3D printing jewelry rarely means 3D printing actual wearable pieces made from filament or resin, but instead using a jewelry 3D printer to create high-resolution wax models of the eventual gold or platinum design, used to create a mold that is burned out and cast via investment casting or lost wax casting.

And, rather than having to pay $25+ for someone to 3D print it for you, buying your own wax 3D printer for jewelry saves you serious money (can cost $1-2 to print your own) — and gives you more control over your production.

So, we put together our list of the best wax 3D printers for jewelry, including resin and wax printers, and in every price range, to help you pick the best jewelry printer for you.

|

|

|

|

|

$699.99

|

$959.99

|

$3750

|

|

|

|

| Name | Build volume (mm) | Price | Where to buy |

|---|---|---|---|

| Elegoo Mars 2 Pro | 129 x 80 x 160 | $250 | Elegoo here |

| Phrozen Sonic Mini 8K | 165 x 72 x 180 | $699 | Phrozen here |

| Anycubic Photon M3 Plus | 245 x 197 x 122 | $699 | Anycubic here |

| Anycubic Photon M3 Max | 300 x 298 x 164 | $1,049 | Anycubic here |

| Peopoly Phenom | 276 x 155 x 400 | $1,999 | Matterhackers here |

| Formlabs Form 3 | 145 x 145 x 185 | $3,499 | Dynamism Store here |

| Solidscape S325 | 6″ x 6″ x 4″ | Quote | Get a quote |

| Flashforge WaxJet 300 | 289 x 218 x 150 | ~$50,000 | Get a quote |

| EnvisionTEC D4K Jewelry | 148 x 83 x 110 | Quote | Get a quote |

What are 3D printers for jewelry?

Resin 3D printers are considered the best 3D printers for jewelry. They use specialized castable wax resins, which rather than going from solid to liquid when heated, transition directly into a gas from their solid state.

FDM 3D printers are very rarely used as 3D printers for jewelry. They are not capable of the same resolutions, crisp surface finishes or accuracies required for intricate and delicate jewelry pieces. Jewelry is incredibly highly detailed — an inaccurate mold will create inaccurate and unimpressive jewelry.

Additionally, the better the jewelry 3D printer quality, the less finishing the resulting jewelry piece will need to perfect it.

What do jewelry 3D printers make?

Usually they 3D print wax jewelry molds, for example ring designs before any stones are set, or individual chain links.

However, they can also be used to create like-for-like “fitting pieces” for testing the fit of an as-yet unmade ring for a client’s finger. Though making the final ring would be expensive and take time, an exact replica can be made on a jewelry 3D printer in just minutes to test the sizing.

This saves the trouble of creating a piece just to find it doesn’t fit properly. Whereas for jewelry molds specialized castable resins are required, for these fitting pieces standard resins can be used.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

The Best 3D Printers for Jewelry

Elegoo Mars 2 Pro: Cheapest jewelry 3D printer

- Jewelry 3D printer price: $250 — Available at Elegoo store here / Available on Amazon here

- Build volume: 129 x 80 x 160 mm

Pros

Great value for great resolution.

Works at quick speeds.

Cons

Newer and high-spec models are available.

Featuring a 6-inch monochrome LCD screen offering HD 2K resolution, the Elegoo Mars 2 Pro offers precise jewelry printing for the price. Rather than DLP or SLA, the Mars 2 Pro uses LCD printing to cure entire resin layers at once, quickening print speeds and able to print at 30-50mm/h.

Other 3D printers for jewelry on this list offer better quality, but for the price the Mars 2 Pro is a great option. It is sturdily built with its CNC-machined aluminum structure for better stability, and the mono LCD is upgraded for improved lifespan to save you money over the long term. It’s one of the best 3D printers for jewelry under $500.

The Elegoo Mars has Z-axis resolutions of up to 0.00125mm, XY-resolutions of 0.05mm, and weighs 6.2kg. It also supports 12 different languages, so if you’re not a native English speaker you can choose your own language.

The video below even shows, from start to finish, how accurately you can make wax models for gold jewelry using a standard Elegoo Mars. Even this standard version produces good quality wax models, and the Elegoo Mars 2 Pro comes with several upgrades on the original.

However, new and better Elegoo printers have since come out, which can create even more precise and intricate jewelry features. If you have the budget, consider upgrading to the Elegoo Mars 3 or Mars 3 Pro for the best resolutions.

Phrozen Sonic Mini 8K: Extremely high-quality 3D printer for casting

- Price: Check latest price at Phrozen here

- Build Volume: 165 x 72 x 180 mm

- XY Resolution: 22 Microns

- LCD Size: 7.1”

- LCD Resolution: 8K

- Material Compatibility: Resin

Pros

Unmatched resolution.

Ultra-stable dual linear rails ensure great stability.

User-friendly operation.

Cons

Small build volume for the price.

The Phrozen Sonic Mini 8K is the latest entry to Phrozen’s well-respected line-up of resin 3D printers. Setting it apart from the rest of the Phrozen stable and many other manufacturers is an 8K LCD (7500 x 3240 px) combined with an XY resolution of 22 microns, positioning it as one of the most detailed consumer-grade printers around.

The machine effectively doubles the 4K resolution found on most printers released in the last year or two, offering unparalleled results to satisfy even the most demanding jewelry makers and designers.

This allows you to create feature-rich, highly detailed, intricate parts and models with superb surface finish. For jewelry making, the Sonic Mini 8K can print extremely intricate resin molds for rings, broaches, bracelets, earrings, and much more.

The quality is largely unsurpassed in this price range, and the Phrozen Sonic Mini 8K should be at the top of the list of anyone serious about using 3D printing to create market-ready, production-grade jewelry casts from the first print onwards.

Further enhancing the Phrozen Sonic Mini 8K’s printing abilities is an ultra-stable dual linear rails setup, which ensures superb stability, mitigating print errors, alongside a frosted, laser-cut build plate that promotes fantastic adhesion, even on small parts and models like jewelry.

Finally, the light array is what Phrozen calls a linear projection LED module. Cutting through the jargon, this simply means excellent light uniformity for sharper, more consistent results.

The 165 x 72 x 180 mm build volume is large enough to batch print several casts at once, though it may be a little small for larger businesses. However, it makes up for this with user-friendly operation, and, again, a level of quality unheard of even a few years ago.

We recommend pairing the Phrozen Sonic Mini 8K with Phrozen’s own castable resin, notably the Phrozen Castable Resin W40, Phrozen Castable Resin W20, Phrozen Castable Dental & Jewelry Resin. The printer is compatible with third-party castable resins, but the quality does take a small hit, so it’s best to stick with Phrozen’s optimized resins for the best results.

Anycubic Photon M3 Plus/Max

- Price: $700-$1,000 — Check latest price at Anycubic here / Amazon here

- Build Volume: 245 x 197 x 122 mm / 300 x 298 x 164 mm

- XY Resolution: 34 Microns / 46 Microns

- LCD Size: 9.25″ / 13.6″

- LCD Resolution: 6K / 7K

- Material Compatibility: Resin

Pros

Large build volume.

Textured build plate offering superb print adhesion.

Fine details and features suitable for jewelry making.

Cons

The fans are very noisy.

With a 6K and 7K LCD resolution and 34 and 46 micron XY resolution respectively, the Anycubic Photon M3 Plus and Max produce high-quality prints stacked with fine details and features suitable for jewelry making.

However, the real benefit here is the large resin build volume compared to many similarly specced and priced 3D resin printers.

The Anycubic Photon M3 Plus boasts a 245 x 197 x 122 mm, while the Anycubic Photon M3 Max expands this to 300 x 298 x 164 mm – some of the largest in the budget resin market.

What this means for jewelry making, given that resin printers cure entire layers at once, is higher productivity: you can produce more jewelry at once, which is ideal for budding businesses looking for a cost-effective printer to kickstart a jewelry-making venture.

Both printers also come with several quality-of-life features that make these very easy to use and master. These include smart resin filing, a laser engraved build platform for superb adhesion, high-precision ball screw z-axis rails, and up to 60-100 mm/h print speeds, so you can prototype quickly and efficiently before committing to a production run.

Though the Anycubic M3 Plus and Max pair well with third-party filament, they work best with Anycubic DLP Craftsman Resin. It’s optimized for precise prints with intricate features, and a perfect resin for jewelry prototyping. It has the added benefit of reducing shrinkage, and has a shorter exposure time to cure than most other resins.

Peopoly Phenom: large-scale resin printer for batch printing jewelry molds

- Jewelry 3D printer price: $1,999 — Available on Matterhackers here

- Build volume: 276 x 155 x 400 mm

Pros

Large work area for the price.

Super fast bulk printing.

Cons

Loud fans.

The Peopoly Phenom offers truly enormous printing volumes, almost unheard of for a jewelry 3D printer. For jewelers looking to produce many rings or other pieces simultaneously, this larger volume provides space for dozens of wax jewelry models. If you’re in demand for jewelry and want to make as many as possible then this larger build volume is crucial.

With its 4K high resolution projection quality using MSLA technologies, the Phenom produces crisp, accurate and consistent jewelry molds. MSLA takes elements from both LED and LCD technologies, the result being fast, accurate and repeatable jewelry 3D printing.

- The even larger version, the Peopoly Phenom L, is available here.

- For faster print speeds, the premium Peopoly Noir is available here.

The Phenom uses Chitubox resin 3D slicer, useful if you’ve previously used it previously on another printer. Overall, it’s one of the best 3D printers for jewelry, and a great choice for people looking to make large numbers of castable wax jewelry models.

Formlabs Form 3

- 3D for jewelry price: $3,499 — Available on Dynamism here

- Build volume: 145 x 145 x 185 mm

Pros

Extremely fine details and precision, ideal for jewelry.

The gold standard for professional resin printing.

Cons

Small build area.

Seen as the gold-standard in professional resin printing, the Form 3 is capable of fantastic precision, with its new custom Light Processing Unit (LPU) using lenses and mirrors to accurately print jewelry models.

For the price, the Form 3 offers 25-micron resolutions and very consistent and repeatable printing. For those looking for a 3D printer for jewelry able to produce the same design flawlessly again and again, or for producing custom intricate designs, the Form 3 can handle both without issue.

Formlabs make their own castable wax resins designed for jewelry with “crisp settings, sharp prongs and smooth shanks.” Within the Formlabs workflow therefore is a complete jewelry production process for wax models, though the Form 3 also excels as a dental 3D printer and in other industries, too.

Solidscape S325: best 3D wax printer for jewelry

- Price: Requires a quote

- Build volume: 6” x 6” x 4”

Pros

Designed especially for jewelry making.

Accurate and precise.

Cons

No support for Mac users.

Soliscape make specially designed jewelry 3D printers, so any Solidscape printer you buy is optimized for jewelry printing. Whereas other printers like the Form 3 are designed to excel in a number of industries, the Solidscape S325 is designed with jewelry wholly in mind.

The S325 is the cheapest of Solidscape’s jewelry 3D printer range. It offers great accuracy, material jetting wax models for the precise and effective investment casting of precious metals. Solidscape stress that all their models are castable in gold and platinum, and do not expand or shrink during the investment casting process.

The S325 is capable of 0.001-inch layer thicknesses, with accuracies of 0.005 inches. Overall, as a specialized 3D printer for jewelry, Solidscape have a rich history in jewelry 3D printing and can be trusted to deliver high-quality and precise ring wax models, time and time again.

Flashforge WaxJet 400

- Price: ~$50,000

- Build Volume: 289 x 218 x 150 mm

- Layer Thickness: 16 Microns

- Resolution: 1200 x 1200 x 1600 dpi

- Material Compatibility: Flashforge casting wax and dissolvable wax support material

Pros

Great for mass production with great quality.

Fast print speeds.

Cons

Not particularly large.

Unlike most of the other printers on our list, the Flashforge WaxJet 400 is aimed at established businesses for mass production with flawless quality. It employs multi-jet 3D printing technology instead of SLA, vastly improving production speeds, saving time and money, and shortening the time to market.

The machine produces casting wax patterns, not the final end-product jewelry. These casts are used for the final casting process, usually in metals, followed by polishing, stone setting, and sandblasting.

Though the 289 x 218 x 150 mm build volume isn’t particularly large, the printer is designed to work tirelessly at faster print speeds, improving productivity, with the printer able to churn out hundreds of models per day.

As Flashforge notes, the printer can produce up to 10kg of wax patterns in a single month. This is all done at an astounding 16-micron minimum layer height, beating the quality found on SLA resin printers, with high precision, high accuracy, and high detail results.

Due to the use of multi-jet technology, the Flashforge WaxJet 400 is limited to Flashforge materials. But rather than a constraint, these are optimized to make the most of the device’s capabilities.

These include FFWJ1100 and FFWJ1200, both wax-based casting materials, and FFMS3100, a wax-based support material that dissolves easily after the printing process to simplify post-processing, allowing for steep overhangs and clean bridges, even on the smallest rings.

EnvisionTEC D4K Pro Jewelry 3D printer

- Jewelry 3D printer price: Requires a quote

- Build volume: 148 x 83 x 110 mm

Pros

High-resolution professional-grade desktop 3D printer.

User friendly.

Produces very detailed parts.

Cons

Small build volume.

Described by EnvisionTEC are the highest resolution professional-grade desktop 3D printer, as well as claiming to have the fastest speed, the D4K is well suited to jewelry 3D printing. Speed and accuracy are key to jewelry production, with the printer’s 4K UV DLP projector able to create crisp wax models at speed to be cast into stunning jewelry pieces.

EnvisionTEC are the originators of DLP 3D printing, having pioneered the process more than a decade ago. Now, their advanced D4K Pro can produce accuracies of up to 25 microns in the XY resolution, and 1 micron on the Z axis.

The jewelry 3D printer works well with EnvisionTEC’s WIC100 Series wax material, used to then burn out and investment cast precious jewelry. Though it’s an industrial 3D printer costing over $10,000, larger jewelers will find the D4K one of the best 3D jewelry mold printers.

Buying Guide – Things to Consider When Buying a 3D Printer for Making Jewelry

Resolution

Resolution measures the level of detail a 3D printer can produce, hugely important for jewelry production. A higher resolution 3D printer can produce more accurate models, finer details, better surface quality, and more intricate details – all essential where the final aesthetic quality is so important.

In terms of the casting process, higher accuracy models ensure few issues and errors during the casting process, saving costs on instanced prototyping and batch production for the market.

On an SLA resin printer, we would recommend at least a 6K resolution LCD, ideally 8K, while on a multi-jet printer, anything below 20 microns provides sufficient detail for high-quality casts.

Build Volume and Print Speed

A larger build volume allows for larger individual parts, though this particular usecase doesn’t matter in jewelry making, where parts are small.

However, for batch printing jewelry casts, it’s absolutely key. Larger build areas let jewelry businesses print multiple models at once, an important consideration if your plans include large and frequent production runs.

Resin printers cure entire layers at once, so whether you are printing one model or a dozen, the print times are the same. So, you can print faster because you can squeeze more models into a larger build surface without upping the production time.

Cost

For a decent 3D printer for jewelry making, you can expect to pay upwards of $700, with prices surging to well over $50,000 for professional-grade machines.

As the saying goes, you get what you pay for, so if you are comfortable with a smaller-scale operation (and slightly less precise models), a more affordable printer is a viable choice.

Otherwise, we strongly recommend considering a more professional 3D printer, because more expensive machines offer better overall print speeds, build volumes, workflows, and, therefore, better productivity.

Resin Compatibility

Always check whether a 3D printer is compatible with third-party materials, or tied to the manufacturer’s materials, before locking in your choice.

Most importantly, check it’s compatible with castable resins or wax suitable for jewelry. Not all are (especially cheaper resin printers), which could result in an expensive mistake.

Note that castable resin tends to be more expensive than typical 3D printing resin. But due to the size of the models produced in jewelry making, models are fairly cheap to print.

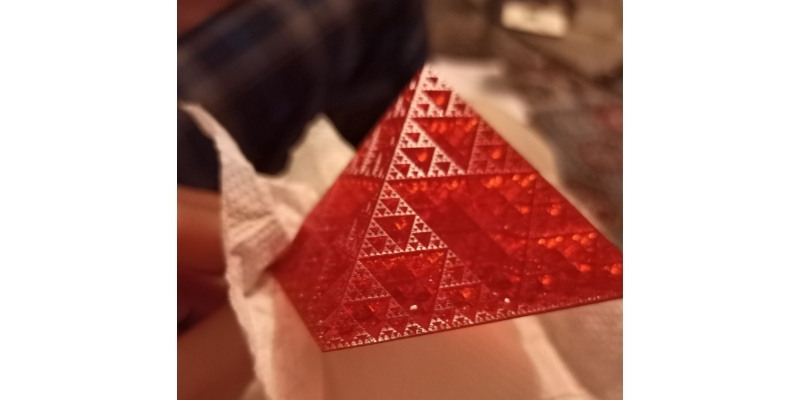

The Jewelry 3D Printing Process

- CAD File: Either design your own jewelry piece on CAD software, pay someone to design your desired piece, or pay for an existing jewelry STL file online and download it.

- Slice & Prepare: If not already an STL or other compatible file, export it as one. Then import it into your 3D slicer and slice it for printing.

- Print the model: Use a castable wax resin designed for jewelry model 3D printing.

- Molding: Pour your molding material over your wax jewelry model, and leave it to harden.

- Melt the wax: Heat your new mold so that the original wax model melts and evaporates, leaving a hollow empty space inside with the exact dimensions of your planned jewelry piece.

- Casting: Pour melted liquid metal e.g. gold, silver or platinum into the mold to cast it.

Can a 3D Printer Print Jewelry?

Yes, you can 3D print jewelry with a 3D printer using lost wax casting. The printer produced what is called a wax or castable resin pattern – a 3D model of the desired jewelry produced using a material that can melt away easily.

The pattern is then covered and surrounded in plaster. The block of plaster is then gently warmed to melt the wax/resin inside, creating a gap that matches the shape, size, and details of the jewelry.

The space is filled with melted metal like silver or gold. As the metal cools, it takes on the shape of the pattern, resulting in a finished piece of jewelry.

Can You Use 3D Printer Resin for Jewelry?

Yes, you can use 3D printer resin to produce jewelry, but only with more expensive castable resins, which are designed specifically for lost wax casting.

These differ from standard resin in that they are designed to melt away when heated up, much like wax, the material of choice for traditional jewelry casting. The idea here is that they are used to create plaster molds, melted, then replaced by molten metals to create jewelry.

What 3D Printers Do Jewelers Use?

Jewelers use 3D printers designed to print with castable resin, wax, or castable wax because these machines can print “patterns” – casts that are used in the lost wax casting process to create burnable molds.

When these molds are encased in plaster and then burnt away, liquid molten metal is poured in to create the final jewelry pieces.

How Much Is a Jewelry 3D Printer?

Jewelry 3D printers range from entry-level, consumer-grade machines from $700 to $1000, such as the Phrozen Sonic Mini 8K and Anycubic Photon M3, all the way to industrial, professional-grade 3D printers costing tens of thousands of dollars, such as the Flashforge WaxJet 400.

How Much Does It Cost to 3D Print Jewelry

Assuming 1kg of castable resin costs $100, and a 2g average weight of a castable ring, you can print 500 of these rings with 1kg of resin. This calculates the average cost at $0.20 per jewelry print. However, this doesn’t factor in unused resin, failed prints, post-processing, etc.

Advantages of owning a jewelry 3D printer

- Saves money long term: rather than paying a 3D printing service $20+ to print your mold for you, you can print your own wax jewelry molds for just a dollar each for lost wax casting.

- Control your own jewelry production: with the ability to print jewelry in-house, you control your own workflow and apart from resin shortages, cannot be slowed down by supplier failures. Your order will always be top priority.

- Fast: going from CAD model to a piece ready to be investment cast is quick, especially when you can print and cast everything in one place.

- Very accurate: precise, smooth and intricate jewelry is not an issue for jewelry 3D printers, some able to print with below 10-micron accuracy to capture your ring’s most delicate and beautiful features.

- Repeatable and scalable: 3D printers for jewelry can create potentially dozens of identical or customized ring molds at once, perfect for scalable jewelry production.

Further on the saving you money point, this is a video showing how a low-cost Elegoo 3D printer can print accurate enough jewelry wax molds to then cast in gold:

FAQs

Can You Make Gold Jewelry With a 3D Printer?

Though you can’t print gold directly on a consumer-grade 3D printer (some professional printers can, but the process is complex and expensive), standard 3D printers can produce wax or castable resin models that are then used to create plaster molds.

The wax is burnt out from the molds and replaced with molten gold to create gold jewelry. Though the process remains the same, it’s the creation of complex and bespoke molds that is now much easier thanks to 3D printing.

Can a 3D Printer Print Wax?

Yes, you can 3D print wax to create casts and molds to bring to lift complex and intricate parts during the casting process. But, nowadays, it’s more common to find hybrid materials like castable resin, which are a little more durable and tougher than wax, but burn off during the casting process just as well.

Which 3D printer is best for Jewellery?

For the highest quality detail and features, the Phrozen Sonic Mini 8K is one of the best jewelry making 3D printers on the market today. For those looking to batch print larger quantities of jewelry, Anycubic’s M3 Plus and Max offer generously-sized build volumes while maintaining excellent detail and precision.

Related articles you may be interested in: