understanding of what’s going on. It’s not like getting into a car and driving away without knowing anything about how an internal combustion engine or electricp motor works.”

There’s a gap of around two years between the first 3D printed part, and the RepRap 1.0 Darwin printing 50% of its parts. What happened in between that time was most noteworthy?

“Mostly, time was taking up designing once we got the hang of the technology. Those two years were basically writing software and doing mechanical design. There weren’t that many milestones: it was climbing a shallow hill as opposed to suddenly jumping up a big step. We got the tech sort of working, the first printed part, and then we did a lot more basic engineering creation and that was a continuous process.”

What were the biggest difficulties and hurdles to jump over that causes the most drama and difficulty at the time?

“The Cartesian movement of the machine was not difficult to organise, it worked almost from the beginning, and we had extrusion heads that worked. But we initially started by trying to make them as simple as possible which meant driving them with DC motors rather than stepper motors. So they were never wonderfully accurate because the speed they extruded tended to vary slightly even if you were precise, so there we made a decision to try to construct a part of the machine using tech that was going to be very cheap, which ended up being the wrong decision.

“When we came back to making new designs for the extruder heads, we used stepper motors which then worked much better as we could meter the amount coming out of the nozzle. This helped us make the machines work a lot better than the first ones did.”

“[The software] had teething problems, but of the sort you always get when you write software. But three or four of us were working on it and it came together, obviously with bugs but those got fixed.

“And previous research on CAD systems meant I had good idea of how to deal with an STL file.”

So you were pretty well placed based on previous experience to make this work?

“Pretty well, but not uniquely. Thousands of engineers could have done it, they just needed to be good at computing, mechanics and engineering.”

Was there ever a conflict about whether to make it open source, or closed?

“I made the decision before I told anyone else about the project, literally within some minutes of having the idea. It was two-stage decision: I had the idea and then felt it was powerful to release this to the world, and how to make sure this doesn’t cause a great gap in inequity in people who have it and who don’t — and the only way to do that was to give it to everybody.

“This was perhaps an uncharacteristically noble thought on my part! [Dr Bowyer laughs]”

“But if it copies itself, you’ve got to make it open source anyway, as if you don’t, you’ll be forever trying to stop people doing what it was designed to do, and I’ve got better things to do with my time! The whole idea of self-copying forces you to make it open source.

“Some people do things like patenting seeds, which are also self reproducing machines, but they spend an awful lot on things like lawyers — which is a dull and uninteresting thing to do.”

Do you ever wonder what would have happened if you had made it closed source and monetized it?

“No, I never really thought about that. I suspect it would have made a lot of legal trouble for the [Bath] University. One of the things I did when I decided to make it open source was go to the University’s IP department and said I had the research project, and they looked at me a bit wistfully and thought, oh can’t we make money out of it? — but given the thing about academic freedom is that every academic is free to publish their own work in any way they choose, and open source is a way of publication, there wasn’t much they could do.

“They didn’t try to stop it either — they were more amused than anything else — but they couldn’t have done anything anyway.

“My wife and I were some of the financial founders of Makerbot. When Makerbot started, one of the founding members was Zach Smith, one of the founders of the RepRap project. He invited other guys in New York, and my wife and me to put up the original funds.

“We chipped in some money, and of course when they sold the company that had quite grown. We did well out of that — it’s always nice to get a big cheque!”

What’s your opinions on the companies that rather than being completely open source, switched over to closed source, like Makerbot?

“I wasn’t too bothered about it. I wrote a little article at the time saying that I personally disapproved of what they’d done, but I’m not going to do anything about it.

“But of course it comes back to self replication. If you have a closed source self-replicating machine, all things being equal versus open source, it’s obvious which is going to be most successful in Darwinian terms. In biological terms what you’re basically saying is that you’re going to make this sterile. And so it didn’t bother me unduly.

On 23rd September 2008, 100 copies had been produced—

“—I didn’t know that! It doesn’t surprise me, but that’s not a fact I had to hand.”

How did it feel reaching 100 copies in 2008, and did it feel like a success then?

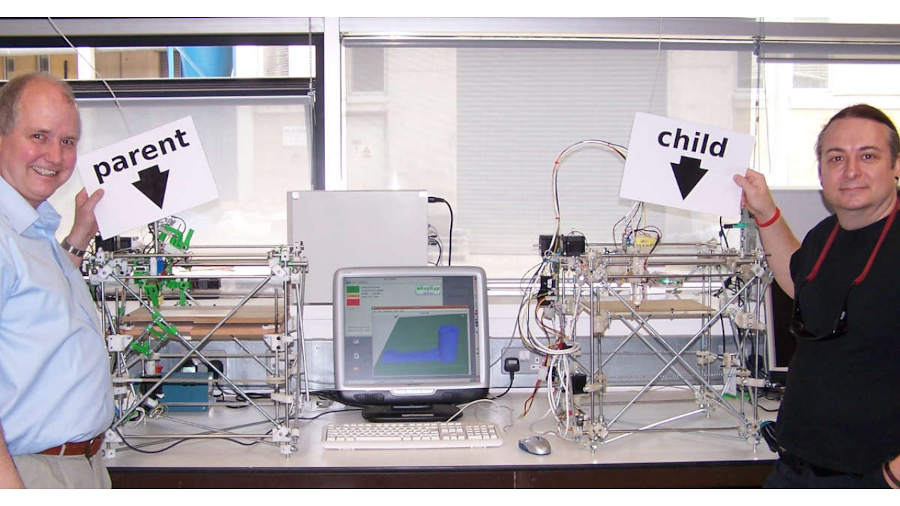

“It did feel like a success then because it worked technically, and the criteria was success was the criteria of a university engineering research project — proving the tech works. The success we felt occurred when we made a complete copy of the machine. That was the point we knew it was going to work: it’s physically here, it works — you can’t argue with that. So that was from my perspective the most significant milestone in the project.”

How did your machines end up differing from the existing Stratasys machines?

“The original Stratasys machines used a closed heated chamber, and we thought we would try and get away without having to have one. One of the first RepRap inventions was the heated bed, and in turned out that just by having the heated bed when printing, you could achieve results that were almost as good as the whole heated oven chamber that the Stratasys machines used.”

And how did you create the filaments?

“Stratasys filaments were made from commercial extrusion machines with dies; we didn’t have these. But what you could buy was plastic 3mm welding filament used for car body repairs, and use a hot air gun on these, like welding metal. That was our initial idea for source of filament. 3m

“That was where the 3mm came from, that was the standard diameter. Subsequently we decided to go down in diameter because the 3mm filaments were not try very flexible, and we also needed to pass the filament though a flexible tube for some of the designs of the machine we were coming up with.

“In particular, one of the [projects] we did which we think was a RepRap innovation — we don’t know if any of the Stratasys machines before used this — which was to have the drive for the extrusion physically separate from the head which actually deposits the material, and connect them with a PTFE tube.

“That has a great advantage in that you can keep the head very light, and keep the motor and drive very cool away from the heated head. The internal diameter of the tube we wanted to use was 2mm diameter, so we settled on 1.75mm diameter filament to fit through the tube.

“It was Vik Olliver who had the idea of using PLA in the machines. Until then, all the Stratasys machines had been using ABS. I mentioned [earlier in the interview] the foam bed that Stratasys used, the problem with ABS is it doesn’t adhere well the to bed and tends to curl upwards when printing. PLA doesn’t suffer nearly as much from that problem, and is also biologically sourced, so not using up oil resources as it’s plant-based.

“So pretty early on, as soon as we discovered PLA worked well, we switched over almost everything we did to using PLA. HDPE [milk bottle plastic] mainly interested us as we had the idea of a recycler that would generate filament to go inside the machine, and milk bottles were the obvious thing to recycle as they were so ubiquitous, but again it was overtaken by PLA because it was so successful.

“The Recyclebots are a brilliant idea, particularly if you can make one from parts made in a RepRap, it’s an obvious thing to do…the more versatile the machine is, in the types of plastic you can accept for re-extruding, the better. There are a number of filament extruders now being sold, and there are some open source designs out there.”

Do you find it interesting that something that ended up being very well known arose from people who started the project without ever talking or meeting?

“It depended on the technology of the time. We had enough, for example Vik Olliver could design something in New Zealand, attach it as an STL file in an email, send it to us, and we would print it and put it in a cardboard box and send back to him in New Zealand, and he would have it in 4 or 5 day’s time.

“That allowed us to do things fairly easily without any personal contact at all. And it was entirely electronic. We had the ability to store databases of designs online so anybody could download them, for the mechanical parts and the electronics, basically the whole thing is a bunch of computer files in the same way you and I are strands of DNA. The ease with which things can be transmitted made the project very easy.

In your 15 minutes of work talk, you offer a defence against RepRap printers only being able to print around 65% of their parts, saying humans only built 60% of themselves with amino acids, etc. Does that suggest a contentment with the current levels of progress, rather than pushing for a fully self replicating machine?

“I’ve never been all that interested in producing a fully self-replicating machine, because it’s an idea with two tiny exceptions that biology has completely abandoned. Any organism is entirely dependent on an ecosystem of other living organisms in order to reproduce, and I don’t think that RepRap should be any different.

“RepRap is a self-reproducing thing. It lives in a world with of biology, principally the world of human beings, who are biological machines, so I don’t have a problem with the fact that most RepRap designs are 70% self-producing and 30% from outside. When the number of materials the machine processes get larger, and once we start printing electrical conductors that really will conduct electricity as much as metals, with ease, then the proportion of bits it can produce itself will increase. It’s bound to happen.”

So your belief is based on that there are so few things that completely self replicate, informs your opinion that we don’t need to push for it wildly — AKA a 100% self-replicating RepRap machine?

“Yes, it’s something that will happen when it’s easy to do, but it’s not something where I think we need to devote an enormous amount of effort to get an extra 3% — it’s probably more interesting to solve other problems.”

For me, I’d want to just do it all. I find it interesting that you use biological principles to say when you think enough is enough. For me I’d always want to do something more — I don’t keep myself to for example that biological example, where I’d go oh that’s fine or fall back on biology, so it’s interesting, I guess as a selfish human where I want to see it all happen and I’m impatient for it all.

“It’s not just natural self-reproducing systems and coming to the conclusion that none of them work well in isolation, it’s a little bit stronger than that, in that when we look at natural selection systems, that may well not be optimal.

“If there was a Darwinian organism being able to live completely independently of all other organisms, we’d see more examples of it. I can see no reasons why the machine should try and struggle against the equilibrium which Darwinian selection seems to have settled upon.”w

And you don’t think the rules change when things cease to be made from cells and become made from electronics instead? You believe those rules still apply?

“It seems that that would be the null hypothesis. You’ve got to have some exceptionalism argument to say why that would not be the case and I don’t see that exceptionalism argument really.”

How did it feel to be awarded to be awarded an MBE by The Queen for your services to 3D printing?

“Oh, that was very gratifying — I got this envelope with all sorts of crests and things all over it. I originally thought it was some kind of tax demand and then I opened it and realised what it was. It was a New Year’s Honour [a recognition system in the United Kingdom for remarkable achievements in different sectors] and you get to hear about it around November time.

“It’s very nice to be recognised by one’s academic colleagues and students, and people such as yourselves [us, 3DSourced, in the 3D printing industry], to receive this recognition by the nation into which one happens to have been born in and lived by geographical accident, is actually a very gratifying thing indeed.”

What do you think will be the end archetype — the final form — that will be the end design of FDM 3D printers?

“They address different problems. The latest things are these Infinite Z printers that have been made by Naomi Wu’s Creality colleagues and so on, from the original idea of White Knight by NAK3D Designs. That seems to be a very clever geometry because it allows infinitely large parts in a single dimension.

“It might well be that the final form is some sort of combination of belt printer and delta printer. If you imagine a delta assembly suspended over a moving belt axis then you can see that this would perhaps [combine] the advantages of both of those two approaches: delta moves much faster than a cartesian [3D printer] because the bits and pieces are lighter and so the forces involved when they are accelerated are much lower, and of course speed is important because you can print more quickly, so that might be the next version to come along.

You discuss the term Darwinian Marxism—

“—Yes, but that was me trying to wind people up.”

But many companies have made millions from it. Is this a bastardization of the original concept: Darwinian Capitalism?

“Yes, probably. It doesn’t bother me though — the world does what it does. And because the design’s open source and even if people close it off, the open source is still there so other people can adopt it if they want, and even if people close it off, the closed source people can copy it and justify it by the original RepRap license, so that’s quite an amusing thing. No court cases yet, but that might be quite an interesting thing.

“The phrase you’ve just quoted [Darwinian Marxism] was a bit of tongue-in-cheek really from me trying to wind people up. And I don’t know if it succeeded or not. I don’t take these things too seriously I’m afraid.

You’ve been a proponent of UBI (universal basic income) in the past. Could a self-replicating machine encourage UBI?

“To an extent in that it separates you from the need to buy things. We’ve already talked about how a 3D printer saves you money because you can print things that would cost you more to buy, so imagine a more versatile machine being able to give you a wider range of goods, particularly if it copies itself, then you can let your neighbour have one for the cost for the raw materials.

“The amount of money you’d need to start distributing to people to allow them to live without the necessity of being fully employed would reduce the more material goods they could obtain by other means, so yes it would help in that regard.

“But we’re up against a problem: if you look at the way which productivity has increased since the introduction of the microprocessor in the middle of 1970s, the amount of wealth produced has increased enormously, but wages haven’t kept pace. They kept pace before because we were needed to make things, but now we can make wealth without people. We’ve separated out the necessity for people in the creation of wealth, and the inevitable capitalist consequence of that is that people become less valuable, and that’s why wages haven’t matched productivity. The only way to counteract that is to take the wealth that productivity represents and start redistributing that, and UBI is probably the fairest way of doing that.”