How Medical 3D Printing Could Save Millions of Lives

At 3DSourced we’ve covered everything 3D printing and 3D since 2017. Our team has interviewed the most innovative 3D printing experts, tested and reviewed more than 20 of the most popular 3D printers and 3D scanners to give our honest recommendations, and written more than 500 3D printing guides over the last 5 years.

Recent advancements in medical 3D printing offer potentially revolutionary and life-saving breakthroughs. And what’s more, the technology could be widespread within the very near future.

The private healthcare market in the USA has incentivized research into 3D printed medical technologies; in 2018, according to Allied Market Research, the 3D printing in healthcare industry was worth $973 million and is expected to reach $3.7 billion by 2026 and $8.1 billion by 2029.

With the potential for 3D printing to be at the forefront of cutting-edge medical technology, saving and bettering thousands of lives in the process, here is our feature on the exciting world of medical 3D printing.

Part 1: Why Doctors Trust Medical 3D Printing

In almost every area tested, 3D printing has shown noticeable improvements for doctors and patient outcomes. For this reason, medical professionals from around the world are embracing medical 3D printing as the future of the field.

It is clear to see that 3D printing in medicine has a lot to offer, and not just in terms of theory. In 2017, a study by the National Centre for Biotechnology Information examined thousands of clinical trials of 3D printed medical devices in patients. Of the 350 that met their criteria, they concluded that all medical fields that assessed 3D printed medical devices reported that they were effective and outperformed other methods. The main benefits were decreased surgery time and increased accuracy.

Whether using CAD software for 3D imaging and modeling, or by physical manufacturing, 3D technology has been benefitting patients for decades.

In the 1990s, the first 3D printed dental implants were constructed, marking the first instance of 3D printing in medicine.

In the surgical field, anatomical modeling for bone reconstruction was an early indicator of what the technology had to offer, with surgical implants being a natural result.

In 2001, the first 3D printed medical scaffold was developed, used to grow a human bladder. In 2008, the first 3D printed prosthetic leg was manufactured and in 2012, LayerWise created the first 3D printed human jaw.

From there, the medical applications for 3D printing have exploded, and become an integral part of treating countless conditions, from heart disease to cancer and beyond. And the limits of what is believed to be possible are constantly being pushed by visionaries in the field.

Chuck Hull, the inventor of the first 3D printer, has stated that even he is surprised at the medial applications of his creation, a usage he never envisioned: “To me, some of the medical applications [have been the most surprising]. I didn’t anticipate that, and as soon as I started working with some of the medical imaging people, it became pretty clear that this was going to work.”

It is easy to understand why industry professionals, and the general public, are excited about what medical 3D printing could mean for the future of healthcare. With the aid of computers, there is freedom to personalize care down to a microscopic level.

Researchers at the National Institute of Standards and Technology announced in September 2020 that they have been able to 3D print gel structures for pharmaceuticals as small as 100 nanometers, 1,000 times smaller than a human hair. By refining their methods, they expect to half that again.

While they were careful to state that more investigation needs to be done before medical 3D printing becomes standard practice, these cases show positive early signs.

Part 2: How 3D Printed Medical Devices Are Being Used Now

3D printed organs and tissue

Heart disease is the leading cause of death globally, according to the World Health Organisation, similarly to the United States, where heart disease deaths are nearly 400% higher than accidents, the third largest cause. Researchers are exploring 3D printing as a potential solution to this problem.

- We also have a full feature story on 3D printed organs and bioprinting.

- We also have a feature story on 3D printed hearts.

There are multiple ways in which medical researchers can use 3D printing to manufacture tissue samples and even entire organs. Ill patients can be given a new lease on life with 3D technology.

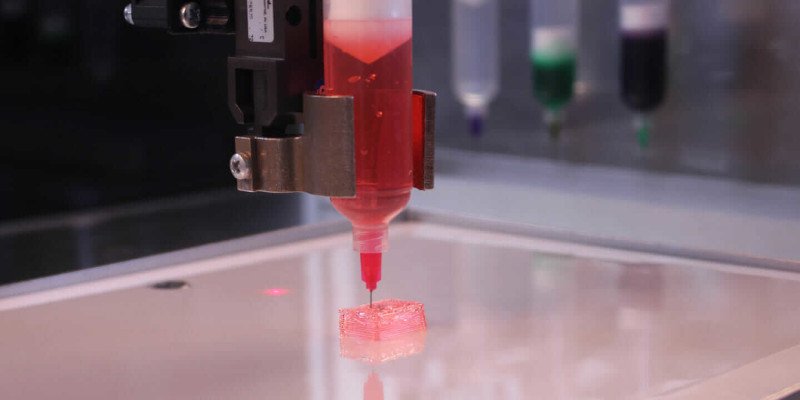

Bioprinting is often referred to as medical 3D printing. Since its inception in 2003, bioprinting has developed significantly to the point where intricate and complex bodily structures could soon be entirely 3D printed.

The process involves growing a biopsied tissue sample around a 3D printed mesh or scaffold, specifically tailored to the patient’s anatomy using CAD software. Previously, replacing damaged tissue was limited to a transplant, but now scientists can grow bodily structures with the patient’s own cells.

Within the printer, cartridges of cells and nutrient fluids are fed through the nozzle, or multiple nozzles depending on the complexity of the structure being printed, and molded around the scaffold. Once the printing is complete, the structure is Crosslinked, meaning it is treated with an ionic solution or under ultraviolet light.

It is then placed in an incubator to cultivate, eventually developing to a level where it can be surgically implanted into the patient’s body.

To date, only tissue samples have been reliably produced, but progress towards more significant advancements appears to be right around the corner. In 2019, researchers at Tel Aviv University’s School of Molecular Cell Biology and Biotechnology were able to grow a functioning heart completely out of human cells. While only the size of a rabbit heart, it no doubt proves the concept of 3D printed hearts and marks a huge step towards curing heart disease.

And it doesn’t stop there. Experts say that there is nothing to stop the printing of other organs such as liver, kidneys and even skin using this method, all of which have been successfully trialed, curing a range of fatal conditions and starkly reducing transplant waiting lists.

Prosthetics

Using 3D printing, doctors can custom produce prosthetic limbs for victims of accidents, military veterans and children born with disabilities, making production far faster, better fitting and much cheaper.

- We also have a feature article on 3D printed prosthetics

What’s more, the relative ease of production means that children can receive multiple limbs as they grow up to fit their developing needs, all of which can be produced quickly and cheaply. The main issue with prosthetic arms for children is that they become obsolete within a year, making the expense simply not worth it for all but the most affluent. Far cheaper 3D printed prosthetics offer a fast and effective solution for children with limb deficiencies.

With 3D printed medical techniques, a standard plastic prosthesis can be produced for as little as $30, as pioneered by E-Nable. Additionally, American company Limbitless Solutions has been able to reduce the cost of a myoelectric arm – one that connects to your nervous system and moves based on electrical signals from your existing muscles – from over $10,000 to as little as $1,000.

Industrial design student William Root also developed a titanium 3D printed prosthetic leg using 3D printing back in 2015, which more closely resembles the real limb than traditional models, improving both comfort and balance.

3D printed orthopedics

There are more than 450,000 hip replacements annually in the US, and traditional methods for constructing metal joints can be very expensive as metal is hard to melt and reform. In addition, these replacement joints often degrade and destroy the surrounding tissue, leading researchers to find alternative methods, and 3D printed implants look promising.

Polyetheretherketone (PEEK) is an industrial, durable plastic used in 3D printed implants for bone reconstructions, with the medical community recognising its chemical resistance, light weight, high-temperature performance and durability, as well as being easy to adapt to specific patients.

3D printed orthopedics are also extremely useful in improving recovery time from significant bone surgeries and injuries. Much like with other applications, joints, bone segments, or even entire bone structures, can be 3D printed and implanted.

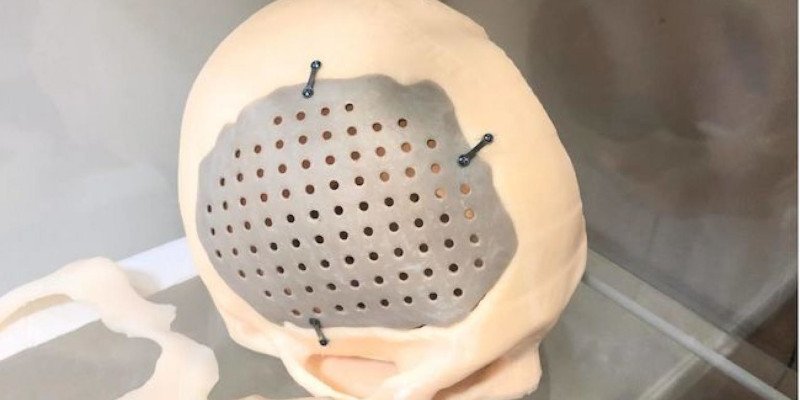

For more traumatic injuries, surgeons have been able to use medical 3D printing to help with bone regrowth and reconstruction. In 2014, Stephen Power from Cardiff, Wales, who had been in a serious motorcycle accident, had large portions of his face and skull replaced with 3D printed bone to great success.

After scanning his head and digitally reproducing his injuries, doctors then 3D printed titanium plates for his skull, cheek and jaw and fixed them during an 8-hour surgery, the first of its kind in the world. The technique produced much more precise results, leading to a better outcome, with the increased efficiency in production resulting in a lower cost than other methods.

As well as costs, we have already seen reduced rates of replacement for elective implants, and drastically reduced recovery times, which point to the positive impact medical 3D printing is having on the industry.

3D printed surgical instruments

Surgical implements are key to surgical accuracy. To reduce costs for manufacturers, surgical tools such as scalpels, clamps and forceps are mass produced with a ‘one size fits all’ approach. This does not consider the technique or surgeon’s preferences and can make it difficult for them to perform lengthy procedures.

3D printing is already becoming a game changer in this field, able to print custom instrument handles tailored to a surgeon to make them more ergonomic. This has led to a distinct increase in surgical accuracy, and the tools themselves can now be manufactured using sterilizable materials, making them safe and durable.

On top of this, being able to 3D print blades and chisels for example has improved the efficiency of certain procedures. Endocon GmbH, a German medical device company, had produced a 3D printed tool for hip cup replacements, with those who have used it reporting radically reduced surgery time and a tenfold drop in rejection rate.

Surgical Phantoms

Surgical phantoms are perhaps the most advanced 3D printing medical techniques currently in operation. Using 3D modeling software, surgeons can replicate a patient’s internal structure, be it bones, nerves, organs, or blood vessels, and reproduce it.

Whether it is a digital image, or printing a physical replica, doctors can now analyze a patient’s unique anatomy and devise a plan ahead of a procedure, further reducing surgical time. By 3D printing a physical copy, they are even able to practice their technique and visualize the procedure.

The television show Grey’s Anatomy demonstrated how useful this can be. In one episode, the doctors were able to print a life size model of a tumor, mapping where it interacted with surrounding tissue and identifying how to remove it.

This technique can be applied to a range of different scenarios and will allow doctors to decide upon treatment methods with increased accuracy.

Part 3: 3D Printed Medicine: Pharmaceutical 3D Printing

There are, in fact, far more applications for medical 3D printing than just those in the surgical field. An emerging market is that of pharmaceutical 3D printing.

In 2017, GlaxoSmithKline tested the efficacy of Inkjet printing and ultraviolet curing in the production of tablets to treat Parkinson’s Disease, showing positive results. Through such methods, manufacturers have been able to increase the potency of the drugs they produce, which would not have been possible through other methods.

This has led pharmaceutical manufacturers to pursue 3D printing to produce customized medications for patients. Now, dependent on someone’s specific condition, medication can be made more targeted and effective, with tailored levels of different medicines for each individual. This personalization would also result in fewer side effects from generic formulations and improve patient compliance.

On a more consumer-based level, the private market has allowed for new companies to emerge, selling customizable vitamins and supplements for everyday use.

In 2019, Dragon’s Den, the UK’s equivalent of Shark Tank, featured a pitch from VitaMYne, a company providing a home-delivery service where consumers could order bespoke 3D printed vitamins, composed from a custom selection of 27 ingredients. This suggests custom 3D printed medicines are likely to become far more widely used soon.

Part 4: Could There Be Heartbreak for 3D Printing in Medicine?

With so much progress having already been made in the field of 3D printed medicine, what are we likely to see in the near future?

Firstly, prototypes of a 3D printed electronic pill are being tested, with the patient able to control their own dosage, helpful for use with painkillers. Once ingested, the patient can control the release of drugs using the Bluetooth on their phone.

However, medical 3D printing has its drawbacks. Inkjet printing – the main technique used for 3D printed drug production – requires expensive and rare materials. Additionally, 3D printing medicines are not yet reliable and high quality enough to safely mass produce. With catastrophic consequences for even small defects, the technique still needs refining.

However, despite all of this, looking at the bigger picture is important. 3D printing in medicine shows the potential to helping millions around the world, with safer medical models improving surgery results, more effective medical implements, and cheaper, better fitting prosthetics.

We all dream of a world where disease is a thing of the past, and medical 3D printing is the largest leap towards that goal we have taken in decades. Maybe, it might not be a dream for long.