3D Printed Liver: Everything You Need to Know

At 3DSourced we’ve covered everything 3D printing and 3D since 2017. Our team has interviewed the most innovative 3D printing experts, tested and reviewed more than 20 of the most popular 3D printers and 3D scanners to give our honest recommendations, and written more than 500 3D printing guides over the last 5 years.

Since being invented in the 1980s, 3D printing has evolved into a catalyst for potential and innovation. Adapting to multiple industries, it’s been used for everything from printing vegan meat to 3D printed homes.

But today, we’re going to discuss printing that hits closer to home and that’s 3D printed organs, more specifically, 3D printed livers. This science brings a wealth of opportunities to the medical industry that could lead to drastic positive changes in how future transplants and organ diseases are treated.

In this article, we’ll cover what a 3D printed liver is, how to bioprint a liver, and the scientific discoveries currently leading this industry.

- See also: Our feature story on 3D printed houses.

- For more on bioprinting: our complete guide to 3D bioprinting organs.

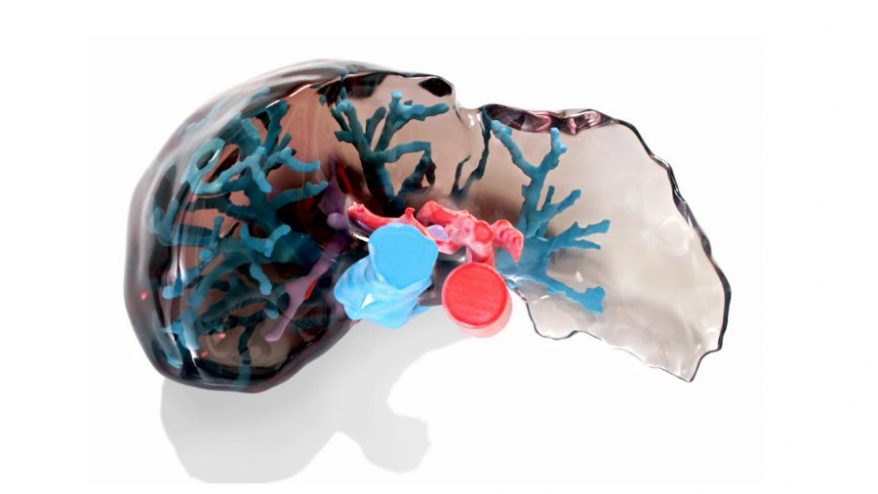

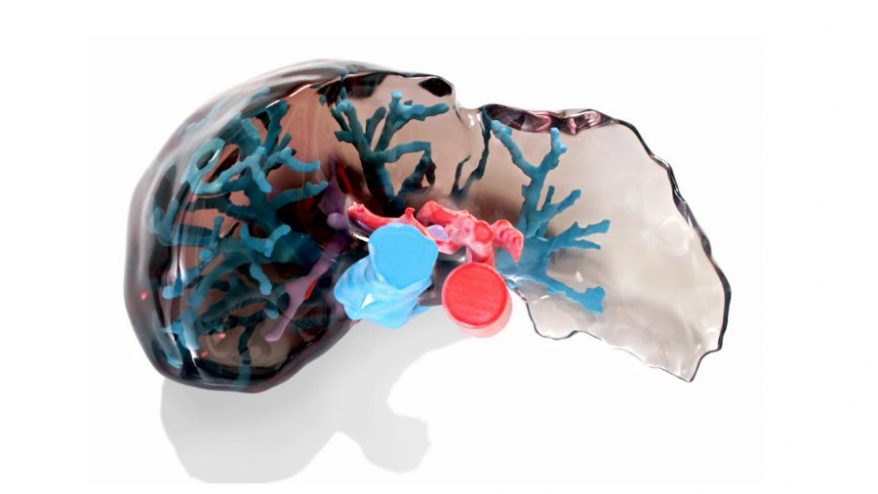

What Is a 3D Printed Liver?

A 3D printed liver is well… a liver created through 3D printing. However, instead of simply printing an object shaped like a liver, scientists are using bioprinting to create a liver using a patient’s own cells.

Your liver is a filter for your body that constantly processes the toxins and nutrients in your blood and diet, breaking them down. Creating a 3D printable liver that contains all the necessary vascular intricacies and that can perform the acts above is complicated, but recent studies look promising.

3D bioprinting livers are only the beginning as many organs, like the heart, are getting the bioprint treatment as scientists work to create transplantable tissues and organs from scratch.

Now, the liver isn’t perfected yet, but sizeable growth is happening.

See also: If you want to learn more about 3D printed hearts, check out our complete guide.

Using 3D Bioprinting to 3D Print Livers

Bioprinting is the technology that’s currently making this dream a reality.

Much like normal 3D printing, it uses a moldable substance to create 3D objects, but instead of plastic or other traditional materials, it uses a blend of bioink and biopolymer gel to create a hydrogel.

Think of bioink as the pigment and biopolymer gel as the plastic.

Bioink is made up of cells, and when bioprinting, the bioink uses the patient’s cells. That way the liver is an exact genetic match, and you can avoid transplant complications like rejection.

Biopolymer gel is the molecular scaffold that keeps the structure stable, and together they create a living material.

As it’s printed, it’s cryogenically frozen with carbon dioxide to solidify it into shape. To keep the cells alive throughout this process, the hydrogel maintains a liveable environment for the cells or an extracellular matrix.

When using a printed organ for human use, it has to have living functioning cells. Bioprinting is what makes that possible.

Industry Leaders

With an expected industry value of $1.95 billion by 2025, it’s no surprise that being the first to create a functioning printed liver is a huge motivation in multiple countries.

In a race to see who can monopolize this industry first, we’re greeted with back-breaking effort all over the world. However, only a few possess the ingenuity to lead this race.

University of California Breakthrough

In 2016, in San Diego at the University of California, Dr. Shaochen Chen, a nanoengineering professor, 3D printed liver tissues that mimicked the liver’s structure and actions. It perfectly matched a real liver when examined under a microscope.

Stem cells harvested from the skin were combined with endothelial and mesenchymal cells and turned into liver cells. Endothelial cells are a single cell layer that lines blood vessels and helps develop connective tissue cells. Mesenchymal cells are bone marrow stem cells.

Stem cells are unique because they have the ability to become any type of cell. Skin, heart, blood, or liver, they’re the stem of all cells.

The tissue printing happened in two phases. Printed first was a honeycomb pattern of 900-micrometer-sized hexagons containing the stem-turned-liver cells. Then the supporting endothelial and mesenchymal cells were printed in between the hexagons.

The cells were printed on 3 x 3 mm squares, 200 micrometers thick, and sat to develop for 20 days.

Testing showed these samples sustained higher levels of enzymes necessary for the liver to metabolize many drugs.

When asked about the future of these tissue samples, Dr. Chen stated:

“I think that this will serve as a great drug screening tool for pharmaceutical companies and that our 3D bioprinting technology opens the door for patient-specific organ printing in the future.”

Dr. Shaochen Chen

Organovo’s 3D Printed Liver Tissues

Credited with setting the industry standard with the ExVive kidney and liver tissue and creating separate capillary blood networks that mimic the body’s function, pioneers Organovo are leading the race in California.

Following their ExVive success, and a multi-year deal with pharma giant Merck, they’ve begun working on clinical trials and developing 3D bioprinted liver tissue transplants.

Tremendous progress aside, bioprinting full-sized livers to help the medical community save millions is not yet possible.

However, Organovo’s 3D printed tissue patches can provide immediate benefits to patients on the transplant waitlist. Representing the difference between life or death, these small but powerful dollar bill-thick patches increase survivability and offer temporary solace as they can sustain a patient by 1-2 more years while they wait for a life-saving organ transplant.

Their goal was to start using these transplants in 2020, but we hope to see them in action this year.

Brazil’s 3D Printed Liver Spheroids

Last on our world tour is Brazil.

In recent 3D bioprinting developments, researchers in Sao Paulo have created a way to bioprint miniature livers, or liver spheroids. Using human blood vessels and Cellink’s Inkcredible bioprinter, it’s said this miniature liver can carry out all the functions of a normal liver.

From collecting the volunteer sample to manipulating the stem cells and personalizing the bioink, to finally printing the end product, the entire process took 90 days. Growing the actual cell structure took 18 days.

If this liver became transplant viable, it would decrease wait times significantly.

According to Ernesto Goulart, co-author of the study, the researchers found a way to group cells together before printing, rather than printing them individually. The improved cell contact from being printed together allowed the spheroids to function for much longer.

Now, they’re working on completing this experiment on larger scale organs.

How Can 3D Printed Livers Save Lives?

There are multiple ways 3D printing saves lives. From early stages of testing to full-on transplants, 3D printable organs help speed up the medical process.

Faster and More Reliable Transplants

The main way 3D printing saves lives is through organ transplants.

30,000 people a year die from liver cancer alone. And that’s not including the dozens of other liver diseases that are equally as fatal.

Between all these diseases, thousands join an endless transplant waitlist, hoping not to become part of that statistic. Waiting for the unfortunate accident of a liver to become available, that’s free from damage and healthy, is not a reliable solution.

Then on the off chance you do get a liver transplant, there’s always the possibility of your body rejecting it because it’s a foreign object.

However, with viable 3D organs, there’s the potential to cut down wait times or at least sustain a person’s liver for longer while they wait for a transplant.

A 3D printed liver from a person’s own cells also eliminates any possibility of rejection.

Transplant rejection poses a huge threat to patients’ lives because it’s our immune response to detect foreign objects and get rid of them. But when you use a 3D printed organ made from the patient’s cells, there is no foreign object to reject, and you help the body heal itself.

Taking away that possibility of rejection increases the success rate exponentially.

Efficient Animal-Free Testing

Another benefit is more efficient testing and clinical trials.

One of the big ethical debates in the medical world is animal testing. Before human trials can take place, scientists are bound by law to test on animals first.

With 3D organs, there’s no need to test on animals because there are no “unknown” factors. If you’re using someone’s cells to create treatments for them, there’s no surprise variable. You can also create surplus organs that can be used for testing as opposed to the unethical use of animal testing.

This would allow drugs and treatments to accelerate through the clinical trial process at a rapid pace and without harming animals in the process.

Better Training

Finally, there are some incredible training benefits.

Medical school students go through rigorous coursework and hands-on training with human organs, which is dependent on donated bodies.

3D printable organs would make it easier and more ethical to source organs for students to practice on, leading to more structured training and better-skilled medical professionals on the field.

Setbacks

One of the main struggles that keep 3D printing from saving lives is function.

Livers are an intricate design of capillaries, vessels, and structures that need to be printed perfectly to stay functional. Failing to do so restricts blood flow and shortens the lifespan of the 3D organ.

The printed liver also needs to be able to filters toxins as well as many other endocrine system functions, and achieving this is incredibly difficult.

Future Expectations

The future looks bright for 3D printed livers and the involvement of 3D printing in the medical industry as a whole.

With laboratories moving onto clinical trials and the race to enter the 3D printing market, the future of medicine has the potential to evolve quicker than anticipated.

And the medical industry isn’t alone. 3D printing has gone on to change the food and fashion industry too, truly becoming the Swiss Army knife of technology.

Other articles you may be interested in: