How To Fix Filament Sticking To Your Nozzle

At 3DSourced we’ve covered everything 3D printing and 3D since 2017. Our team has interviewed the most innovative 3D printing experts, tested and reviewed more than 20 of the most popular 3D printers and 3D scanners to give our honest recommendations, and written more than 500 3D printing guides over the last 5 years.

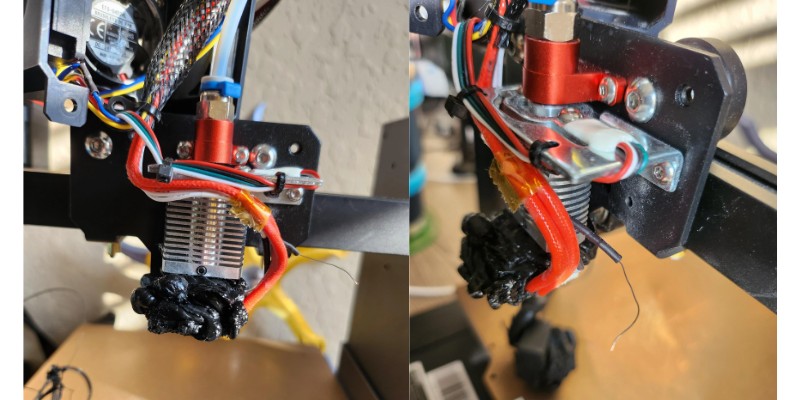

One of the most frustrating and even harmful problems you might run into is your 3D printer filament sticking to the nozzle.

There are a few reasons why this could happen, depending on your specific printer and your filament.

I’ll explain the various causes of filament nozzle issues, as well as the solution for each issue to your filament sticking to the extruder. Even reliable printers like the Ender 3 suffer from filament getting stuck to the nozzle from time to time, but fortunately it’s not too difficult to fix.

So regardless of why this is happening to you, we’ll get you back and 3D printing smoothly and confidently in no time.

- Why is Your 3D Printer Filament Sticking to the Nozzle?

- Effects of Filament Sticking to the Nozzle

- How to Prevent Filament from Sticking to the Nozzle

- Unclog the Nozzle

- Check Nozzle Temperature

- Make Sure the Print Bed is Level

- Adjust Print Speed

- Switch to a Higher Quality Filament

- Upgrade Your Nozzle

- Troubleshooting Tips for Each Kind of Filament Sticking to the Nozzle

Why is Your 3D Printer Filament Sticking to the Nozzle?

There are a few reasons why filament could be sticking to the nozzle, including filament clogging in the nozzle, incorrect extrusion temperature settings for your material, and damaged or low-quality filament.

Here we’ll look at each cause to help you figure out which one you’re dealing with, and how to fix it quickly and efficiently.

Clogged Nozzle

A clogged nozzle can lead to a host of 3D printing problems, including filament sticking to the nozzle. A clogged or even partially-clogged extruder prevents filament from being released from the hot end efficiently.

Incorrect Nozzle Temperature

Different filaments have different optimal printing temperatures. If you’ve not set your temperature within the recommended range, you’ll find yourself running into a lot of problems when printing, including the filament sticking to the nozzle.

This happens because the filament isn’t being properly melted to a hot enough temperature, meaning it’s too cool when it comes out. If it’s not hot enough, it will cool far too early and stick to the nozzle before being applied to its intended layer.

Low Quality and Damaged Filament

Filament bought on the cheap may seem like a frugal way to keep 3D printing, but it’s important to ensure you’re getting good quality filament to avoid disappointment and wasted money in the long run.

Low-quality filament is more likely to string, not adhere properly, and also stick to the hot-end in a way that will become problematic over time.

You’ll also run into these issues if you’ve allowed your filament to diminish in quality by absorbing too much atmospheric moisture or become too dusty – as some filaments are very hygroscopic.

Effects of Filament Sticking to the Nozzle

If your filament is sticking to the nozzle, it won’t have adequate space to properly extrude and will come out mishappen and at speeds and temperatures that are detrimental to your print.

Think of it like putting your thumb over the nozzle of a hose: the water will be forced to come out at incorrect pressures and at a wrong angle, spraying where it shouldn’t. This is exactly what happens to your filament when the nozzle is in any way clogged.

This, in turn, will lead to stringing, poor adhesion, and failed or warped print. If unfixed, it will lead to a build-up of pressure that can cause irreparable damage or even become dangerous.

How to Prevent Filament from Sticking to the Nozzle

Now that you know what’s causing your 3D printer filament to stick to the nozzle, let’s take a look at a few ways to fix the problem, depending on which problems you’re facing.

Unclog the Nozzle

Unclogging the nozzle is the first step to reducing the likelihood of your filament sticking to your nozzle. This helps ensure your filament extrudes exactly as it needs to for reliable prints and smooth projects.

There are several ways to unclog a stuck nozzle.

The easiest and safest way is to use a very thin object like a medical or acupuncture needle or guitar sting to dislodge any clogged filament as easily as cleaning pocket lint out of a phone jack.

Just be sure to turn off your 3D printer, and make sure it’s completely cooled down, before attempting this.

Another method is called cold pulling. This involves manually feeding filament through the nozzle to help remove stuck filament on the inside of the nozzle from top to bottom, similar to how running water through a funnel will clear whatever liquids are still on its edges.

For more superficial clogs and filament stuck to the nozzle’s hot end, a simple once-over with a wire brush or ball of steel wool helps get rid of any stuck filament.

For a more detailed rundown on the effects, causes, and solutions, we’ve also written an in-depth article on fixing clogged 3D printer nozzles.

Check Nozzle Temperature

If you’re using the wrong (specifically, too cold) temperature setting for your filament, then your filament will cool too quickly and stick to the nozzle.

To fix this, simply adjust your extruder temperature settings to match those recommended by the filament manufacturer. When in doubt, simply increase the temperature in 5℃ increments until the filament comes out smoothly.

For the best results, always stay within the filament brand’s recommended temperature range. Beyond that, these are the temperature ranges for the most common filaments:

- PETG: 230 – 260℃

- ABS: 230 – 250℃

- PLA: 190 – 210℃

- TPU: 210 – 240℃

Make Sure the Print Bed is Level

An uneven print bed will mean that in certain places, the nozzle will be too close to the build surface, reducing the space the filament has to be extruded.

When this happens, some filament will be stuck, and cool while still touching the nozzle.

If you’re lucky enough to have a 3D printer equipped with automatic leveling, then this shouldn’t be a problem. But if not, all you need to do is insert a thin piece of paper between the nozzle and the print bed and check that they remain equidistant in all four corners of the built plate.

If not, simply adjust the bed until it all lines up, and you’ll be good to go.

Leveling your print bed not only reduces the risk of filament sticking to the nozzle, but will also help ensure reliable and successful prints, so it’s a handy thing to keep in mind throughout your 3D printing adventures.

Adjust Print Speed

If you’ve got your print speed set too high, then the filament may not have the time to heat up, and stick to the nozzle as it cools far too quickly.

The rule of thumb is that the slower the print speed, the more reliable the print, and the less likely you are to run into long-term problems, including 3D filament sticking to the extruder.

To fix this, simply lower the print speed incrementally until you find your 3D printer working smoothly and without incident.

The longer wait time is worth the hassle-free printing, I promise.

Switch to a Higher Quality Filament

Low-quality or damaged filaments will not print as efficiently as they should, which can lead to a host of problems including warping, stringing, and nozzle-sticking.

3D printer filaments are hygroscopic, meaning they’ll absorb moisture over time and worsen in quality. Taking good care of it will help with more reliable printing, and lower the chance of warping and sticking to the nozzle.

Always make sure your filaments are within their use-by date, are stored away from sunlight, and safe from airborne moisture in proper filament storage.

Upgrade Your Nozzle

Standard 3D printer nozzles generally work well on the outset, but as you use your 3D printer more, you may want to consider upgrading yours, especially if the one that came with your printer becomes damaged or is even of lower quality than you’d like.

Most nozzles included with 3D printers are made of brass, which will wear over time even if you’re careful with them, particularly if you’re using especially abrasive filaments. Upgrading to a steel nozzle will breathe new life into your 3D printer, and will last far longer than typical brass ones. For more information, we have a full article on the best 3D printer nozzle upgrades.

Troubleshooting Tips for Each Kind of Filament Sticking to the Nozzle

If you notice that you only seem to face nozzle-sticking issues with one particular filament, then you can zero in on the problem with more specific fixes.

Here are the top 3D printer filaments for home use and how to make sure they don’t stick to the nozzle in the future.

PETG

PETG nozzle build-up is one of the more common problems people find with it, but it can be easily avoided.

Make sure you stay within the recommended extruder temperature of 230 – 260℃ to keep it running smooth, though we recommend starting at around 240℃ and increasing it incrementally if you find it’s not printing well.

The most important thing to remember when printing with PETG is that it needs a good amount of space between the nozzle and the print bed to avoid it sticking to the nozzle. Try to maintain a nozzle height of no less than 0.1mm for the best results.

ABS

ABS is a great filament, but it’s also one of the most problematic. The best way to make sure the filament extrudes where it needs to and doesn’t stick to the nozzle is to maximize first-layer adhesion.

The best way to do this is to use a good adhesive and print at lower speeds to make sure the initial layers create a reliable base for the rest of your project.

PLA

Unlike PETG, PLA actually benefits from a reduced layer height. While 0.1mm should work well, you can go lower (to around 0.05mm) if you find the extrusion to be unreliable or problematic.

Overall, PLA sticking to the nozzle is an easily solvable problem, just be sure it isn’t too cool. Staying around 200℃ with PLA should keep things running smoothly.

TPU

TPU is a softer material than most, and the best way to keep it from sticking to the nozzle is to make sure it doesn’t cool too quickly.

Printing at slower speeds (typically around 15-20mm/s) and with an extruder temperature of about 230℃ will significantly increase extruder efficiency and reduce the chances of sticking and clogging.

It also helps to keep a layer height of about 0.2mm for the best results.