While excellent budget machines overall, the Ender 3 and its successor models (until the S1 and S1 Pro) still employ a Bowden extruder setup.

Stringing, inconsistent flexible material printing, and difficult retraction tuning, are just a few of the hiccups I’ve found with the Ender 3’s stock Bowden system.

That’s why I’ve decided to share the best Ender 3 Direct Drive upgrades I’ve found from my 2 – 3 years using this 3D printer.

Most users will find the E3D Hemera Direct Drive Kit, to be best for them.

It’s easy to install and produces great results without much tinkering – for a fraction of the cost of Creality’s own brand upgrade.

But if you have a bit of modding experience, you may prefer to print your own to save some cash. But beginners should definitely stick to a pre-built solution!

I’ll share the pros and cons of the most popular Ender 3 direct drives so you can upgrade with confidence.

|

|

|

|

|

$39.99

|

$152.77

|

$99.75

|

|

|

|

Let’s dive in.

Differences Between Direct Drive and Bowden Extruders

The main difference between direct drive and Bowden extruders comes down to the extruder’s position and configuration.

On a direct drive system, the extruder is mounted directly onto the print head for a much shorter path to the nozzle.

On a Bowden system, the extruder is generally mounted on the printer’s frame (or elsewhere, ‘away’ from the print head assembly) and connected to the hot end via a long PTFE ‘Bowden’ tube.

In practice, a direct drive system feeds filament almost directly from the extruder into the hot end. In contrast, on a Bowden system, the extruder feeds the filament first through the tubing, then into the hot end assembly.

Ender 3 Direct Drive Upgrade Options

Best Ender 3 Direct Drive Upgrades

- E3D Hemera Direct Drive Kit: Best Overall & Premium Pick

- Micro Swiss Direct Drive Kit: Great E3D Alternative Under $100

- Creality’s Direct Drive Upgrade: Best Budget Pick

- Triangle Lab Kit:

- Printermods MDD Kit

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Ender 3 Direct Drive Upgrade Kits

A quick search will reveal a host of kits for upgrading the Ender 3’s stock Bowden to a direct drive configuration. These kits provide all the necessary components and parts alongside in-depth guides.

They are widely considered the easiest way to upgrade the Ender 3 to direct drive. They are also guaranteed to work out of the box and provide a more stable, reliable printing experience.

However, as they are manufactured solutions, they tend to cost more than a DIY upgrade – expect to pay anywhere from $40 for budget options all the way to north of $100 for premium kits.

Note that not all kits are designed for all Ender 3 versions, so check compatibility and whether companies provide guides for the different printers and specific STL files for mounts and brackets.

DIY Ender Direct Drive Upgrade

A much lower-cost alternative to a kit is a DIY Ender 3 direct drive upgrade.

The main idea behind a DIY upgrade is to utilize as many factory Ender 3 parts as possible. Then, 3D print new parts to cut costs. There’s also an emphasis on further customization should you want to include new components such as an extruder or hot end.

The installation process takes longer and you’ll have to solve any potential problems yourself.

Stability can also be an issue as the brackets aren’t subject to tight manufacturing tolerances, but given their popularity, there’s no shortage of mods, guides, and videos to help you out should problems pop up.

Here’s a brief breakdown of the steps involved:

- 3D print a direct drive bracket mode of your choice.

- Dismount the extruder, stepper motor, Bowden tubing, hot end assembly, carriage and print head casing/shroud per instructions.

- Mount the 3D printed bracket onto the X-axis carriage.

- Mount the motor and extruder feeder system onto the 3D printed bracket.

- Wire as instructed.

- Insert a cut of PTFE tubing into the Hot End and re-attach.

- Assemble the print head cashing/shroud.

Buy an Ender 3 S1/S1 Pro

Lastly, if the upgrade route isn’t for you, you can also consider buying a new printer entirely – either an Ender 3 S1 or Ender S1 Pro, both of which come with a Sprite Direct Dual-Gear Extruder system as standard.

The lightweight Sprite system extends the Ender 3’s material compatibility to various flexible filaments thanks to dual chrome steel gears, a 1:3.5 gear ratio, and an 80N pushing force.

They are also the most sophisticated Ender 3 versions yet, ironing out many of the downsides of the original trio, with automatic bed leveling, PC spring steel magnetic build plate, and dual Z-axis thrown in for an overall better 3D printing experience.

Best Ender 3 Direct Drive Upgrade Kits

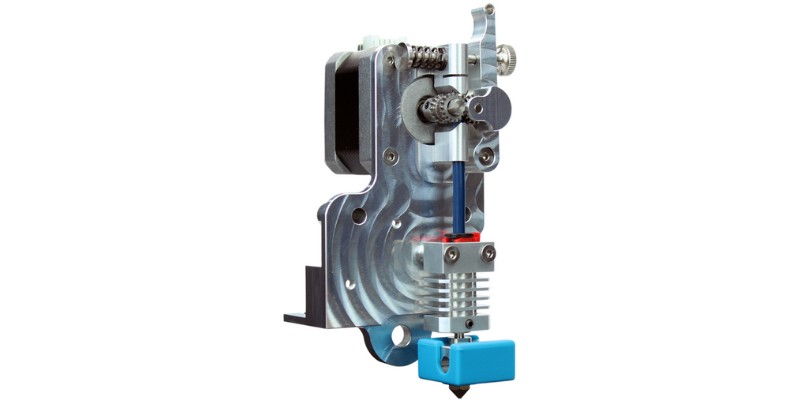

E3D Hemera Direct Drive Kit

- Price: Check on Amazon here

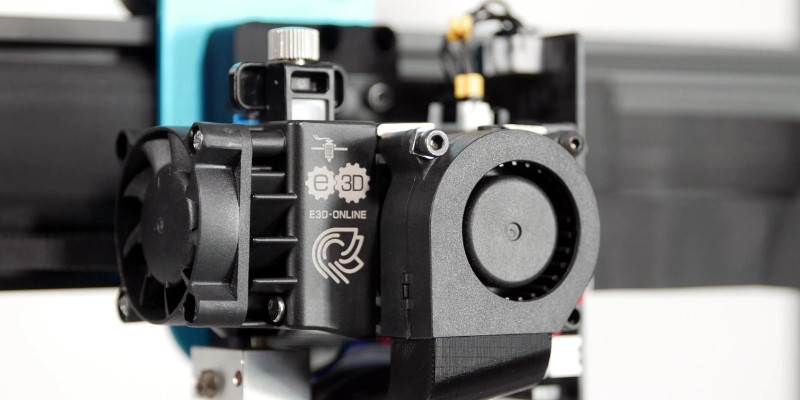

If you’re looking for a frictionless direct drive Ender 3 upgrade, few rival the mighty E3D Hemera for convenience.

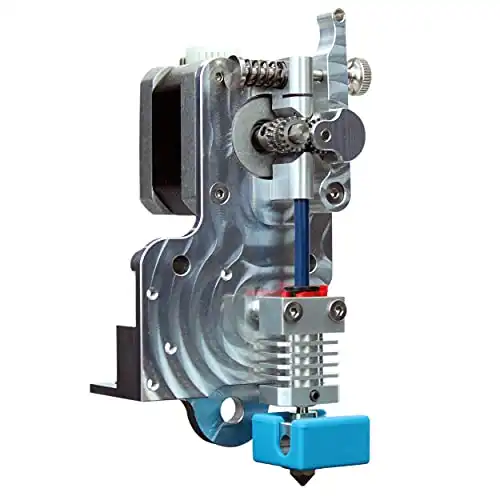

The kit combines all the parts needed for the upgrade, including a stepper motor, E3D V6 hot end, extruder, and all the hardware required. Compatibility is therefore guaranteed, and from the get-go, you know every part is designed to work with no issues.

E3D also provides an in-depth, step-by-step guide to upgrading the Ender 3 and Ender 3 V2, even providing STL files for the required adaptor mount and fan duct.

Once installed, the Hemera is nothing short of a premium, highly responsive direct drive extrusion solution, providing superb grip, fine control, responsiveness, and excellent performance with flexible filaments.

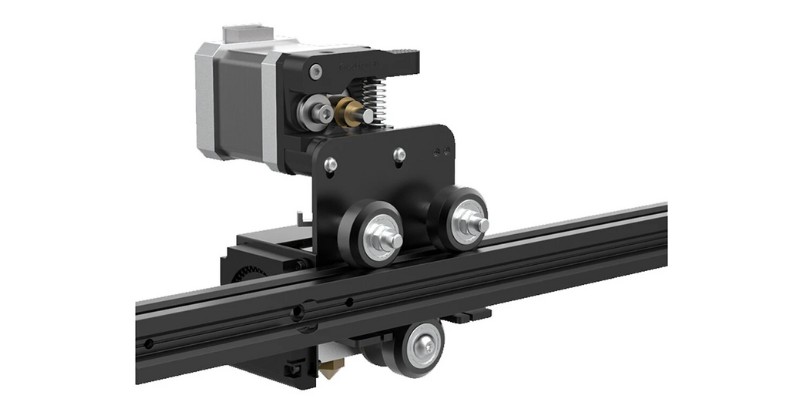

Micro Swiss Direct Drive Kit

- Price: Check on Amazon here

The Micro Swiss Direct Drive Kit is another highly recommended Ender 3 direct drive upgrade kit, which requires no modifications or additional brackets to install.

It recycles the existing extruder stepper motor on the Ender 3 and keeps all the parts tied to a sturdy central mount. Micro Swiss’ excellent upgrade guide greatly simplifies what is quite an involved installation.

The kit includes Micro Swiss’ world-renowned all-metal hot end, CNC precision cut gears, a dual-drive train, and an adjustable filament grip.

In practice, the Micro Swiss Direct Drive Kit transforms the Ender 3 into a far more precise printer, capable of delivering superb flexible filament prints.

Creality Ender 3 Direct Drive Upgrade Kit

- Price: $40.00 — Check on Amazon here / Creality store here

While kits generally cost more than a DIY upgrade, Creality’s Official Ender 3 Direct Drive kit bucks that trend, costing an affordable $40, a price which is hard to beat.

It arrives fully assembled and ready to mount, and as it’s designed specifically for the Ender 3, installation is as easy as it goes.

Simply remove the existing carriage, wire the new motor and hot end, then mount the new assembly by simply sliding it onto the V-slot X-axis carriage.

As a complete assembly, it features an extruder, stepper motor, complete nozzle kit, casing, and fan – all direct from Creality.

If you’re looking for value and don’t mind sacrificing some of the niceties (pre-made parts and guaranteed stability to name a few), and overall build quality provided by kits more than twice the price, the Creality Ender 3 Direct Drive Upgrade Kit is a solid option.

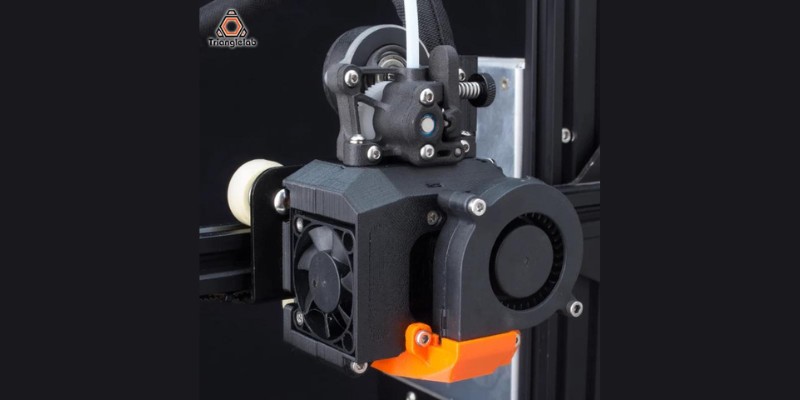

Triangle-Lab Direct Drive Kit

- Price: $80.00

The Triangle-Lab Direct Drive Kit marries quality components with easy installation while costing less than the big-name options.

It includes everything you’ll need for an Ender 3 direct drive upgrade, even throwing in parts other manufacturers generally expect you to print yourself.

As such, it’s very much a complete package:

- NEMA 17 stepper motor

- Low noise fan

- V6 Hot End

- Dual drive nickel-plated extruder

- All-metal heat break

- Aluminum alloy heat block

- PETG duct, support, bracket, and print head casing

Adaptability is also a core feature of the Triangle-Lab Direct Drive Kit: it works with all manner of configurations, including different hot ends and auto-level probes to suit a wide range of needs and requirements.

Printermods MDD Direct Drive Ender 3 Upgrade

- Price: $35.00

Bridging the gap between a kit and a DIY upgrade, we have Printermods MDD Direct Drive Ender 3 Upgrade.

It costs far less than most premium kits but features a premium CNC cut bracket that’s far sturdier and more reliable than a 3D printed alternative.

The kit includes a bracket, hardware, wiring, and fittings to repurpose the Ender 3 stock extruder, hot end, and print head assembly.

Installation should take no longer than 30 minutes.

The design guarantees compatibility with virtually all hot end and extruder combinations thanks to a host of mounts and holes on the bracket itself, ideal if you’re running something a little more exotic than the stock Ender 3 parts such as a Bondtech BMG, E3D Titan, or Micro Swiss All-Metal Hot End.

DIY Direct Drive Ender 3 Upgrades

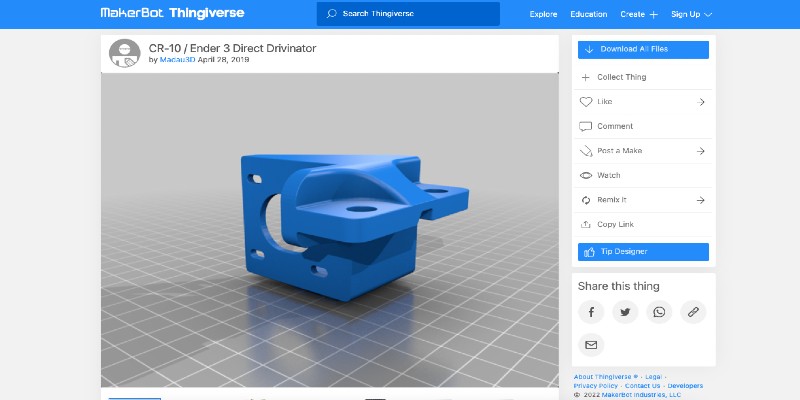

Ender 3 Direct Drivinator

The Ender 3 Direct Drivinator is an extremely popular DIY upgrade bracket designed to sit on the existing X-axis carriage with space for the stepper motor and extruder.

The Ender 3 Direct Drivinator stands out for offering easy installation sided by a sturdy bracket design.

Aside from the printed bracket, all you’ll need is a stepper motor extension cable (around $5) routed to the Ender 3’s mainboard.

Otherwise, it utilizes all the Ender 3’s existing parts, stepper motor, and extruder included, but is designed to play well with different hot ends and extruders if you choose to upgrade those too.

Petsfang

Petsfang has fostered an excellent reputation among DIY 3D printer enthusiasts for offering novel, low-cost, but professionally engineered solutions to patch up the Ender 3’s more pressing downsides.

The direct drive design involves buying a Bondtech BMG extruder ($80), but this is the only expense other than the cost of filament and screws and is a major improvement over the Ender 3’s stock extruder.

From there, the Petsfang offers a complete two-part 3D printed bracket with mounts for the Ender 3’s existing extruder stepper motor, BMG extruder, and fan.

We also like the Petsfang design because it can not only work with the stock Ender 3 hot end but also with popular upgrades such as the E3D V6 hot end.

It’s also compatible with a NEMA 17 pancake stepper motor if you want a lighter alternative to the stock Ender 3 motor.

Direct Drive Extruder Mount

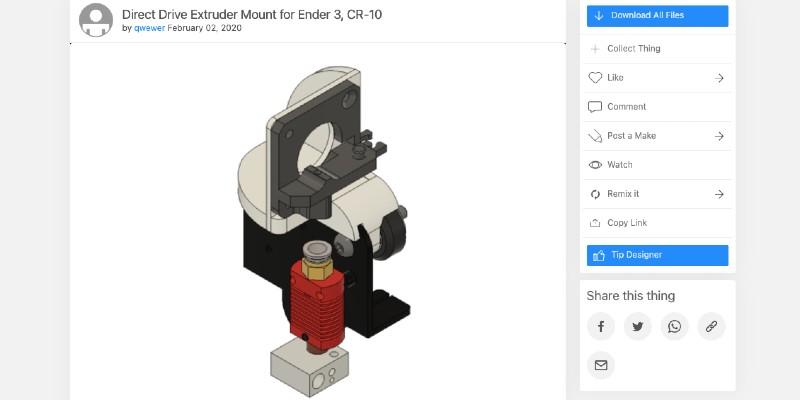

Though not radically different from the options above, this Direct Drive Extruder Mount from Thingiverse contributor qwewer is another solid DIY Ender 3 direct drive upgrade option.

It doesn’t require any major modifications to the printer, messy firmware tweaks, or any additional bought parts other than an extension cable for the stepper motor.

The 3D printed bracket press fits onto the V-slot pulley wheels, sitting on the X-axis carriage plate with an extra groove, adding additional stability.

It’s also compatible with fan duct upgrades such as the popular Hero Me Gen 4 and 5, and with minor tweaks, it can accommodate an automatic bed leveling probe such as the BL Touch or Creality’s CR Touch.

Advantages of Ender 3 Direct Drive Upgrades

Improved Filament Control

A direct drive system offers improved filament control and responsiveness, generating more precise prints.

Because the extruder is attached directly to the print head, the distance between the two is shorter, meaning a tighter, more constrained path. The stepper motor doesn’t work as hard for the same amount of extrusion, meaning improved fine control and higher printing resolution.

You can learn about the best filaments for Ender 3 in our full guide.

Better Retraction Control

Similar to better control of filament extrusion, an Ender 3 direct drive upgrade allows for more accurate and faster retraction because the filament path isn’t as long, unlike a Bowden system, where the extruder has to work the filament through a lengthy PTFE tube linking it to the hot end.

Better Flexible Printing

A direct drive system allows the Ender 3 to deliver consistent and reliable flexible prints because the shorter filament path reduces the potential for clogging, jamming, slipping, and snapping.

Reduces Stringing

The better retraction control afforded by an Ender 3 direct drive upgrade leads to less stringing, one of the major downsides of a Bowden system.

You’ll spend less time post-processing your prints.

FAQs

Is Ender 3 direct drive better?

This question is the source of much debate, and the answer ultimately comes down to your printing ambitions.

For flexible materials, a direct drive is a far better option than a Bowden system due to the shorter filament path, better Ender 3 direct drive retraction settings and performance, and finer extrusion control, but for standard filaments like PLA and ABS, the Ender 3’s stock Bowden setup is more than up to the task.

Is Creality Ender 3 direct drive?

No, the Creality Ender 3 3D printer uses a Bowden rather than a direct drive extruder configuration.

What is the best direct drive for Ender 3?

We recommend kits such as the E3D Hemera, the Micro Swiss Direct Drive Kit, the Triangle-Lab Direct Drive Kit, and the Creality Ender 3 Direct Drive Upgrade Kit for those on a tight budget.

How do you make an Ender 3 direct drive?

There are two main options to upgrade the Ender 3 to a direct drive extruder configuration.

First, buy a direct drive upgrade kit. Second, install your own DIY solution using the Ender 3’s existing components and 3D printed parts

Does Ender 3 Have a Direct Drive?

The Ender 3 range does not come with a direct drive as standard, with one exception – the Ender 3 S1.

If you enjoyed this article, check our other Ender 3 upgrade guides to learn more:

- Upgrade your Ender 3 with a Laser Cutter / Engraver

- Creality Ender 3 Dual Extruder Upgrades

- The Best Ender 3 Extension Kit Add-ons

- My Top Auto Bed Leveling Upgrades for Ender 3

- Learn About All Types of Ender 3 Fan Upgrades in this Comprehensive Guide

- The Best Hot-end Upgrades for Ender 3 Pro/V2.