Most standard 3D printing filaments like PLA are plastic or plastic-based, and so are naturally electrically insulating. However, with newer innovations being researched and released, conductive 3D filaments are becoming more common with new applications for them being found every day.

Conductive filaments have a variety of uses, and come in a few types and styles. Unlike most specialty filaments like ones that glow in the dark or marble PLA filaments that are blended to look like stone, conductive filaments go beyond mere aesthetics and have more practical applications.

What is Conductive Filament?

PLA and ABS are commonly blended with other materials to change their color, texture, and appearance. Many of these properties are aesthetic, but some have more useful applications.

Conductive filaments are materials that use standard 3D printing materials like PLA and ABS as a base before blending in additives like carbon and graphene to make them electrically conductive.

You won’t have much luck making a circuit board with PLA, and you’d have a hard time making a working smartwatch with normal ABS and some elbow grease. But with conductive filaments, these projects become very doable indeed.

What is Conductive Filament Used For?

As technology advances, so does its portability and, yes, even wearability. And with electrically conductive filaments, you can print working circuit boards and circuit board parts to design and model your own electronics.

On a large-scale industrial note, conductive filaments can be used for engineering repairs and even quickly-made signal-jammers to ensure privacy in short-wave radio communications for confidential broadcasts.

They can also be used in medical institutions to ensure cellular phone signals don’t interfere with important equipment. Maybe in the future, there’ll be no need to turn off your cell in the cardiology ward!

Of course, there are a lot of home-based applications for conductive filaments too.

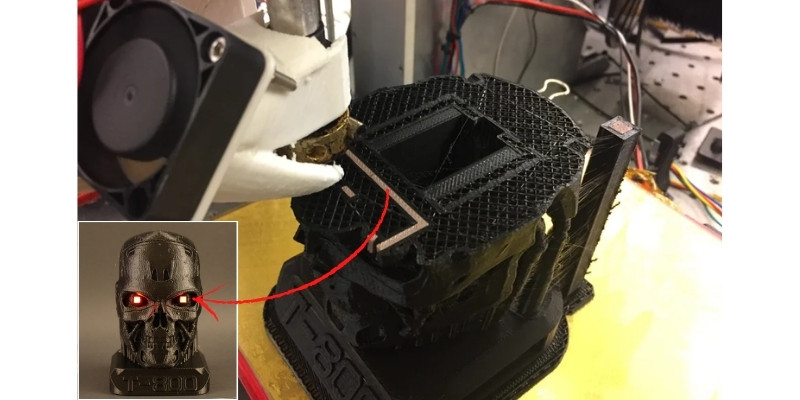

Conductive ABS can be used to make devices like touchpads, LED-lit structures, key fobs, and many other electricity-based projects that can now be done with little more than a 3D printer and some engineering know-how.

Using Conductive Filaments vs. Standard Filaments

Conductive filaments are still relatively new, but with enough trial and error, 3D printing enthusiasts have figured out some of the best settings to use.

Typically, you will need to print conductive filaments at higher temperatures than most others. This is because these filaments are usually blended with metal particles, which require more heat to melt and accurately print.

Recommended Settings For 3D Printing Conductive PLA and ABS

If you’re using conductive PLA, it’s best to have your nozzle temperatures to around 200℃, and no more than 230℃.

If you’re using conductive ABS, however, you’re better off setting your nozzle to as high as 240 – 260℃ for the ideal results.

Conductive filaments are more abrasive than most, so if you can you should use a strong metal nozzle like steel.

For all kinds of conductive filaments, setting your print speed to no more than 70mm/s is a good idea, though around 30 – 50mm/s will yield more reliable results. And if you’re using a heated bed, try to keep it at around 60℃ for the best adhesion.

If you stick to these recommendations, then you should be fine. But if you’re ever in doubt, always check the settings recommended by the manufacturer, which do differ somewhat between distributors.

Here we’ll look at some of these distributors as well as their own recommended printer settings.

What to Consider When Buying Conductive Filaments

It’s worth noting that conductive 3D printer filament will be far more expensive than standard filaments, so while we will be listing the price as being per kilogram, don’t worry! Most are available in smaller-than-average spools to help save you money.

Conductive filaments also do not give off any electricity on their own, so you will need to consider a power source. The kind of battery or power output you should go for will depend on the project you have in mind, so be sure to consider your energy source before you go purchase your filament.

It’s also worth noting that you won’t find conductive filaments in any color other than black. I’m afraid we’re still a while away from conductive rainbow PLAs.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

ProtoPasta Conductive PLA

- Price: Check price on Amazon here

- Print Speed: 20 – 80mm/s

- Recommended Nozzle Temperature: 215 – 230℃

Pros

High compatibility with most 3D printers.

Low-priced and reliable.

Can be used by just about anyone of any skill level.

Cons

Some find inconsistencies with its conductivity.

If you’ve already looked into conductive PLA, then chances are you’ve already come across ProtoPasta. It should come as no shock that it’s at the top of a lot of lists given its high compatibility with most 3D printers, relatively low price, and good reliability.

It’s easy to see why ProtoPasta’s conductive PLA has caught so much attention. It’s designed to be a versatile conductive filament that can be used by just about anyone of any skill level.

While ProtoPasta do claim that their conductive PLA can be 3D printed with the printer settings you’d use with normal PLA, we do recommend bumping up the temperature to ensure conductivity and reliable printing.

You won’t need a special nozzle or a heated bed, though, so it’s perfect if you own a budget 3D printer like the Flashforge, Creality, Anycubic, or any other standard PLA-compatible FDM printer.

Overall, ProtoPasta’s conductive PLA is ideal for those of you with less powerful 3D printers who are looking to dabble in using conductive filaments before you go full-throttle. It’s also a great choice if you have smaller projects in mind like LED lit projects or smaller, more niche electricity-based prints.

ProtoPasta has even included a link to some projects here to help you get those creative juices flowing before you add anything to your cart.

This filament is available in a variety of spool sizes, though be warned that the smallest of which – 125g – comes loose, so you may want to have your own spool ready if you’re buying in small quantities.

Amolen Conductive PLA

- Price: Check price on Amazon here

- Print Speed: 30 – 70mm/s

- Recommended Nozzle Temperature: 220 – 250℃

Pros

Highly compatible with most standard FDM 3D printers.

Minimal-to-no warping or bubbling.

High-quality prints that are hassle-free.

Cons

Does not come with a battery.

Amolen is known for specialty filaments like PLA blends, PLA filament glow-in-the-dark, and yes, even conductive PLA.

Like ProtoPasta, Amolen’s conductive PLA is highly compatible with most standard FDM 3D printers, and it’s heat bed optional, so you won’t need any special equipment to get your projects up and running.

While slightly more expensive, what you’re mainly paying for with Amolen conductive PLA is reliability. It boasts minimal-to-no warping or bubbling, making for good, high-quality prints that are hassle-free and generally easy to use.

It also comes in spool sizes from 200g, costing around $23, so it’s another conductive PLA you should go for if you’re just looking to test the waters. But like many options on this list, Amolen’s PLA does not come with a battery, so you will need to decide on your own power source even if it’s just to test it out.

Recreus Conductive Filaflex – Conductive TPU Filament

- Price: $120/kg

- Print Speed: 20mm/s

- Recommended Nozzle Temperature: 245 – 250℃

Pros

Strong and flexible.

Good versatility.

Ideal for more involved projects like wearable electronics, computer repairs and accessories, and complex circuit boards.

Cons

High price and low printing speeds.

Only suited to low-current projects.

Recreus is a Spain-based filament manufacturer that specializes in ‘out-there’ filaments, and one of their coolest is their Conductive Filaflex.

If the price and printing speeds shocked you, don’t worry, there is an explanation. Recreus’ flagship conductive filament is TPU, which is known for having a much higher tensile strength than PLA, making it ideal for more involved projects like wearable electronics, computer repairs and accessories, and complex circuit boards.

Despite its strength, this conductive TPU is also highly flexible, meaning you won’t have to alter any complex designs to accommodate rigid elements. Essentially, this is a tough and versatile conductive filament that’s best suited to those of you who have already turned a hand to electrical engineering.

This recommendation for seasoned builders is backed up by the fact that Recreus only sells their conductive TPU from 500g (costing around $60), so newcomers or those just looking to dip a toe in printing with conductive filaments may find themselves spending more than they need to.

Despite its versatility, the Conductive Filaflex is still only really suited to low-current projects. Those of you looking to light up your homes or power your cars will need to look elsewhere.

Vilarox Conductive ABS – Best Conductive ABS Filament

- Price: Check price on Amazon here

- Print Speed: 30 – 70mm/s

- Recommended Nozzle Temperature: 220 – 260℃

Pros

Highly compatible.

More flexible than PLA and TPU.

Vilarox is confident that this filament will work with all FDM printers.

Cons

More brittle than TPU and PLA.

Prone to warping.

Speaking of flexibility, Vilarox offers up the best conductive ABS on the market today. It’s highly compatible, with Vilarox claiming that their testing has made them confident that this filament will work with all FDM printers.

Like normal ABS, Vilarox’s conductive filament is more flexible than PLA and TPU, but it is a lot more brittle. This means that, while it is ideal for making basic electronics like circuit boards and simple LED strips, it’s not great for things like touchpads or wearable electronics that are designed to be moved around and withstand the elements.

That being said, it is a popular filament for smaller electrical engineering projects, and promises to be of great use to anyone looking to make smaller, static prints that make use of its conductivity.

Like the Recreus conductive TPU, it’s only sold in 500g batches, which means it is recommended that you use caution when adding it to your cart, as those of you only looking to dabble in smaller projects may find yourself needlessly out of pocket.

Please note that ABS is also more prone to warping than PLA, so it’s better used with an enclosed printing space to avoid outside variables from misshaping the prints. We also recommend a heated print bed at around 50 – 80℃ to help with bed adhesion to assure more reliable results.

This does mean that those of you with lesser-equipped printers are more likely to run into issues when printing with conductive ABS, so you may want to stick to conductive PLAs for more reliable prints.

Related posts: