Industrial 3D printers are increasingly replacing injection molding and other processes like CNC milling as the go-to option for small production runs and rapid prototyping. 3D printers can create incredibly detailed and intricate parts as well as full-size models, making them perfect for prototypes and high-quality part production.

- Note: you may instead be looking for our ranking of the most valuable 3D printing companies.

|

|

|

|

|

$3750

|

$10800

|

$7499

|

|

|

|

How much does an industrial 3D printer cost?

Industrial 3D printer price really depends on the quality and type of 3D printer you’re using, and what you’re planning to produce or prototype.

There are resin 3D printers such as the Formlabs 3 that sell for $3,499 that can print industrial quality pieces in sectors such as dentistry, education, medical, and jewelry, and other printers such as the Ultimaker S3 and S5, Makerbot Method, Intamsys Funmat HT, and others that cover the prosumer 3D printer market.

Beyond this, there are machines costing between $10,000 to $100,000, such as FDM 3D printers like the BigRep Studio, and Markforged’s Metal X metal 3D printer, and premium industrial 3D printers such as those sold by EOS, Carbon 3D and Desktop Metal that can cost hundreds of thousands of dollars.

We have recommended lower-end industrial 3D printers starting from the $3,000-$6,000 range, as well as higher-priced commercial machines.

How to decide which industrial 3D printer to buy?

There are several factors to consider, most notably:

- Size: consider both the industrial 3D printer’s size in terms of build volume (maximum size of parts you can print), and the total area the printer encompasses. You may not have the space to store the printer, or need the extra build volume.

- 3D printing technology: there are a range of technologies within 3D printing, which we explain in our free 3D printing eBook. Do you prioritize cheap part printing, or extremely detailed surface quality? These will determine which technology you need, and therefore which industrial 3D printer to buy.

- Materials to print: are you looking to 3D print polymers like PLA, ABS or Nylon? If so, you have options between FDM (all 3), or SLS (Nylon). If you’re looking to 3D print metal materials such as aluminum or titanium, you’ll have to buy a DMLS, EBM, Binder Jetting or other type of metal 3D printer.

- Speed: some types of 3D printers print much faster than others, even within the same technology. DLP 3D printing is typically faster than SLA, and delta 3D printers are almost always faster than Cartesians.

- Does it require a trained operator: expensive, complex and high-quality industrial 3D printers often require a skilled operator to ensure the printing process goes smoothly and the correct temperatures are maintained. This adds to costs but may be necessary for your prototyping, and is something to keep in mind.

- Resolution: different 3D printers have different levels of accuracy, precision and resolution. Resin 3D printers are more accurate than FDM 3D printers, and material jetting printers have some of the highest resolutions of any industrial 3D printer available on the market today.

- Ability to print full color: some 3D printing technologies are limited to a single color based on the metal / polymer powder, filament or resin, whereas some can print in full color such as Binder Jetting and Multi Jet Fusion.

The best industrial 3D printers we recommend

Based on our advice and criteria, here are some of the industrial 3D printers we recommend. Where possible we have provided options that are affordable to small and medium-sized businesses that do not run into the hundreds of thousands of dollars.

Raise3D Pro2 Plus — Great affordable yet large industrial 3D printer

- Build volume: 305 x 305 x 605 mm

- Price: $5,999 — Available on Dynamism Store here / Available at Matterhackers here

Pros

Reliable, accurate, and versatile.

Has an industrial build plate to prevent warping.

The 7-inch touchscreen features a very ergonomic UI.

Maximum temperature of 300°C.

Cons

More expensive than alternatives offering similar specs.

Raise3D offer both the Pro2 and the Pro2 Plus as industrial FDM 3D printers offering fantastic reliability, accuracy and versatility – with the Pro2 Plus offering a larger 605 mm Z-axis for tall parts compared with the Pro2’s 300mm.

The printer can print with 100-micron resolution, has an industrial build plate to prevent part warping, and a fully enclosed chamber to keep printing conditions consistent. The dual extruder allows for multi-material printing, such as for supports or for any rapid prototyping that requires two different colors.

The 7-inch touchscreen features a very ergonomic UI and provides useful on-screen visualizations during printing. Moreover, if you do have any problems Raise3D has US-based tech support to provide solutions.

The maximum temperature of 300°C creates a lot of opportunities for filament printing; the Raise3D Pro2 Plus can print not only standard 3D printer filaments like ABS, PLA, PETG, Nylon, but also carbon fiber infused, metal-filled, and glass-infused filaments. You can connect wirelessly using IdeaMaker – Raise3D’s 3D slicer software – to control and monitor printing remotely.

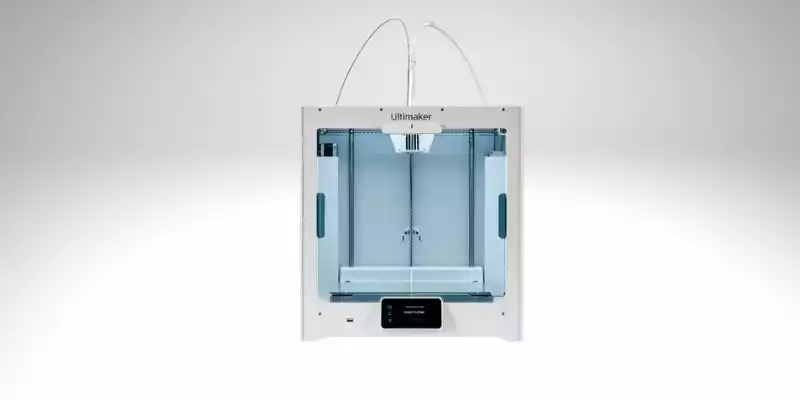

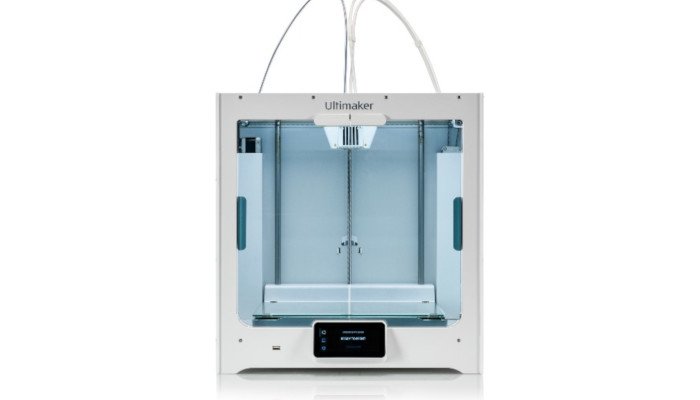

Ultimaker S5 & S5 Pro Bundle

- Industrial 3D printer build volume: 330 x 240 x 300 mm

- Price: $5,499 for the S5, $9,000 for S5 Pro Bundle — Available on Dynamism Store here / Available on Matterhackers here

- Weight: 20.6kg

Pros

Incredibly accurate and intricate prototypes and parts can be printed.

Can print high-strength glass and carbon fiber filaments.

The 4.7-inch touchscreen is easy to use.

Cons

Expensive: some may still prefer the S3 to save $2,000.

Ultimaker staked their claim as kings of the prosumer 3D printer market with the Ultimaker 3, winning awards and reaching new heights of success. The S5 was a step up into a higher price bracket, featuring a number of key upgrades and even better print quality.

Costing $5,499, the Ultimaker S5 moves up into the industrial FDM 3D printer price range, but that gets you up to 20-micron layer resolution. Incredibly accurate and intricate prototypes and parts can be printed to test functionality and shape, with partners including VW, Siemens, L’Oreal and Ford clearly seeing benefits to their production by using Ultimaker 3D printers. It can even print high-strength glass and carbon fiber filaments, with the latter especially having key applications in strong prototype and part production.

The 4.7-inch touchscreen is easy to use and has won design awards, and you can print with Ultimaker filaments or any third party 2.85mm filament — the S5 features an open filament system. Some architects have used the Ultimaker combined with a Palette to create multi-color architectural model prototypes.

Ultimaker also sells the Ultimaker S5 Pro Bundle, featuring an S5 as well as an Air Manager that goes on top of the printer that captures 95% of ultra-fine particles, and a Material Station that goes underneath the printer. The Material Station can hold up to six filament spools and can automatically switch between each one dependent on what material or color you need to use.

This allows for far more scalable and continuous printing — Ultimaker sells it as a 24/7 productivity feature. The S5 Pro Bundle costs around $9,000, and is one of the most highly regarded industrial FDM 3D printers around.

Formlabs Form 3 — best affordable industrial resin 3D printer

- Build volume: 145 x 145 x 185 mm

- Price: $3,499 — Available on Dynamism Store here

- Weight: 17.5kg

Pros

Uses LFS to provide high-quality, precise, and crisp surface finish parts.

Great for the dental, medical, and jewelry industries.

Ideal for really precise prototypes.

Cons

Small build area – so less suited for larger models such as for architectural mockups.

The Form 2 was already a mainstay in dental 3D printing, medical device printing and in 3D printed jewelry, and the Form 3 expands on this further with several key upgrades.

It uses Low Force Stereolithography (LFS) to provide extremely high quality, precise (up to 25-micron XY resolution), and crisp surface finish prints that are clear and accurate. And for those looking for a resin 3D printer with a larger build volume, Formlabs also sell the Form 3L, featuring a far larger 335 x 200 x 300 mm build volume.

No FDM 3D printer will be able to match the smooth surface area of a Formlabs resin print, making the Form 3 ideal for really precise prototypes – Formlabs show an example of 3D printed glasses on their site – as well as for intricate pieces like jewelry and dental parts, or custom pieces like hearing aids.

Intamsys Funmat HT Enhanced — entry-level industrial PEEK 3D printer

- Price: $7,499 — Available on Matterhackers here

- Build volume: 260 x 260 x 260 mm

Pros

Two interchangeable hot ends.

Versatile not just as an industrial or abrasive filament 3D printer, but also as an accurate 3D printer for more standard filaments.

50-micron minimum layer thickness.

Low price and effective.

Cons

Can be difficult to upgrade.

No WiFi connectivity.

The Intamsys Funmat HT has two interchangeable hot ends depending on whether you want to print standard filaments like PLA and ABS, or industrial 3D printer filaments like PEEK and ULTEM. This makes it versatile not just as an industrial or abrasive filament 3D printer, but also as an accurate 3D printer for more standard filaments for everyday rapid prototyping.

Read more: the best PEEK 3D printers

With a 50-micron minimum layer thickness, small businesses and industrial clients will have no problem printing accurate PEEK, Nylon, or other material parts. The Intamsys Funmat HT offers a great alternative to using 3D printing services to 3D print PEEK and other industrial filaments, costing around $6,000, far less than previous industrial PEEK 3D printers.

The Funmat HT’s low price and effectiveness has seen it used to 3D print aerospace, automotive, engineering, and medical sector parts. It is also used in general R&D, and overall is considered a great 3D printer, offering industrial 3D printing on a smaller scale and the 3D printing of the toughest filaments around, at far more affordable prices.

Sinterit Lisa — Entry-level industrial 3D printer using SLS

- Build volume: 110 x 150 x 150 mm (For TPU)

- 90 x 130 x 130 mm (for Nylon/PA)

- Price: €7,999

- Weight: 41kg

Pros

One of the lowest cost industrial SLS 3D printers.

Precisely designed calibration and testing procedure.

Don’t need print support, saving time and money on powder.

Sinterit has their own dedicated software and sells accessories.

Cons

Small build volume.

The Sinterit Lisa is one of the lowest cost industrial SLS 3D printers around, bringing all the main advantages of selective laser sintering but without the price tag. Made in Poland, every machine passes a “precisely designed calibration and testing procedure” according to Sinterit.

The main advantage of SLS 3D printing is that you don’t need to print supports, saving time and money on powder. You can also print multiple parts concurrently in the build platform, and so is perfect for businesses printing multiple parts at once, or printing many similar parts that are slightly different to test which prototype is best. The Sinterit Lisa can perform all these functions with ease with its 0.05mm X and Y axis accuracy, and up to 0.075mm Z-axis precision.

Sinterit have designed their own dedicated software, and sell accessories including the Sandblaster as well as specialized SLS powder materials. You can control and print via the Sinterit Lisa’s 4-inch touchscreen, as well as by WiFi or USB.

Desktop Metal Fiber — Most affordable industrial metal 3D printing machine

- Price: Requires a Quote — Available at Dynamism here

- Build volume: 310 x 240 x 270 mm

Pros

Far lower priced than other metal industrial printers.

Parts that can withstand up to 250C temperatures.

Decent build area.

Cons

Hard to find and get one.

Desktop Metal, now a public company and who recently acquired EnvisionTEC in a $300m deal, offer one of the most affordable ways to get into industrial metal 3D printing. The Desktop Metal Fiber System can print PEKK, PEEK, or Nylon with continuous carbon fibers or fiberglass to greatly improve part strength.

The Fiber System is still an industrial 3D printing machine, but is far lower priced than previous metal printers. It combines FDM-style filaments with metal, using their new Micro Automated Fiber Placement technology with continuous carbon fibers. Rather than purchasing it outright, Desktop Metal offer leasing options with a yearly subscription, saving smaller businesses upfront costs and making it easier to get started.

Read more: metal 3D printer buyer’s guide

The Fiber mixes these already tough materials like PEEK with carbon fibers, creating astonishing strong — yet lighter than aluminum — parts that can withstand up to 250C temperatures. For a metal 3D printer the build area is also not bad, especially considering the low price compared with most industrial DMLS 3D printers.

Markforged Metal X — Accessible industrial 3D printing metal

- Price: $100,00

- Build volume: 300 x 220 x 180 mm

Pros

Reliable and accessible.

Can print materials like copper, Inconel, A2 and D2 steel, and 17-4 PH stainless steel.

Cons

Expensive.

Markforged’s Metal X 3D printer is one of the most accessible ways to 3D print metal, a very viable alternative when compared with possibly spending hundreds of thousands of dollars on a DMLS or EBM 3D printer.

Using Markforged’s bound powder filament technique, you can print with materials like copper, Inconel, A2 and D2 tool steel, and 17-4 PH stainless steel. The Metal X combines FDM-style filament printing with metal, not too dissimilarly to how Desktop Metal have. This makes for a more accessible way to 3D print metal, either for in-house part production and prototyping, or as a service creating reasonable-sized metal parts.

Why use an industrial 3D printer?

Industrial 3D printers are used for rapid prototyping in tandem with 3D CAD software for product design (although occasionally CNC machines are used instead).

3D printers can quickly print small-scale versions of final products to test the design or functionality, with any mistakes able to be instantly changed by editing the 3D model and re-printing the next iteration for testing. Rapid prototyping is frequently used in the aerospace, automotive, and medical sectors.

Since 3D printing is a form of additive manufacturing, there is no waste from removed materials such as with CNC machines. This makes industrial 3D printing very valuable in industries where saving on expensive materials is important, such as metal 3D printing. 3D printers can also create parts with differing infill percentages, leading to lighter yet still very strong metal parts — extremely valuable in the automotive and aerospace sectors where cutting weight can noticeably increase profit margins.

Some other articles you may be interested in: