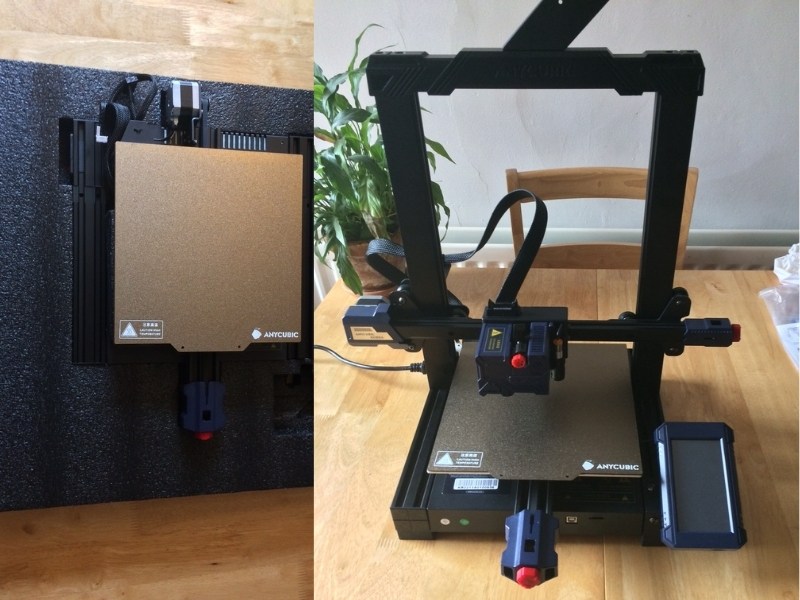

Anycubic’s FDM line-up swelled this year with three scaly new additions, all bearing the Kobra name and looking like an unnested set of Russian dolls when lined up side by side.

Despite these surface similarities, there’s quite a lot separating these misspelled serpents, not just the more apparent build volume bump on the Plus and Max.

For beginners, I’d recommend the standard Anycubic Kobra. It is the smallest and most affordable option, and a good choice for makers on a budget who need a compact printer that is easy to use.

For increased functionality, the Anycubic Kobra Plush adds features like automatic bed leveling and filament run-out detection. It sits in the goldilocks spot between the standard Kobra and Kobra Max in terms of price and build volume.

The Anycubic Kobra Max is the largest and most expensive option, with a massive build volume of 400 x 400 x 450 mm. It has the same features as the Kobra Plus but with a larger, sturdier frame.

Having tested and reviewed the Anycubic Kobra to compare it against its bigger brothers, here’s my comprehensive Anycubic Kobra vs Kobra Plus vs Kobra Max comparison guide.

Anycubic Kobra vs Kobra Plus vs Kobra Max: Meet The Printers

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

BUDGET PICK

Anycubic Kobra

Available at:

MID-RANGE PICK

Anycubic Kobra Plus

Available at:

HUGE PRINTER

Anycubic Kobra Max

Available at:

Anycubic Kobra

Pros

A solid choice for makers on a budget.

Automatic mesh bed leveling, a direct drive extruder, and more for under $300.

Hassle-free printing.

Cons

Smallest of the Anycubic Kobra printers.

The smallest of the bunch, the Anycubic Kobra is a compact, low-cost 3D printer that punches well above its weight and makes a solid claim as the first choice for makers on a budget.

For under $300, Anycubic has bundled in automatic mesh bed leveling, a direct drive extruder, a sleek PEI-coated removable build surface, and sensorless homing. The feature set is so beyond what we’d expect at this price point that a double-take is required to ensure we aren’t eyeing up a printer twice the price.

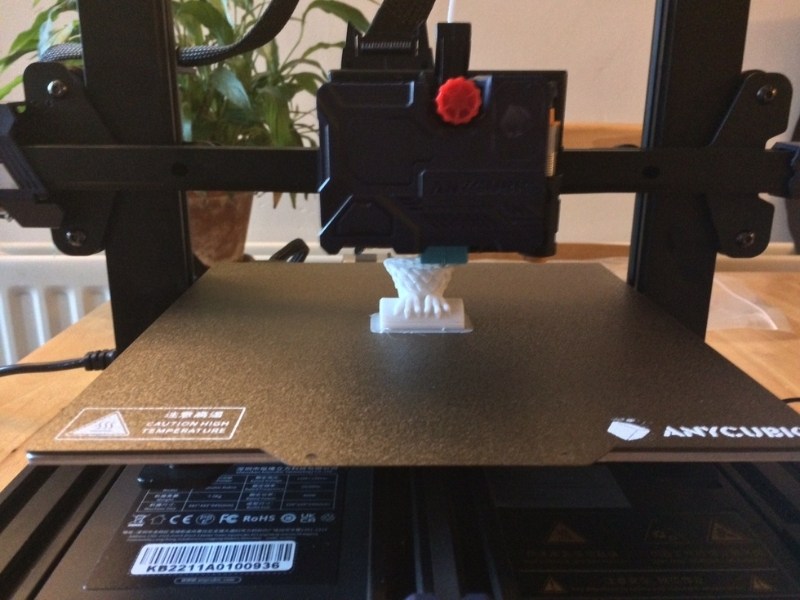

Specifications aside, we had some quality hands-on time with the Anycubic Kobra and found it offered a streamlined, largely hassle-free printing. And, with a little nurturing and software tweaks, it reliably churns out impressive quality prints for the price.

Corners have been cut – unavoidable in this price range – with plastic casing throughout, but Anycubic went about it smartly to minimize the impact on print quality and the overall experience.

Anycubic Kobra Plus

Pros

Geared for versatility.

Rival the Creality CR10 at a competitive price.

Borrows the same great features from the Kobra.

Cons

Drafts in a carborundum glass build plate, not necessarily to everyone’s liking.

Nestled between the base Kobra and the hulking Max, Anycubic Kobra Plus offers makers a middle-ground large format printer geared for versatility. It rivals the likes of the Creality CR10 but at a much more competitive price point.

It capably handles bigger prints like large busts, sizable articulated print-in-place pieces, helmets, and the same range of more modest projects as its smaller sibling.

It borrows a few features from the Kobra, such as automatic mesh bed leveling, frame design, and color scheme.

But the Kobra Plus also draws inspiration from Anycubic’s other snakey printer, the Vyper, best illustrated by an almost identical Bowden extruder setup, ED3 Volcano-inspired hot end, pressure ABL strain gauge, and print head assembly.

Elsewhere, the Anycubic Kobra Plus drafts in a carborundum glass build plate. Not necessarily to everyone’s liking, but a viable alternative to the Kobra’s excellent flexible plate. Anycubic also veered away from the smaller Kobra’s blueprint by throwing in filament run-out detection, dual Z rods, and a side-mounted spool holder to accommodate the extra print capacity.

Anycubic Kobra Max

Pros

Same features and hardware as the Kobra Plus.

Sturdier frame and larger print volume.

Cons

Higher price.

The Anycubic Kobra Max is effectively a Kobra Plus – same features, hardware, a design – with a larger, sturdier frame and the print capacity supersized to a dizzying 400 x 400 x 450 mm. Placed alongside the Kobra, the Max dwarfs Anycubic’s entry-level offering with a massive footprint.

The Anycubic Kobra Max aims to offer an ultra large-format printer but updated with modern comforts and quality-of-life features, like automatic bed leveling, and out-of-the-box that simply aren’t available on similarly-sized FDM machines. The idea is to cater to what is still a relatively niche corner of 3D printing at a comparatively affordable price point.

Anycubic Kobra vs Kobra Plus vs Kobra Max Comparison

Build Volume

| Anycubic Kobra | Kobra Plus | Kobra Max |

|---|---|---|

| 220 x 220 x 250 mm | 300 x 300 x 350 mm | 400 x 400 x 450 mm |

Although the Kobra’s 220 x 220 x 250 mm build volume feels small compared to the Kobra Max, there’s enough capacity for all those classic first-timer projects. Think Warhammer miniatures, modest vases, small storage solutions for a retro gaming collection, printed 3D printer upgrades, jewelry like earrings, toothpaste squeezers, and soap dishes.

The Anycubic Kobra Plus pushes print capacity to 300 x 300 x 350 mm while keeping to a reasonably sized machine footprint. This makes it a strong option for those who want extra versatility to print larger pieces, for example, a Master Chief helmet in one sitting, but don’t want to rearrange their whole workshop or bedroom to fit the printer.

The Anycubic Kobra Max’s 400 x 400 x 450 mm gears itself towards the uncompromising maker that wants the freedom to undertake both small and absolutely massive projects – everything from detailed terrain for tabletop gaming to wearable cosplay armor and weaponry.

Verdict: go with the bigger build volume if you plan to print big.

Print Surface

The Anycubic Kobra features a PEI-coated flexible magnetic spring steel sheet. The upper layer is coated with a rough texture to ensure strong first-layer adhesion.

Prints stick with little effort and pop off just as easily with a simple flex of the surface. The flip side is this leaves a grainy, potentially unsightly finish on every print’s initial layer, which can sour first-layer detail.

The Anycubic Kobra Plus and Max have the same tempered carborundum glass print bed (sized to their respective build volumes) secured with metal clips.

It’s layered with Anycubic’s proprietary Ultrabase microporous coating to ensure ultra-smooth first layers and fantastic adhesion. Though you won’t have the flexibility of a removable plate, left to cool, prints come off the bed with next to no effort.

Heated Bed

The Anycubic Kobra heated tops out at 110°C, while the Plus can reach up to 100°C, 10°C higher than the Kobra Max’s 90°C max bed temperature. The larger the build volume, the harder it is to quickly and efficiently produce heat, hence the drop-off in max temperature.

For PLA, TPU, and PETG, these variations in max bed temperature aren’t an issue – all three offer temperatures well within the optimum range for these materials.

However, for ABS, the Anycubic Kobra trumps the Kobra Plus and Max. The Plus and Max’s top bed temperatures sit on the lower end of what’s generally deemed appropriate for ABS.

All three printers offer uniform heat distribution across their beds to minimize heat-related issues like warping. Thanks to its compact size, the Kobra heats up quicker than the others. Again, nothing out of the ordinary given their size, and as heated beds go, the Max and Plus perform well and only take a handful of minutes to heat up.

Verdict: if you want to print high-temp materials, you accept a slower-to-heat bed, that’s just the trade-off. So pick the Kobra for quicker heating and a higher 110°C max temperature if that’s important to you.

Extruder

The Anycubic Kobra has a direct drive setup, meaning the extruder is mounted on the print head for a very short filament path to the hot end.

Direct drive makes for more controlled retraction performance and extrusion, which helps reduce common problems like stringing, ghosting, and filament snapping/clogging/jamming on its way to the nozzle. It’s generally favored by heavy users of soft and squishy filaments like TPU.

But this is at the cost of substantially more weight on the print head, which can mess with travel accuracy and slow print speeds.

Direct drive extruders are generally reserved for much pricier machines like the Prusa i3 MK3S+ and Flashforge Creator Pro 2, so not only is it surprising to see it on such an affordable printer, but Anycubic’s implementation is nothing short of superb. The typical movement issues don’t rear their head at all in our experience with the Kobra.

With the main aim being to minimize weight on print assembly, especially higher up in the build volume where wobble is most prominent, the Anycubic Kobra Plus and Max feature a Bowden setup.

A dual-gear extruder is fixed to the frame and feeds the filament through a long Bowden tube (hence the name) into the hot end. Consequently, the print head is lighter, theoretically reducing wobble and vibrations on the z-axis and allowing for faster print speeds and smoother travel movements.

Retraction performance suffers as a consequence, stringing being a notable issue. Without the proper tuning, filament deterioration in the tubing is also quite common on Bowden setups, especially with TPU and other flexible.

Verdict: TPU will be easier to print on the Kobra, but bowden extruders are generally lighter and can print faster with the Kobra Plus and Max.

Bed Leveling

All three printers feature Anycubic’s in-house-developed LeviQ automatic mesh bed leveling system.

We can nitpick and point to the Kobra’s inductive probe as being ever so slightly more accurate than the Max/Plus’ Vyper-inherited, nozzle-mounted strain gauge system, but in practice, the results are the same on all three printers – set-and-forget, hassle-free automatic bed leveling.

There is also LCD-controlled Z offset tuning on all three machines for when you need a little more squish or want to fiddle your way to a flawless torture test.

Material Compatibility

All three Anycubic Kobras support FDM standards PLA and ABS, along with PETG and TPU. So, nothing to set them apart in terms of manufacture-vetted material compatibility, and all excel when fed a spool of PLA.

Things get a bit more nuanced when it comes to ABS and TPU.

As we noted above, the Plus and Max’s heated beds only just reach temperatures we’d deem acceptable for ABS printing, while the Kobra hits that 105°C-110°C sweet spot.

Due to the open design of the printer, printing ABS on either of the printers without an enclosure will be nothing short of a feat of patience and determination. An enclosure is needed, like this one from Anycubic.

As for the TPU, the Kobra is slightly more favored for the better retraction performance provided by the direct drive setup. But, we’ve also seen solid print quality with surprisingly little stringing on the bigger Kobras, so the Plus and Max are certainly up for the challenge.

Verdict: Kobra’s direct drive is better for TPU, and higher print bed temp might make a difference with ABS.

Spool Holder

In more or less classic direct drive style, the spool holder is gantry-mounted on the Kobra, while Anycubic has shifted it to the left side of the printer on the Max and Plus to reduce weight on the upper frame.

Though we have no issue with the placement on the larger Kobras, the holder is dimensioned to hold 1 kg spools, which seems like an oversight.

Projects that make full use of their build volumes invariably require far more filament, so larger 2 kg or even 3 kg spools, which the holder won’t accommodate. You can, of course, 3D print an adapted spool yourself, but this is something to keep in mind if you want to tackle a jumbo project.

The Little Extras

The Anycubic Kobra Plus and Max include filament runout detection as standard. The printers will automatically pause and conserve print progress if they run out of filament or if the filament breaks. A useful feature, especially if you’re making full use of those large build volumes with dozen hour-long prints.

The Anycubic Kobra Plus also has a little extra that the others don’t: a tool drawer integrated into the bottom of the frame. Useful for storing tools, SD Cards, and other 3D printing accessories.

Price

- Anycubic Kobra – $299 — Available at Anycubic store here

- Anycubic Kobra Plus – $499 — Available at Anycubic store here

- Anycubic Kobra Max – $639 — Available at Anycubic store here

None of the three Kobras are overpriced for what they offer, delivering plenty of value at a competitive price point, often better than similarly specced printers from competing brands.

There’s no doubt Anycubic has continued its laudable run of good quality, feature-rich printers that won’t break the bank with the Kobra line-up.

The Anycubic Kobra is a clear winner if you’re on a budget. But, for those with more cash to spare and an unflinching appetite for chunky build volumes and big prints, the Kobra Plus and Max offer ample bang for your buck at their respective prices.

BUDGET PICK

Anycubic Kobra

Available at:

MID-RANGE PICK

Anycubic Kobra Plus

Available at:

HUGE PRINTER

Anycubic Kobra Max

Available at:

Anycubic Kobra vs. Kobra Plus vs. Kobra Max – Which is Best For You?

Priced at a budget-friendly $299, the Anycubic Kobra positions itself as the ideal first 3D printer for beginners. Few other printers offer the same features at this price, nor do they make it quite as easy to get consistent results from print to print.

Occupying the next rung up on the Kobra size ladder, the Kobra Plus serves up the same enjoyable experience and welcome specs as its sibling but gives makers additional capacity without resorting to supersized, mammoth footprints. A happy middle-ground printer for the modestly ambitious printer.

The Anycubic Kobra Max, on the other hand, is a perfect fit for ambitious makers looking to produce large prototypes, one-piece helmets, props, and pieces for cosplay. Few other consumer-grade printers offer so much capacity alongside trouble-free functionality and consistently solid print quality.

Related articles:

- Anycubic Kobra vs Anycubic Vyper 3D printer review

- Anycubic Photon M3 vs M3 Plus vs M3 Max

- Anycubic Mega X vs Mega S vs Chiron vs Mega Pro

- The best Anycubic 3D printers – ranked

- Anycubic Mono X vs Elegoo Saturn

- Elegoo Mars vs Anycubic Photon

- Anycubic Kobra Plus/Max or Ender 5 Plus or Sovol SVO3: Which to Buy