6 Amazing 3D Printed Wind Turbines: Free Energy, Bubbles, and More!

At 3DSourced we’ve covered everything 3D printing and 3D since 2017. Our team has interviewed the most innovative 3D printing experts, tested and reviewed more than 20 of the most popular 3D printers and 3D scanners to give our honest recommendations, and written more than 500 3D printing guides over the last 5 years.

Did you know that it’s possible to 3D print your own wind turbine?

Now, people installing wind turbines on their property is nothing new, be that for free energy generation, aesthetics, or simple novelty.

Spending around $100 on a wind turbine, and mounting it high enough, can generate a continuous power output of 600watts. Practically speaking, this is enough to recharge a car’s battery, run a coffee machine, or keep a small fridge-freezer running indefinitely. Pretty good for a turbine not much bigger than a football.

But $100 is still $100, so it’s unsurprising that there are plenty of examples of people building their own. DIY turbines have been made from car alternators, ceiling fans, and there’s even a case from the UK involving kites attached to a bike!

You may not have a spare ceiling fan laying around, or the engineering know-how to turn it into a working wind turbine; but if you’ve got a 3D printer, then you’ve got more options than you think. Here are three ways to 3D print your own wind turbine!

1. Just for Show: 3D Printed Wind Turbines for the Aesthetic

While we will explore the ways that 3D printed wind turbines generate free power, it’s worth remembering that for many people, a wind turbine exists mainly for aesthetics.

And luckily for them, there exists a wealth of open-source files ready to be printed into your very own kinetic ornament. And these aren’t simple wind spinners either, with the following examples showing off how 3D printing can make potentially complex models accessible to even the least technically-minded individuals.

Here’s some cool 3D printed wind turbine projects that, while they don’t work and provide power, are just really cool and innovative designs.

Jacky Wan’s VAWT Wind Turbine.

Jacky Wan, also known as “Valcrow” online, designed this wind turbine model upon the request of Ultimaker in 2016.

At the time, Ultimaker were releasing their “Ultimaker 2+” 3D printers, and intended to use this model to show off their new line’s capabilities.

Jacky Wan came up with a desktop-sized Vertical Axis Wind Turbine (VAWT), so-called because they stand upright with their generators and gearboxes mounted on the ground, allowing them to work in any wind direction. His design, in particular, was notable because the model’s pieces could be easily snapped together without any adhesives or fasteners, allowing it to be easily reproduced by end-users.

Although the design was a promising demonstrational piece for Ultimaker, Valcrow’s model was just that, a model. A generator or gearbox was not incorporated into the design — so it’s just an ornament.

That being said, if you do want to make something more complex, then you do have options.

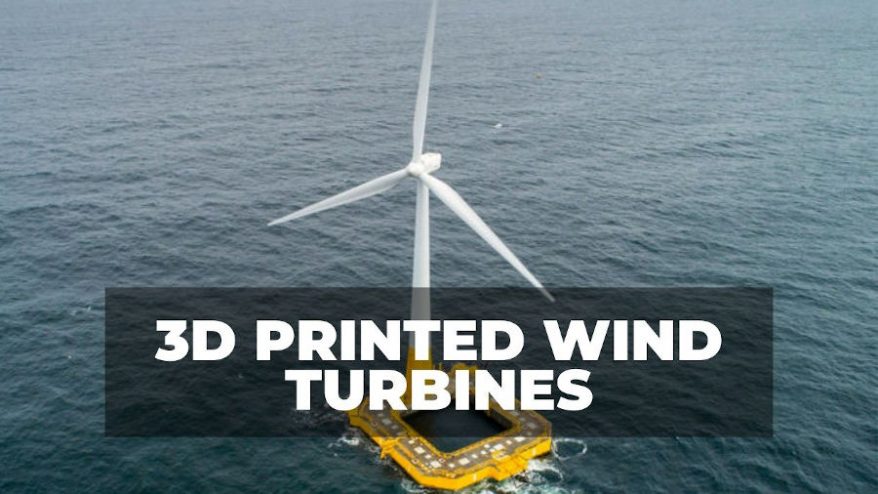

Nilheim Mechatronics’ 3D Printed wind turbine

Unlike Jacky Wan’s design, this model resembles a more conventional wind turbine, with an upright construction and propeller style blades. What perhaps separates this turbine from others though, is its use of functioning internal gears.

Will Cogley, the turbine’s designer, was sent a Makeblock 3D printer, and decided to design a wind turbine model to test his new printer’s capabilities. He explained that:

“It’s loosely based on what a real turbine looks like on the inside, and by pointing a fan at it you can make the turbine spin and you can see the gears moving… I was extremely pleased with the quality of the gears I managed to print. I even managed to produce some tiny little gears in areas using the same settings and they came out gorgeous.”

Will Cogley

Provided you already own a 3D printer, these two examples should come in at under $100, and demonstrate the flexibility that 3D printing allows for when choosing just how you want your wind turbine to look.

But what if you don’t want an ornament? What if you want it to generate power?

2. 3D Printed Power Generating Wind Turbines

Although far from impossible, building a homemade wind turbine capable of storing or generating power is harder than it may initially seem.

This would help to explain why the majority of open-source wind turbine 3D printing files don’t include power generation components, with the instructions tending to either leave the end-user to figure it out, or admitting that the turbine is essentially an ornament.

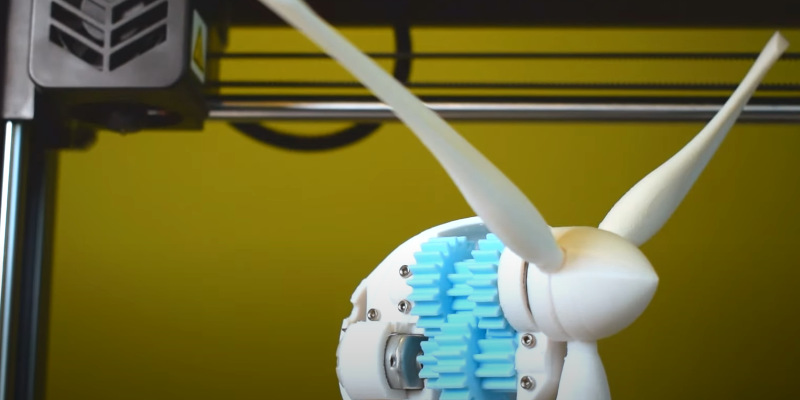

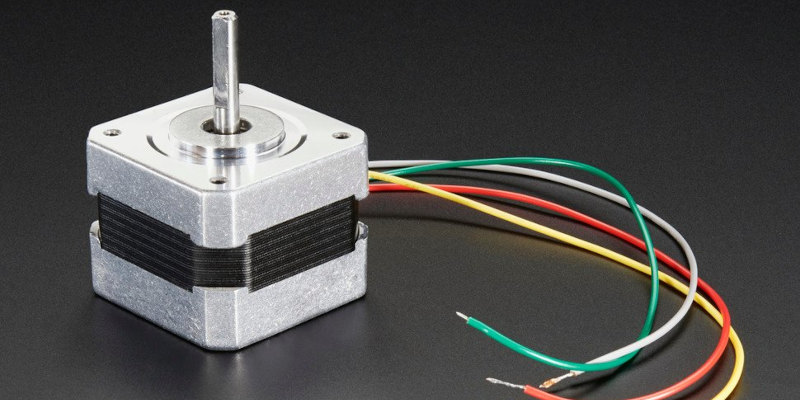

To sidestep the need to build your own generator, most 3D printed wind turbines capable of generating power use mechanical-style gears and pre-built stepper motors, which can then either be plugged into an appliance, or battery. Although this method allows the gears to be 3D printed, it also results in a less efficient system than a store-bought $100 wind turbine, with these DIY prints rarely generating more than 50 watts of power.

That being said, for something you put together on a desktop 3D printer, 50 watts of free energy isn’t anything to scoff at, and these two projects will show you exactly how it’s done.

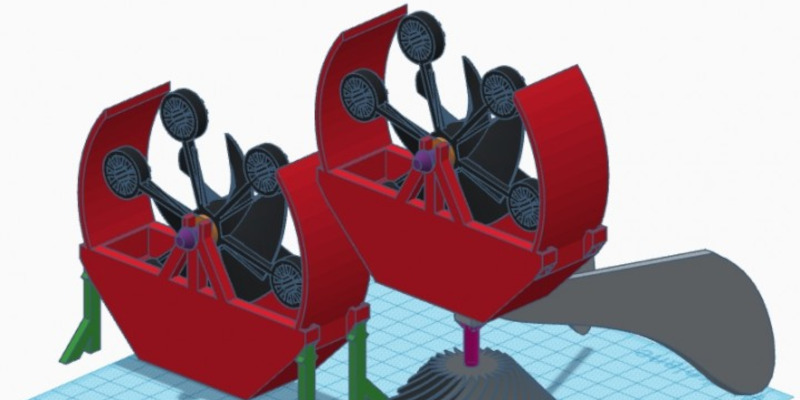

Daniel Davis’s “MKIII 50Watt 3D Power Turbine”

Published under his moniker, “3dprintable1”, Davis’ design strikes a balance between accessibility and function. According to Davis:

“This fully functional wind turbine has been specifically designed to be manufactured, assembled, and operated at home with its unique 3D printable design.” And his turbine’s many features seem to support this.

The “Power Turbine” features a passive variable pitch (PVP) design, which automatically controls the turbine’s blades to both optimize power generation, and to prevent dangerously fast spinning speeds in high-winds.

It’s modular, with end-users able to modify the size of the turbine’s blades and generator/stepper-motor without changing the base architecture or structural components.

The design is also efficient, with 95% of the turbine requiring no post-processing or print supports, further reducing the amount of plastic used and the cost of the final turbine.

All in all, the package here seems be just what most people are looking for, 50 watts (potentially) of ready-to-print power… Unless of course, you did want to have a go at building a generator yourself?

K&J Magnets

Similar to Davis’ design, K&J built a relatively simply upright wind turbine. However, they pushed the envelope by also building their own 3D printed generator.

The build was inspired by the inner workings of a sailboat’s windmill; they used magnetic wire to wind their own coils, then added stepped block magnets and a fidget spinner’s ball bearings to create a working rotor. The entire assembly was then housed in a 3D printed frame, creating their turbine’s generator.

Helpfully for us, K&J made the STL files used for their wind turbine available for free, as well as a video explaining their process. This allows you, should you feel so inclined, to build your very own wind turbine generator entirely from scratch.

However, this doesn’t mean that you should… when spinning their generator with a power drill, they only managed to generate 20Volts, and a single watt of power, barely enough to light up a LED.

K&J have quite transparently admitted that its practical value is limited:

“We’re not quite ready to disconnect from the grid using this device. It’s going to need some serious improvements to make more power. Still, it was a fun demonstration, illustrating the concepts behind larger wind turbines that do provide useful power!”

Bubble Power: Dylan Phillip’s mini turbine

Here’s a wind turbine you probably weren’t considering building until now. And yes, it may not net you any free electrical power, but it wouldn’t have been right to publish this listicle without mentioning bubble power!… Bear with me.

Dylan Phillips, also known as “Pikkle,” designed, printed, and released files for a wind turbine bubble blower.

For a device not much bigger than your fist, he managed to fit a lot of functionality into it too! Once the wind catches the turbine’s wands, they dip into the bubble solution, where the wind again blows the bubbles. If the wind changes direction, then the attached wind vane steers the whole turbine, allowing it to blow bubbles from any direction!

In addition to also making his files available for open-source download, Phillips also released two videos, one an animation detailing the turbine’s construction, and the other showing the device in action, with the 3D printed wands releasing a surprising amount of bubbles for their size.

Is bubble power too small for you? Let’s look at the scale’s other end then.

3. 3D Print Your Own Full-Scale Offshore Wind Turbine!

Okay, so this one may only really apply to millionaires, but… Did you know that full-scale offshore wind turbines are now beginning to be 3D printed?

In September 2021, a research partnership was announced between three companies: Energy provider GE Renewable energy, 3D printing company Voxeljet, and Fraunhofer IGCV (Institute for casting, composite, and processing technology).

Together, they set out to develop the world’s largest 3D printer ever built for offshore wind production, with the aim of 3D printing full-scale wind turbine blades.

Like many industries, the research was motivated by a desire to increase efficiency. 3D printing with sand molds is much cheaper than the composite and carbon-fiber materials used in conventional wind turbines. But most importantly, 3D printing could allow for these blades to be constructed on-site, rather than in a factory, and then transported in pieces to the often remote or offshore installation sites.

By reducing so much transportation, 3D printing offers massive environmental and bottom-line benefits.

Voxeljet announced on their website that “the partners expect to launch the project during the third quarter of 2021, with initial printer trials starting during the first quarter of 2022.”

So, who knows, maybe next year you will actually 3D print your own offshore wind turbine.

Other articles you may be interested in: