4 Ways Militaries Use 3D Printing To Modernize

At 3DSourced we’ve covered everything 3D printing and 3D since 2017. Our team has interviewed the most innovative 3D printing experts, tested and reviewed more than 20 of the most popular 3D printers and 3D scanners to give our honest recommendations, and written more than 500 3D printing guides over the last 5 years.

3D printed fighter jets, plastic assault rifles and combat drones all spring to mind when considering 3D printing in the military.

And not without cause. With the rapidly advancing and naturally competitive industry of military-technology, these innovations are already showing signs of being on the horizon.

However, we’re still a way off from anything out of science-fiction. Instead, and much like many large manufacturers, most international militaries are currently experimenting with 3D printing as a way to improve the cost and efficiency of manufacturing equipment and buildings.

But that doesn’t mean that the industry is lacking in exciting projects. Indeed, military operations naturally demand a high degree of reliability and effectiveness from their equipment.

This means that militaries are generally more willing to invest time and money into 3D printing research than civilian sectors.

So, with that in mind, here are four ways that the military is using 3D printing today.

3D Printing and Military Logistics – The British Army

A common issue for foreign military deployments is that of supply. Whenever a deployment is stationed abroad and cannot supply itself locally, then it must rely on logistics from home.

This is especially true for deployments in hostile environments, or combat operations, where sourcing supplies locally presents an additional risk.

This is hardly a new issue, with foreign invasions from antiquity facing the same problem. Today, most modern militaries possess large and effective combat logistics networks to solve this very issue.

But that is just half of the problem. The other issue with supplying an army from home, is that it has always been incredibly expensive.

Although it’s not promising to remove the issue, the British Army has been experimenting with 3D printing as a way to reduce this financial impact.

The British Army in South Sudan

The British army is currently deployed alongside a UN peacekeeping operation in South Sudan. Speaking about the situation in 2018, a spokesperson for the Royal Engineers explained that:

“engineering in South Sudan has faced many problems. A stretched and fragile logistical supply route has resulted in difficulties resourcing components. However, we have resolved some of these issues through the use of a 3D printer. This is the first time this technology has been used by UK land forces deployed on operations. With a production time of often less than 12 hours, resources which would normally take weeks to be shipped or flown into country can now be printed on demand with significantly reduced costs.”

During the deployment, a UN hospital was to be erected in the city of Bentiu:

“In order to complete construction we are using the 3D printer to manufacture essential small parts, the lack of which was previously hindering the progress of the build.”

Although perhaps not the most exciting use of 3D printing on this list, this example does demonstrate the growing use of the technology within the armed forces, as well as how it is tangibly benefitting operations today.

The 3D printed “Submarine” – US Navy

Moving onto what is perhaps a more visually striking project, let’s talk about the US Navy’s 3D printed submersible.

Navy SEALS (Sea, Air, and Land) are the world-renowned special operations soldiers of the US Navy. To achieve the “sea” component of their designation, they routinely utilize specialized submersible vehicles to deploy on operations.

Currently, this is done with the SDV (SEAL delivery vehicle) submersible. These submersibles can covertly deploy soldiers to both land and sea targets. The current model, the Mark 8 SDV, has been in operational use since 1983.

However, like a lot of specialized military hardware, production of these SDVs is often takes a lot of time and money. The US Department of Energy states that “the cost of a traditional hull ranges from $600,000 to $800,000, and typically takes 3-5 months to manufacture.”

This price tag skyrockets when considering additional costs; technical and logistical support, engineering, and training for example. Indeed, when the UK was approved to purchase three vehicles in 2018, the official estimated program cost came to $90 million!

So, what happens to that number when you 3D print the SDVs instead?

The 3D Printed Seal Delivery Vehicle

In 2017 the Oak Ridge National Laboratory partnered with the US Navy to 3D print an SDV hull. Using large-format 3D printers, they created a concept hull out of six carbon-fiber composite sections.

This concept became the first 3D printed submersible hull ever produced by a world military. But perhaps the most notable finding from this prototype was its efficiency. The hull took only weeks to print, rather than months, and was 90% cheaper to produce.

This efficiency also opens up more operational uses for the vehicles. Could 3D printed SDVs be tailor-made for each operation? Could they even be treated as disposable insertion vehicles?

These questions were tangible enough for the Navy to approve the project for further testing, with the initial aim being that fleet-capable prototypes could be introduced as early as 2019… This may have been optimistic however, as no significant updates on the project have been released since.

Instead, the US Navy have revealed that the Mark 8 SDV will be replaced by a newer non-3D printed model, the SWCS (Shallow Water Combat Submersible).

Read more: our feature story on 3D printed boats

So, It’s Not a Submarine?

Interestingly, and as an aside, despite being commonly referred to as submarines because of their appearance, this is not technically true. As the soldiers are exposed to the water whilst using their SDVs, they are technically only “swimmer delivery vehicles,” essentially beefed up and militarized underwater scooters.

The Future of the 3D Printed Submarine?

With the potential benefits it highlighted, it’s unlikely that the 3D printed submersible project has been entirely abandoned.

However, with the US committing $38.8 million to its SWCS contract, it’s also unlikely that they’ll be replaced any time soon.

So, although it’s unlikely we’ll see fully 3D printed military submarines in operation any time soon, it is now at least both a proven and desirable concept.

3D Printed Covid Swabs For The Swiss Army

Let’s look away from 3D printing’s combat potential for a moment and consider what the technology can bring to deployments on home soil. With a recent example of pushing boundaries coming from the Swiss Army’s use of 3D printing during the Covid-19 pandemic.

During the pandemic’s height in 2020, the world experienced an international shortage of Covid test kits, specifically, the swabs. With so many countries racing to test their populations, demand for the swabs quickly outpaced manufacture.

Switzerland, concerned by the shortage, and the prospect on being totally reliant on international supply lines, turned to its Army to develop an in-house solution.

Designing the Swabs

However, this wouldn’t be a simple case of 3D printing an existing design. Medical swabs of this type, (nasopharyngeal swabs) need to be long, strong, flexible, and feature a bristled section, with an intentionally weak section that allows the bristled end to break off.

Whilst converting all these attributes to a 3D printable medium was certainly possible, it would be quite the undertaking to create swabs that were also mass-producible, and able to stand up to the scrutiny of clinical testing.

To achieve this, the Surgeon General of the Swiss Armed forces partnered with medical technology company GobiX GmbH, creating a multi-disciplined team to develop a new swab design.

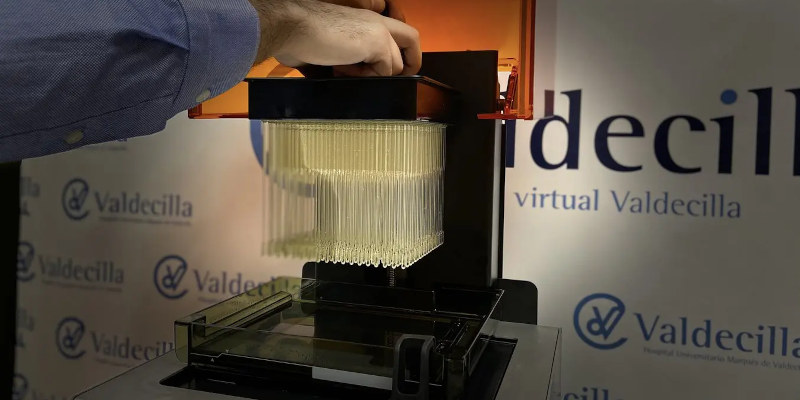

The team experimented with 3D printing the swabs. They used non-toxic resin and had to ensure that the swabs could survive an autoclave (a sterilization machine that subjects the swabs to lots of heat and pressure).

The team began testing with a selection of Formlabs resin 3D printers, specifically the Form 2 and 3. They quickly found success, with 3D printing allowing them to produce swabs quickly.

Indeed, similar testing in Spain using the same 3D printers were able to print 650 swabs every 24 hours.

Soon after Switzerland’s design was completed, the swabs also passed their clinical testing, becoming CE-Certified and fit for medical distribution.

Once distribution began nationwide, Switzerland became one of the first European countries able to fill their own demand for Covid swabs independently.

The Concrete Barracks Race – US Armed Forces

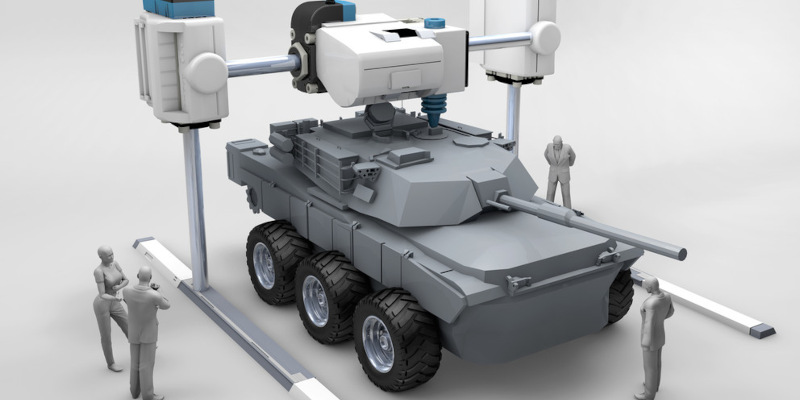

Over the past 5 years the US military has been experimenting with 3D printing concrete as a way to construct buildings rapidly and economically.

In 2017 the Army constructed a 3D printed B-Hut (type of barracks) in a Champaign Illinois research laboratory. The project demonstrated the potential efficiency of the technology, with each hut using half the shipped materials and 62% less manpower than the conventional plywood design.

In 2018, the Marine Corps printed another prototype barracks in the same Illinois facility. At the time it became the “largest continuous 3D concrete print of a building in the western hemisphere.”

Although the building never became operational, the Marine Corps still has faith in the merits of continued research.

Speaking about the project, Captain Matthew Friedell stated that:

“traditionally we build houses, schools, and homes where a natural disaster has happened… If we can just set up a machine, we can guarantee quality, consistency, and ideally we can just leave the machine there to start rebuilding those communities.”

Despite their strides however, neither force would be the first to complete and use a functional 3D printed barracks. Both would be beaten to the punch by the Texas Military Department.

Everything’s Bigger in Texas

Rather than being controlled by the national government, the Texas Military Department serves as an armed force of the Texas government itself. As such, its Adjutant General is even appointed by and reports to the Governor of Texas.

Their involvement with 3D printing came when they partnered with construction company ICON to build a new and innovative barracks for one of their military training centers.

Located in the Swift Training Centre in Bastrop Texas, the building became the largest 3D printed structure in North America.

With the completed project only being unveiled this month, this barracks is not only the newest project on this list, but it’s also currently the first and only 3D printed barracks currently in operation.

Evan Loomis, the CEO of ICON, explained how the structure was bult. “We have a foundation, the printer shows up, and it begins printing almost like a layer of cake… And so, you print up to the very top of the wall, and then you put on the roof in the traditional way. And you’re able to do it with just incredible speed.”

In this way, the Texas Military Department were able to take what had had up until now been prototypes and exciting concepts, and actually put them to use for the first time.

Being such a new development, it’s unclear how the soldiers using this facility feel it compares to a traditional barracks, but it still serves as an exciting prospect for the technology’s continued use.